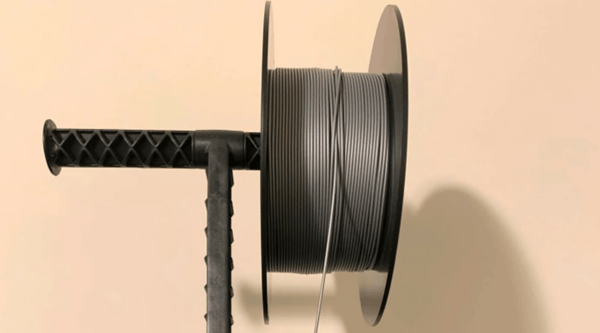

3D printingWrapping is an important but often overlooked part of 3D printing. There is usually nothing to worry about as the filament usually comes out of the box perfectly tangled. Correct wire winding is the basis of a good 3D printing experience and can avoid problems such as underprinting, vibration and errors.

However, when filament tangles occur, it can be an unbearable nightmare and even more complicated to resolve. But it doesn’t have to be that way! Here are some tips and tricks to help you prevent and resolve filament tangles on your spools and get the most out of your3D printer.

No one wants to see this (or face the consequences) (Source:neosnap via Reddit)

Filament tangles can be an annoying problem at best and a dangerous problem at worst. Before we look at what causes this problem and how to fix it, let’s look at why it’s important to avoid it.

An expected result of filament entanglement is that if the extruder is unable to push the filament, the print will be interrupted. This may be due to the knot preventing the spool from unwinding. This problem wastes time, energy, and materials, which can be costly if you’re printing on a deadline.

It is possible for a 3D printer to overcome small tangles on its own, but it is not without its problems. This can still cause a lot of vibration in the printer and printouts, because if the filament is hanging off the machine, loosening the tangles will cause the filament to move back and forth. This also wears out the motors and drives, as the motor requires more force to pull the tangled filament.

If you are using a custom spool holder such asTUSH) and the line is heavily tangled, the machine may continue to pull and drop the spool, resulting in potentially dangerous accidents and damage.

Additionally, filament tangles can cause other problems with the printer, because once the filament stops being pushed, the melted filament will stay inside the nozzle, eventually clogging the nozzle. The extruder pulley can also eat through the filament and damage it because it is stuck and unable to pull.

Finally, if you decide to continue printing with tangled filament, you will need to monitor the machine throughout to ensure nothing is happening and intervene to get any tangles near the extruder.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.