How To Build A Plasma CNC Machine?

In the world of precision parts machining and customization, a Plasma CNC Machine can be a game – changer. It offers high – precision cutting capabilities for various materials, making it a valuable asset for many manufacturing projects. If you’re considering building your own Plasma CNC Machine, here’s a comprehensive guide to help you through the process.

Understanding the Basics of Plasma CNC Machines

A Plasma CNC Machine combines Computer Numerical Control (CNC) technology with a plasma cutting torch. The CNC system controls the movement of the torch along multiple axes, allowing for precise and complex cutting patterns. Plasma cutting works by creating an electrical channel of super – heated, electrically ionized gas (plasma) between the torch and the workpiece. This plasma is extremely hot and can melt through metals like steel, aluminum, and stainless steel.

Essential Components

Frame and Structure

The frame is the backbone of your Plasma CNC Machine. It needs to be rigid and stable to ensure accurate cuts. You can use materials like steel or aluminum to construct the frame. Welding or bolting the components together can provide the necessary strength. For example, a rectangular frame design with cross – braces can offer good stability.

CNC Controller

This is the brain of the machine. It interprets the G – code (a programming language for CNC machines) and sends signals to the motors to control the movement of the torch. There are many types of CNC controllers available in the market, ranging from simple and affordable ones to more advanced and feature – rich models. Some popular options include the Mach3, LinuxCNC, and GRBL controllers.

Motors and Drives

Motors are responsible for moving the torch along the X, Y, and Z axes. Stepper motors or servo motors are commonly used in Plasma CNC Machines. Stepper motors are relatively inexpensive and easy to control, while servo motors offer higher precision and speed. Motor drives are used to power and control the motors based on the signals from the CNC controller.

Plasma Cutting Torch

The plasma cutting torch is where the actual cutting takes place. You can choose a torch based on the thickness of the materials you plan to cut. Different torches have different amperage ratings, which determine their cutting capacity. For thinner materials, a lower – amperage torch may be sufficient, while thicker materials require a higher – amperage torch.

Table and Workholding

The table provides a surface for the workpiece. It should be flat and sturdy. You can build a simple table using metal sheets or purchase a pre – made table. Workholding devices, such as clamps or magnets, are used to secure the workpiece in place during cutting.

Building Process

Design and Planning

Start by creating a detailed design of your Plasma CNC Machine. Consider the size, cutting capacity, and the materials you’ll use. Sketch out the frame dimensions, the placement of the components, and the overall layout. You can use CAD (Computer – Aided Design) software to create a 3D model of your machine, which will help you visualize the final product and identify any potential issues.

Frame Construction

Once you have the design, start building the frame. Cut the metal pieces according to the dimensions specified in your design. Weld or bolt the pieces together to form the frame. Make sure the frame is square and level to ensure accurate movement of the torch.

Installing the Motors and Drives

Mount the motors on the frame at the appropriate locations for the X, Y, and Z axes. Connect the motor drives to the motors and the CNC controller. Follow the manufacturer’s instructions for wiring and configuration.

CNC Controller Setup

Install the CNC controller software on your computer. Connect the controller to your computer using a USB or Ethernet cable. Configure the software settings according to the specifications of your motors, drives, and machine dimensions. You may need to calibrate the system to ensure accurate movement.

Plasma Cutting Torch Installation

Mount the plasma cutting torch on the torch holder. Connect the torch to the plasma power supply and the CNC controller. Adjust the height of the torch from the workpiece to ensure optimal cutting performance.

Workholding and Table Setup

Install the workholding devices on the table. Place the table in position and level it. You can also add a water – filled table to reduce smoke and debris during cutting.

Advantages of Building Your Own

Cost – Saving

Building your own Plasma CNC Machine can be more cost – effective compared to buying a pre – built one. You can source components at a lower cost and customize the machine according to your needs.

Customization

You have the freedom to customize the machine to suit your specific requirements. You can adjust the size, cutting capacity, and features of the machine to meet the demands of your projects.

