In mechanical processing, for parts with high geometric accuracy and high surface quality requirements, especially when the materials are hardened steel, cemented carbide, ceramics, silicon, germanium, quartz glass and other hard and brittle materials, a complete milling process and grinding is required. process to achieve the required treatment effect.The shape contour processing is completed by the milling process. In order to further meet the size and shape requirements of workpieces and ensure the surface effect of the workpiece, the grinding process is used to achieve high precision and high surface quality processing.

✦ Composite processing solution for milling and grinding ✦

In order to improve the processing efficiency of these parts, a composite milling-grinding processing method has appeared in the industry. By performing milling and grinding in a single device, processes are merged and process flow is reduced.

Beijing Jingdiao relies on Jingdiao high-speed grinding center to apply milling and grinding composite processing solutions to many industries. Let’s take a look at the application of Beijing composites precision engraving, milling and grinding solutions.

✦ Application file ✦

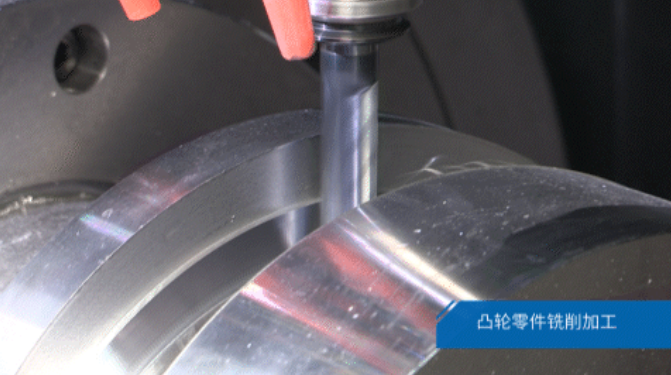

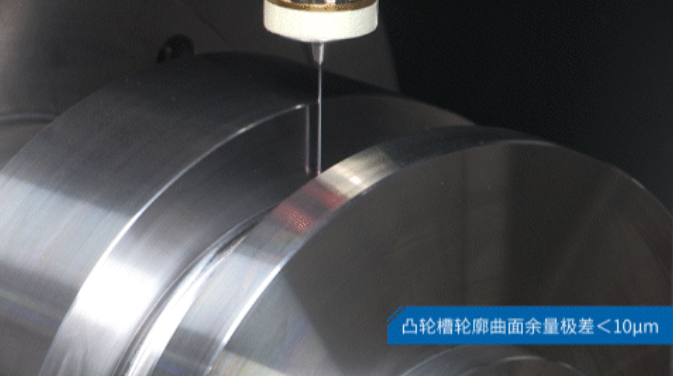

Cylindrical cam parts

machine tool:

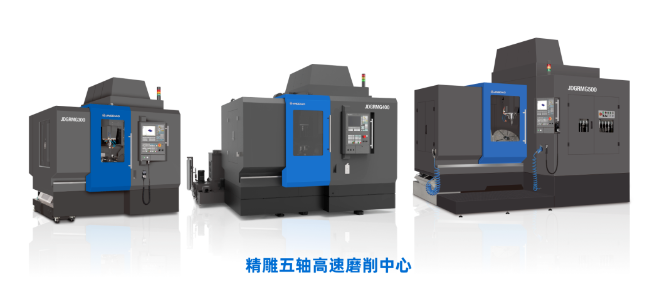

JDGRMG500 Precision Carving Five Axis High Speed Grinding Center

Treatment effect:

+The cam groove contour surface margin is extremely poor <10μm;

+ Groove width tolerance ±10 μm;

+ Surface roughness Ra0.4 μm.

Silicone Ring Parts

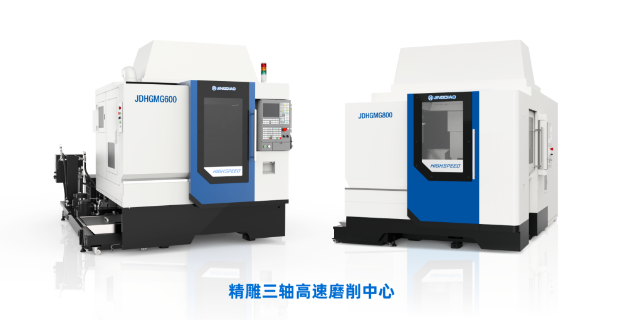

machine tool:

JDHGMG800 High Speed Three Axis Precision Grinding Center

Treatment effect:

+ Cylinder capacity of the rotating surface of the part < 10 μm;

+ Surface roughness Ra0.5 μm;

+The batch processing product yield rate is 99%.

femoral condyle prosthesis

machine tool:

JDGRMG400 Precision Carving Five Axis High Speed Grinding Center

Treatment effect:

+ Surface roughness Ra0.6 μm;

+ Deviation of the contour of the articular surface ±0.05 mm;

+Cutting marks in grinding and milling parts are less than 20 μm.

