How To Start CNC Machining Business?

Starting a CNC machining business can be a rewarding venture, especially in today’s manufacturing landscape where precision and efficiency are paramount. If you’re considering taking the plunge, here’s a comprehensive guide to help you get started.

Understanding CNC Machining

Before diving into the business aspect, it’s crucial to understand what CNC machining is. CNC stands for Computer Numerical Control, which refers to the automation of machine tools via computer programs. This technology allows for precise control of complex machinery, making it ideal for manufacturing intricate parts.

Key Steps to Starting a CNC Machining Business

1. Market Research

Conduct thorough market research to identify potential customers and understand their needs. Look into industries that heavily rely on precision parts, such as automotive, aerospace, medical devices, and consumer electronics.

2. Business Plan

Create a detailed business plan outlining your business goals, target market, competition analysis, marketing strategy, financial projections, and operational plan. This will serve as a roadmap for your business.

3. Equipment Investment

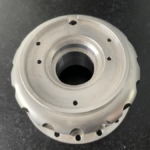

Invest in high-quality CNC machines. Consider starting with essential machines like three-axis CNC mills and lathes. As your business grows, you can expand to more advanced machines like five-axis CNC machines for complex parts.

4. Location and Facility Setup

Choose a location that is convenient for your customers and suppliers. Ensure your facility is equipped with necessary safety measures and has adequate space for machinery and storage.

5. Hiring and Training

Hire skilled machinists and CNC programmers. Provide ongoing training to keep their skills up-to-date with the latest technologies and practices.

6. Quality Control

Implement a robust quality control process to ensure your parts meet the required standards. This includes using precision measurement tools and conducting regular inspections.

7. Marketing and Sales

Develop a marketing strategy to attract customers. Utilize online platforms, social media, and industry events to promote your services. Networking with potential clients and partners can also be beneficial.

8. Compliance and Certifications

Ensure your business complies with industry standards and regulations. Obtaining certifications like ISO 9001 can enhance your credibility and attract more customers.

Choosing the Right Partner

When starting a CNC machining business, choosing the right partner is crucial. GreatLight CNC Machining Factory is a prime example of a reliable partner with extensive experience in precision parts machining and customization. With advanced five-axis CNC machining equipment and production technology, they specialize in solving metal parts manufacturing challenges and providing one-stop post-processing and finishing services.

GreatLight CNC Machining Factory has been in operation since 2011, located in Chang’an District, Dongguan City, China. They cover an area of approximately 7600 square meters and employ 150 skilled workers. Their facility is equipped with 127 pieces of precision peripheral equipment, including large high-precision five-axis, four-axis, and three-axis CNC machining centers, lathes, milling machines, grinding machines, EDM machines, vacuum forming machines, and various 3D printers.

Conclusion

Starting a CNC machining business requires careful planning, investment in quality equipment, and a commitment to excellence. By following the steps outlined above and choosing a reliable partner like GreatLight CNC Machining Factory, you can set yourself up for success in the precision parts machining and customization field.

For more information on how GreatLight CNC Machining Factory can support your business needs, visit GreatLight CNC Machining Services.

Frequently Asked Questions (FAQ)

Q: What is CNC machining?

A: CNC machining is a manufacturing process that uses computer-controlled machines to create precision parts from various materials.

Q: How much does it cost to start a CNC machining business?

A: The cost can vary widely depending on the equipment, facility, and location. It’s essential to create a detailed budget and business plan.

Q: What certifications are important for a CNC machining business?

A: ISO 9001 is a key certification that ensures product quality meets international standards. Other relevant certifications include ISO 13485 for medical devices and IATF 16949 for the automotive industry.

Q: How do I find customers for my CNC machining business?

A: Conduct market research to identify potential customers in industries like automotive, aerospace, and medical devices. Utilize online platforms, social media, and industry events to promote your services.

Q: What is the importance of quality control in CNC machining?

A: Quality control ensures that parts meet the required specifications and standards, reducing the risk of defects and enhancing customer satisfaction.

For more insights and case studies, you can also explore GreatLight CNC Machining Factory’s presence on LinkedIn.