How to judge whether the number of cutting edges of a tool is appropriate? Whether a tool has the correct number of cutting edges depends on several factors, including the material being processed, the type of machining, the size of the tool, the cutting parameters as well as the precision and required machining efficiency. Here are some ways to determine if a tool has the correct number of cutting edges:

1. Consider treating materials

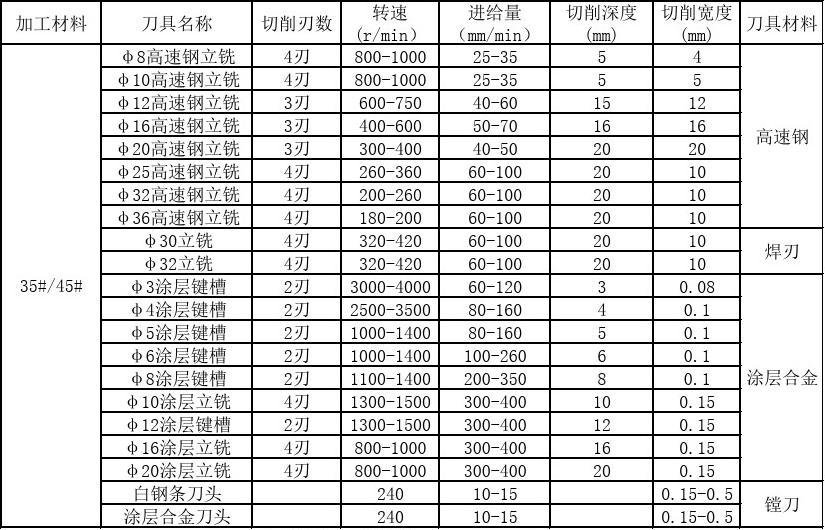

Different materials have different requirements for the number of cutting edges. For example, a harder material may require more cutting edges to distribute cutting forces, while a softer material may require fewer cutting edges to avoid overcutting.

2. Consider the type of treatment

Different types of processing (such as roughing, finishing, drilling, milling, etc.) have different requirements for the number of cutting edges. For example, when roughing, more cutting edges can improve machining efficiency, while when finishing, fewer cutting edges can be more conducive to achieving machining efficiency. ‘a better surface condition.

3. Consider tool size

The size of the tool also affects the choice of the number of cutting edges. Larger tools can generally accommodate more cutting edges, while smaller tools may be limited by space and can only have fewer cutting edges.

4. Consider cutting parameters

Cutting parameters such as cutting speed, feed and cutting depth also affect the choice of the number of cutting edges. Higher cutting speeds and feeds may require more cutting edges to maintain a stable cut.

5. Consider processing accuracy and efficiency

If greater machining precision is required, you may want to choose a tool with fewer cutting edges to provide greater control of the cutting process. If you are looking for machining efficiency, you may need more cutting edges to increase the material removal rate.

6. Refer to the tool manufacturer’s recommendations

Tool manufacturers generally provide a recommended number of cutting edges based on the design and use of the tool. Use these tips to help you choose the right knife.

7. Conduct trial cutting experiments

Before actual production, cutting trials can help you determine the number of cutting edges best suited for a specific machining task. Through cutting tests, you can observe the stability of the cutting process, the processing quality and the wear of the tools.

To summarize, determining whether a tool’s number of cutting edges is appropriate requires careful consideration of several factors, including processing materials, processing type, tool size, cutting parameters , processing accuracy and efficiency, etc. Test cutting and consulting the tool manufacturer’s recommendations can help you find the number of cutting edges best suited to a specific machining task.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.