Why can Jingdiao high-speed grinding center achieve such processing effects? We will give you detailed answers immediately.

✦ Exquisite carving plan ✦

01Jingdiao high speed grinding center

Jingdiao high-speed grinding center, including five-axis high-speed grinding center and three-axis high-speed grinding center, has precision milling and grinding composite processing capabilities at the micron.

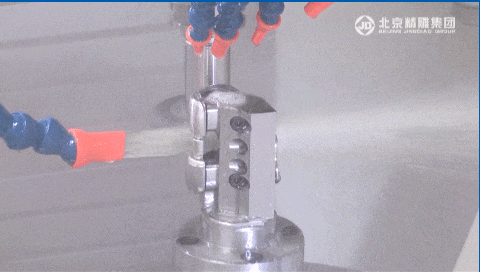

Milling

Sharpening

02Jingdiao on-machine inspection system

Jingdiao’s on-machine inspection system can perform tool and workpiece measurement during milling and grinding processes.

Control of tools on machine

During milling processing, the tool length, tool radius, tool profile and other parameters are tested on the machine to ensure that the precise tool size is used for the treatment.

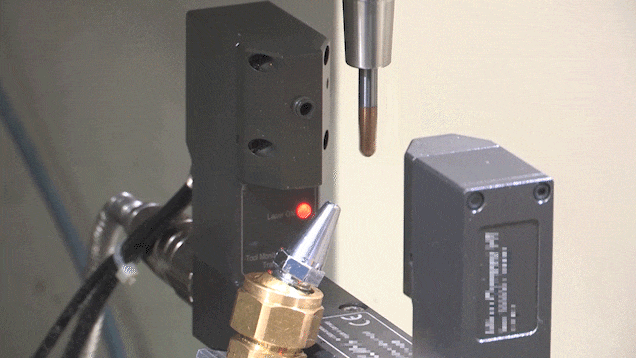

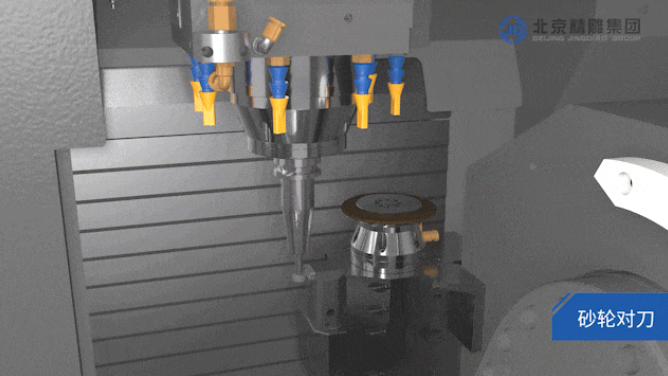

On-machine inspection of grinding wheels

For grinding wheels used in grinding processing, the diameter of the grinding wheel is accurately detected by the professional grinding wheel tool adjuster produced by Jingdiao to ensure that the precise diameter of the grinding wheel is used for grinding.

Inspection of parts on machine

The machine automatically performs incoming material inspection, process inspection and finished product inspection of parts to ensure that the parts are qualified as soon as they come out of the machine.

03Configuration of key components and accessories

Considering the characteristics of the grinding process in milling and grinding composite processing, it is equipped with key components and accessories developed by Jingdiao to accurately execute micron-level processing technology.

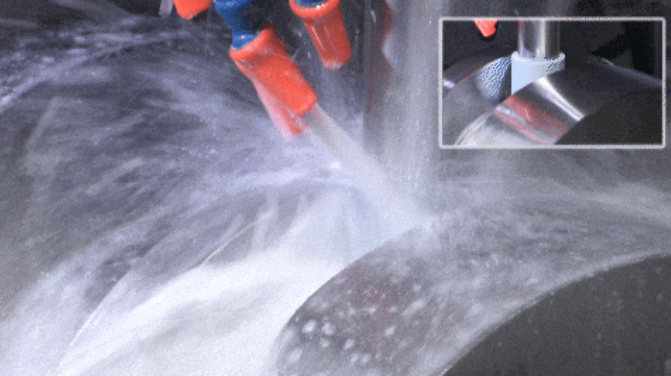

Jingdiao high speed precision electric spindle

In order to reduce the impact of the large amount of heat generated during grinding on the precision of workpieces, Jingdiao’s high-speed precision central water electric spindle is used to completely cool the grinding tools and workpieces so as to to guarantee grinding at micron level.

