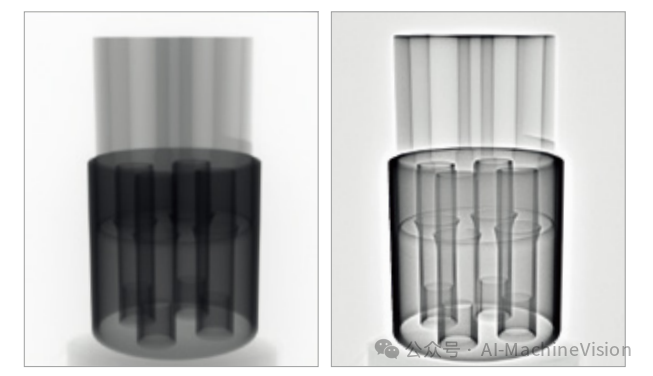

Industrial computed tomography (TIC) is a technology that uses x-ray imaging technology to perform non-destructive inspection of objects. The basic principle is that when a beam of collimated rays of energy I0 passes through the object to be inspected, due to the different attenuation coefficients of each volume element in each transmission direction, the detector records the information of attenuation, then processes the data through a computer to generate two- or three-dimensional tomographic images.

Principles of X-ray CT

It is a non-destructive testing technology that uses materials of different densities to have different X-ray absorption rates in order to transmit the tested part and reconstruct the image of the internal structure of the object on the external projection database.

two steps

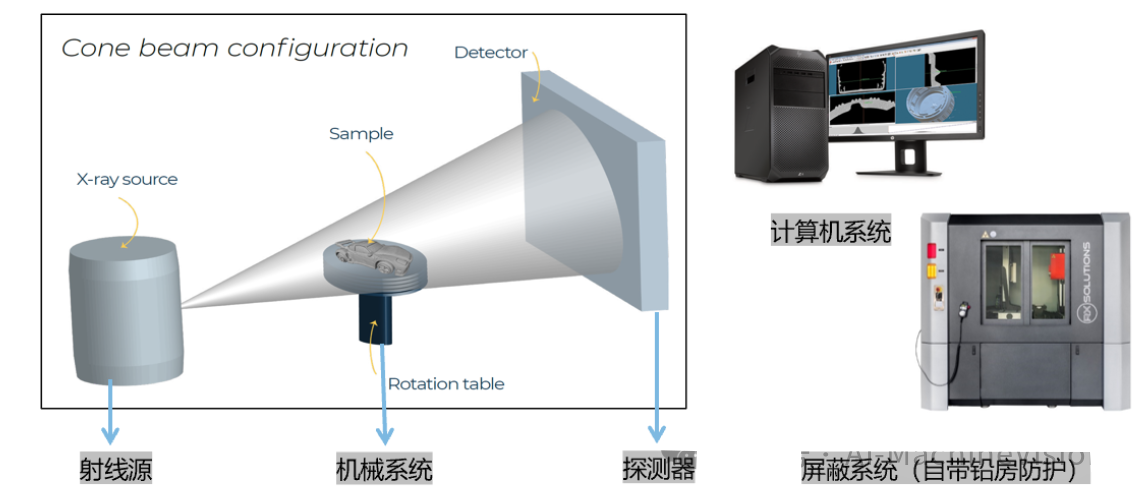

CT scanning requires two steps:

Acquisition: record hundreds of x-rays (or projections) of the sample as it rotates

Reconstruction: 3D reconstruction of the part by computer processing using a large number of slices

Factors Affecting Image Quality

Number of screenings

The duration of the scanner and the quality of the acquisition are directly linked to the number of projections. If we increase the number of projections, the image quality will be better.

average value

Image noise affects the quality level of observable details and therefore the precision of the acquisition. Increasing the average duration of a scan reduces noise levels and improves the signal-to-noise ratio: resulting in better imaging.

resolution

Resolution defines the level of size of details observable in an image. However, very high resolutions require longer scanning times. On small samples, the RXSolutions CT system can achieve resolutions of several hundred nanometers.

