The most direct way to upgrade the treatment capacities is to upgrade the equipment, but the different parts of the treatment must always cooperate with each other. For example, we already have a 5 -axis DMG DMG machine tool, which has the capacity to treat parts with a diameter of 840 mm, a length of 500 mm and a maximum weight of 600 kg, and produces a variety of parts Irregular, including round, rectangular and geometric shapes. The traditional three -ingots mandrel cannot meet the needs and must find a safe, fast and flexible tightening method to ensure the effective operation of the new machine.

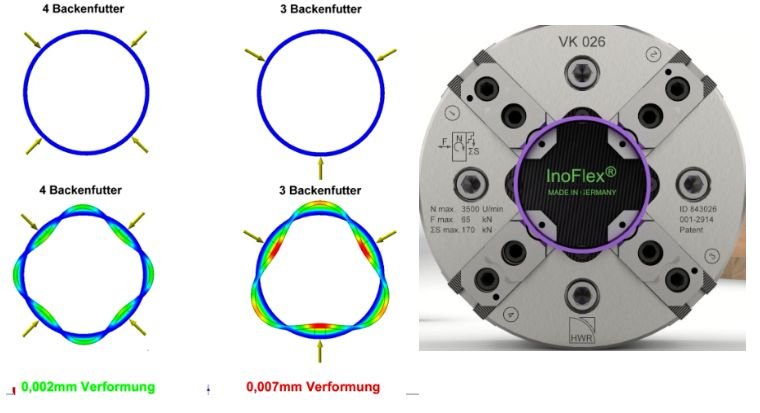

▲ four -mouth chuck

Floating tightening

The following tightening method is worth learning for easily distorted parts and a diversified combination of tightening parts, the floating centering certificate can solve the problem of processing irregular rectangular parts and geometric.

▲ To center floating tightening

▲ Easy to content clips

▲ Prepare the square, round and asymmetrical

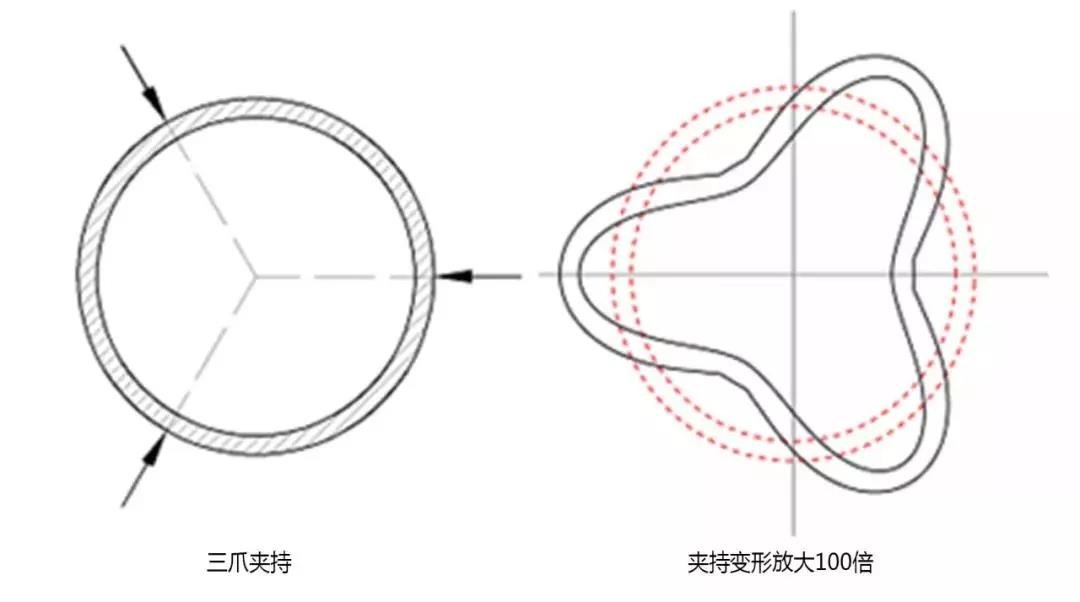

Treatment of easily distorted thin walls

Among the solutions to the problem of tightening parts in thin walls, the increase in the number of tightening points is one of them. If there is a simple method that can double the number of tightening points of the chuck without replacing the chuck, is it possible?