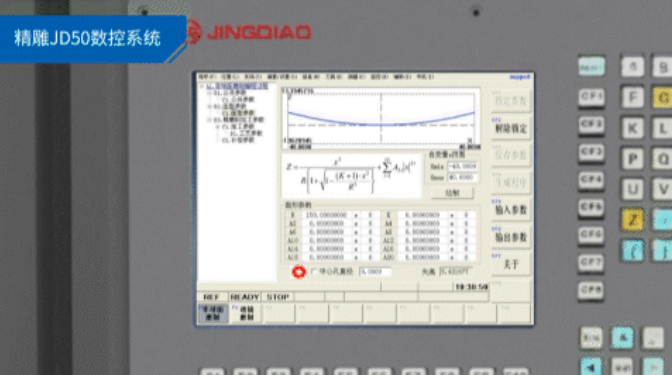

Jingdiao JD50 CNC system

Equipped with Jingdiao JD50 CNC system, it supports the use of different grinding tools for grinding processing.

For grinding spherical/aspherical parts, a parametric grinding programming module is also provided to improve the smoothness of grinding motion by eliminating nodes from the processing path.

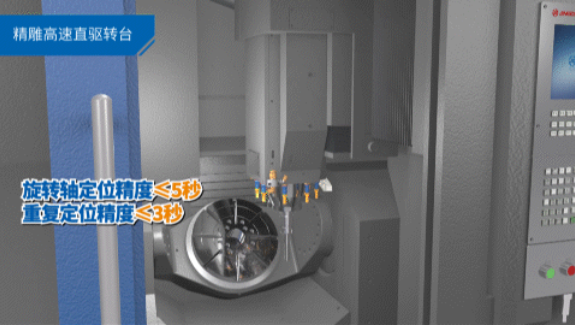

Jingdiao high-speed direct drive turntable

In order to ensure the precision of workpiece grinding, a high-precision direct-drive turntable is configured to realize high-precision five-axis linkage and five-axis positioning grinding.

Jingdiao ultrasound-assisted treatment technology

In order to improve the surface quality of parts and extend the life of tools, Jingdiao ultrasonic-assisted processing technology is used. This technology is based on the professional functions of Jingdiao high-speed grinding center and JD50 CNC system, and is realized by equipping it with suitable Jingdiao self-produced ultrasonic tool holders.

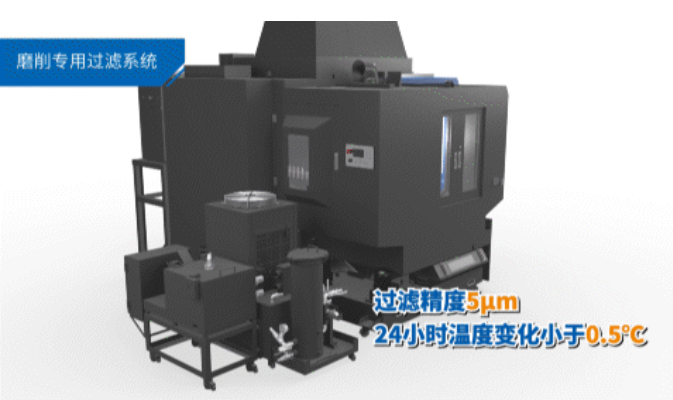

Precision grinding filter system

High-precision grinding places high demands on the processing environment. Firstly, it is necessary to ensure a constant temperature of the cutting fluid. Second, it is necessary to prevent tiny abrasive particles from contaminating the cutting fluid and affecting the surface quality of the workpiece. .

Equipped with a professional filtration system for chip removal with a filtration accuracy of 5 μm, it ensures clean cutting fluid, stable temperature and smooth supply.

✦ Summary ✦

Beijing Jingdiao milling and grinding composite processing solution uses Jingdiao high-speed grinding center to perform milling and grinding of all features in one device, and uses Jingdiao on-machine detection system to measure the workpiece during processing and tool measurement, combined. With the self-developed key components and accessory configurations for milling and grinding processes, we can accurately and efficiently realize the composite processing of milling and grinding parts at the micron level.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.