Learning Experience

The process of building a Plasma CNC Machine is a great learning opportunity. You’ll gain a deeper understanding of how CNC technology and plasma cutting work, which can be beneficial for future projects.

Conclusion

Building a Plasma CNC Machine is a complex but rewarding project. With careful planning, the right components, and some technical skills, you can create a high – quality machine that meets your precision parts machining and customization needs. A well – built Plasma CNC Machine can open up new possibilities for your manufacturing projects, allowing you to cut complex shapes with high precision.

Frequently Asked Questions (FAQ)

How much will it cost to build a Plasma CNC Machine?

The cost can vary widely depending on the components you choose. A basic machine can cost a few thousand dollars, while a more advanced machine with high – end components can cost upwards of $10,000.

Is it difficult to build a Plasma CNC Machine?

It requires some technical knowledge and skills, especially in areas like welding, electrical wiring, and CNC programming. However, with the right resources and step – by – step guides, it is achievable for those with a basic understanding of mechanical and electrical systems.

What safety precautions should I take when using a Plasma CNC Machine?

You should wear appropriate safety gear, such as safety glasses, gloves, and a welding helmet. Make sure the work area is well – ventilated to prevent inhalation of fumes. Also, follow all safety instructions provided by the plasma power supply and torch manufacturers.

Can I use any type of plasma cutting torch with my CNC Machine?

You need to choose a torch that is compatible with the plasma power supply and the cutting requirements of your machine. Consider factors like amperage rating, torch size, and the type of materials you’ll be cutting.

How do I maintain my Plasma CNC Machine?

Regularly clean the machine to remove debris and dust. Check the motors, drives, and electrical connections for any signs of wear or damage. Replace any worn – out parts as needed. Also, follow the maintenance schedule provided by the component manufacturers.

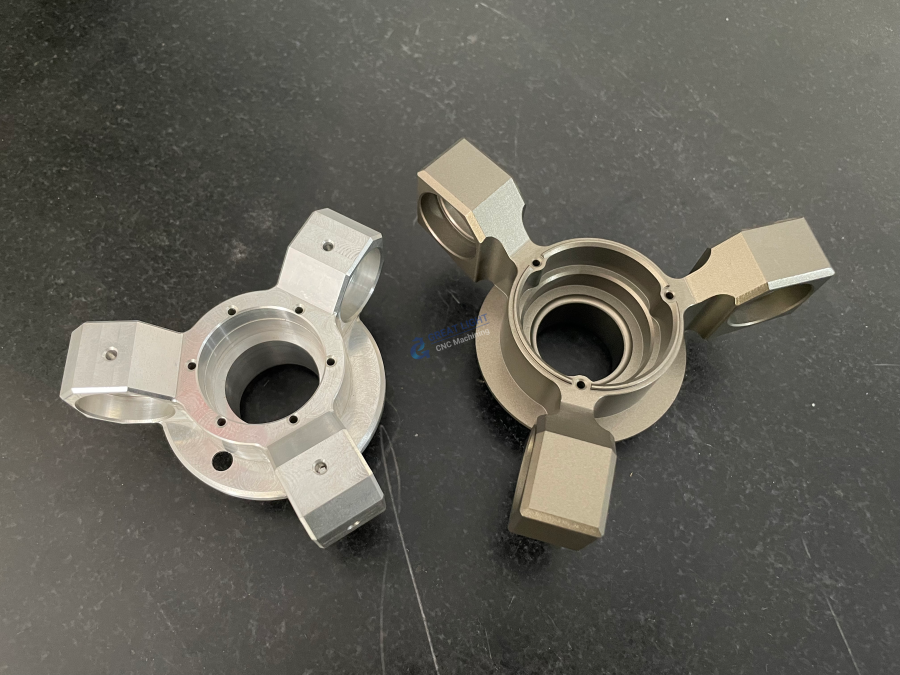

If you’re interested in high – quality precision machining services, GreatLight CNC Machining Factory is a professional five – axis CNC machining manufacturer. They have advanced equipment and production technology to solve metal parts manufacturing challenges. You can learn more about them on LinkedIn.