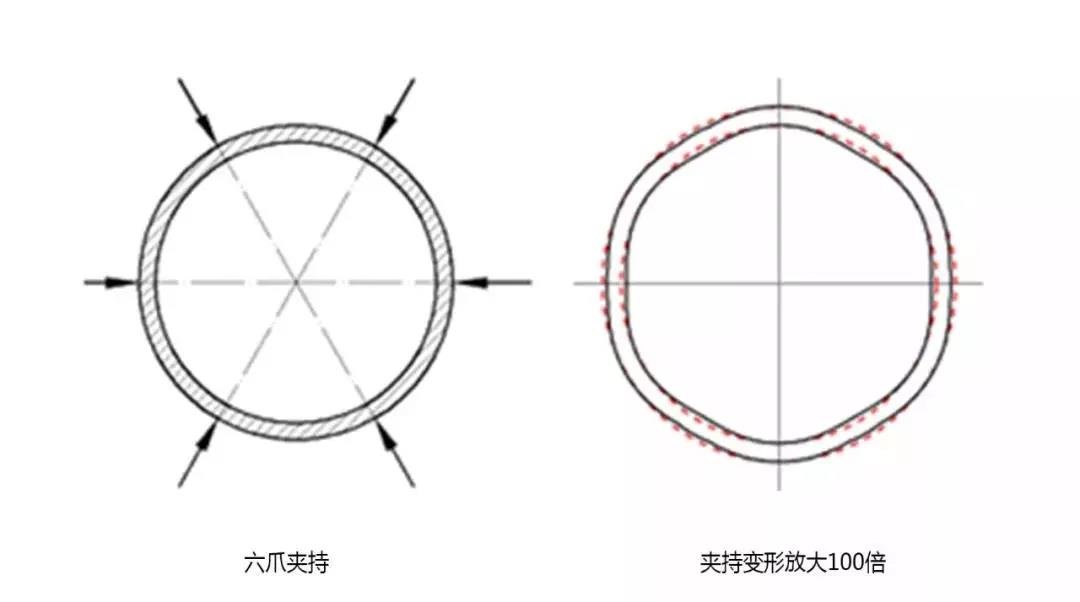

After being assembled with floating claws, the traditional three sludge covered can easily obtain a six sludge tightening, and the tightening diameter can be quickly adjusted in a large range, which reduces not only the deformation of the part , but also save the tightening of the part.

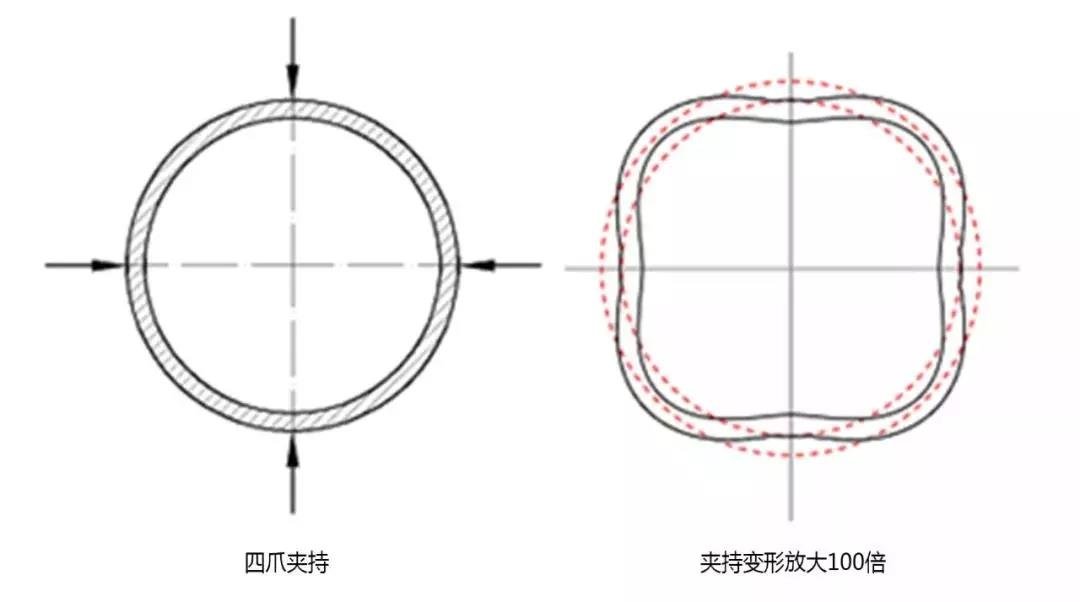

Six vaults pliers and eight caps

Applicable objects of floating claw systems include non -round parts on the surface or deformed parts after heat treatment. After use, the traditional three -ingots mandrel can perform the function of a six -mouth mandrel. The mechanical floating mechanism of the integral slide performs a reliable tightening of floating to six points, effectively reducing the deformation of the part. The tightening diameter range can also be adjusted in a large beach to adapt to tightening parts of different sizes. The use of floating claws on the four -grid floating mandrels can make tightening in eight points of parts with thin walls. Currently, the tightening deformation of the part can be reduced to a tenth of the three -point tightening.

Comparison of the amount of the deformation

Thanks to engineering software, the working conditions are simulated and the force analysis is: when tight by three claws, the inner roundness of the part after the deformation is 0.365 mm:

When you tighten the six jaws, the inner roundness of the part after deformation is 0.020 mm:

When you tighten the four claws, the inner roundness of the part after deformation is 0.105 mm:

When you tighten the eight jaws, the inner roundness of the part after deformation is 0.010 mm:

From this, we can see that the most tightening points, the deformation of the parts with thin walls will be effectively controlled. The tightening of traditional, round and special square parts and parts with easily distorted thin walls is made in different ways.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.