CT applications

CT scanning, the only non-destructive testing technology capable of seeing the inside of your sample!

Parts obtained by additive manufacturing require extensive monitoring and inspection efforts throughout the production process.

Computed tomography (CT) is a powerful non-destructive testing technology that allows each sample to be easily examined and is the only technology capable of seeing the inside of a substance. CT scanning can be used in many applications such as research and development, product development, manufacturing process optimization…

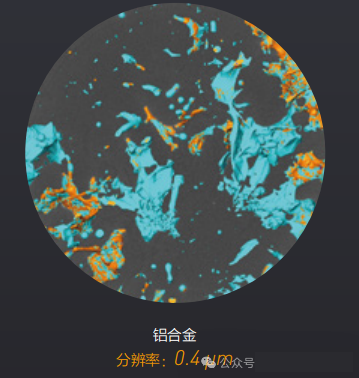

Analysis of the microstructure of materials

Submicron analysis of the internal structure of materials at very high resolution. In this sample we can observe intermetallic compounds of copper and iron.

Fields: materials science, geology, R&D phase, etc. Can be used for tensile testing and in situ fatigue testing

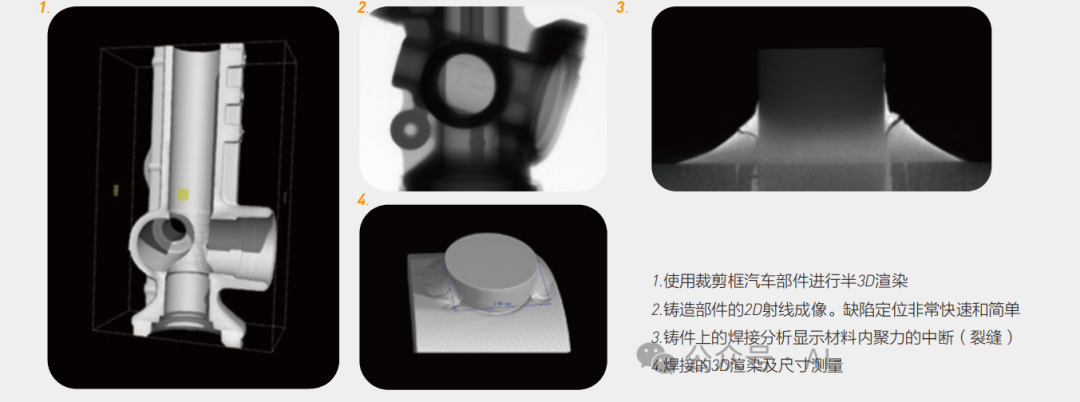

Dimensional measurement: Metrology

Dimensional measurements of the entire external and internal surface of the sample

Fields: automotive, aerospace, casting, machinery, electronics and other industries

CT scanning is the only technology capable of monitoring the surface dimensions of products in a simple way, even if they have complex and inaccessible patterns.

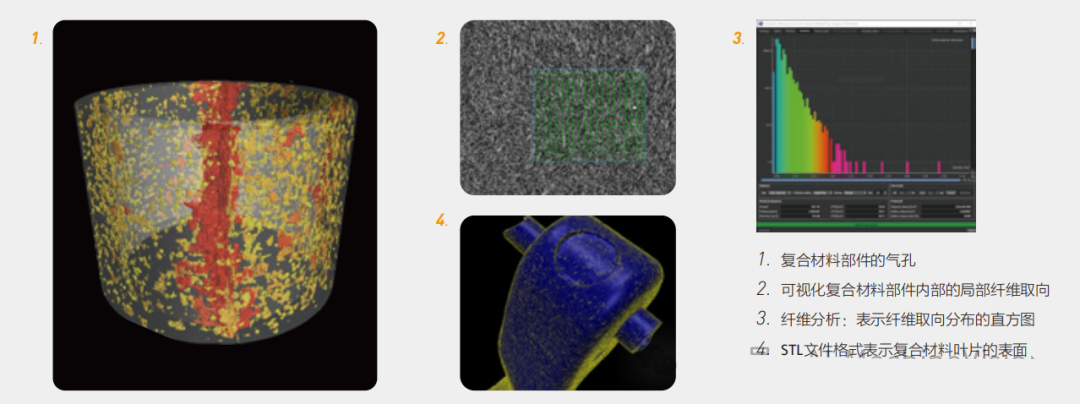

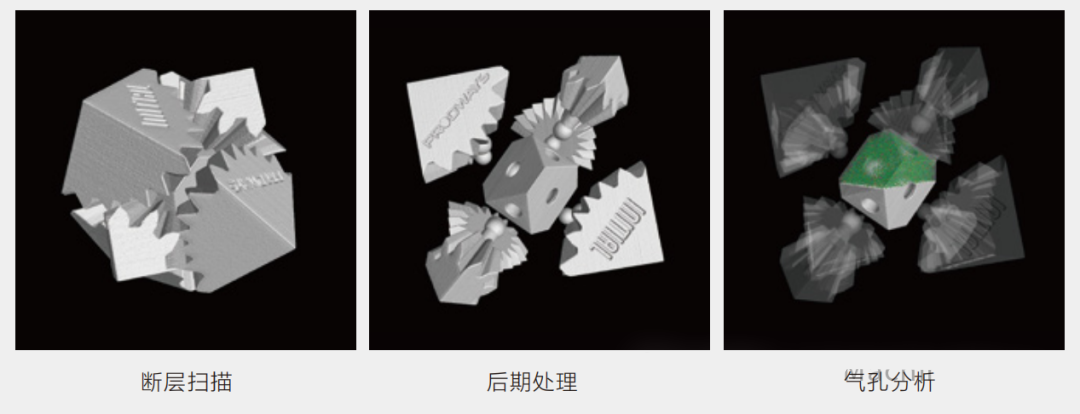

Defect analysis

Porosity, inclusions, cracks…

CT scanning makes it possible to obtain 3D volume data of the sample, which contains all defects using color codes, and to distinguish bubbles or inclusions by shape, size, etc.

Fields: aerospace, automotive, materials science, aluminum and injection molding or electronics and electrical industries

CT scanning offers the ability to quantify pores, inclusions, cracks or pits in a sample without cutting or damaging the sample.

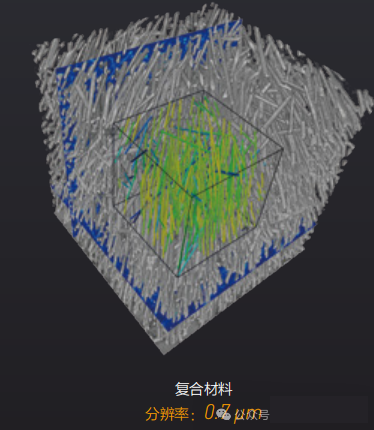

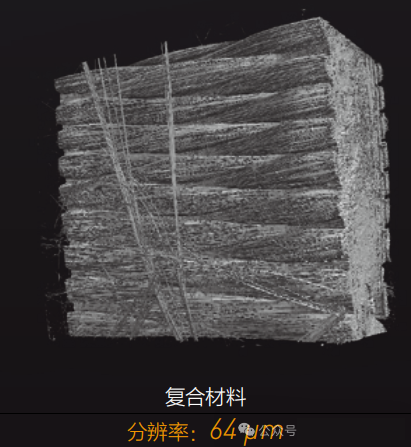

Internal structure analysis – fiber orientation

Fiber orientation analysis is very useful in the development and manufacturing process of composite materials, and with CT scanning, the fiber structure is clearly visible

Fields: Aviation, Automotive, Materials Science, Composite Materials, etc.

CT scanning makes it possible to quantify the mechanical and physical properties of the fibers in the part

Structural analysis: quality control verification

Industrial CT scanning of 3D printed parts can quickly and accurately inspect the internal structure of the part. Even on complex printed parts, accurate 3D models of samples can be exported to measure the internal and external geometries of single or multi-material printed parts.

CT equipment

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.