When evaluating CNC machining capabilities for your precision parts, understanding the machine’s axis configuration is fundamental. A common question that arises, especially when considering legacy or secondary market equipment, is: How many axis do Fadal CNC machines have? This inquiry touches on the core of machining flexibility, complexity handling, and ultimately, the suitability for your project.

Fadal Engineering, an American machine tool builder historically prominent from the 1980s through the early 2000s, produced a range of vertical machining centers (VMCs). The vast majority of standard Fadal VMCs, such as the classic models 4020, 4525, and 6030, were configured as 3-axis machines. This means they offered simultaneous control over the three linear axes: X (left-right), Y (front-back), and Z (up-down). This configuration is perfectly suited for a wide array of prismatic parts—components where machining primarily occurs from the top down, such as plates, brackets, housings, and molds with moderate complexity.

However, to address more complex machining needs, Fadal also offered 4th-axis rotary table options as a retrofit or integrated accessory. This added a rotary axis (typically the A-axis, rotating around the X-axis) to the standard 3-axis movement. With this, a Fadal machine could perform 4-axis machining, enabling indexed or continuous machining on multiple sides of a part in a single setup. This significantly improves accuracy for cylindrical features or parts requiring machining on their periphery, reducing setup time and potential errors compared to manual repositioning.

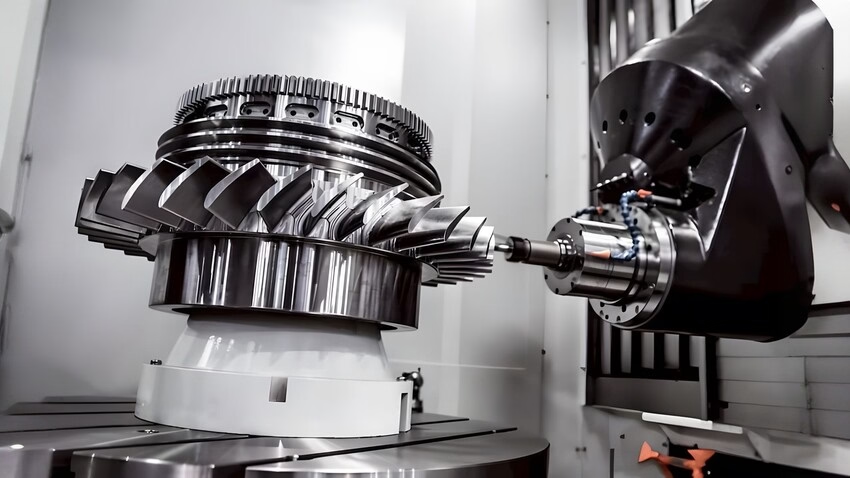

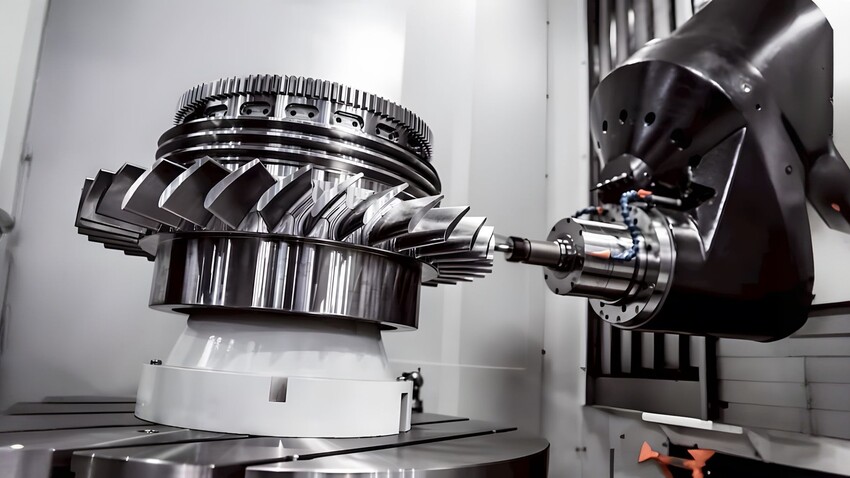

It is crucial to clarify that traditional Fadal machining centers were not manufactured as true 5-axis CNC machines. A 5-axis machine provides simultaneous control of three linear axes and two rotational axes (e.g., A and B, or A and C), allowing the cutting tool to approach the workpiece from virtually any direction in a single setup. This capability is essential for machining complex contoured surfaces, aerospace components, impellers, and precision medical implants. While some advanced modifications or special configurations might exist, the standard and widely recognized Fadal product line caps at 4-axis capability.

The Axis Evolution: From Fadal’s 3/4-Axis to Modern 5-Axis Solutions

The question about Fadal’s axes often stems from a broader need: determining the right technology for today’s precision part challenges. While Fadal machines built a reputation for rigidity and reliability in their era for 3-axis work, the advancement towards integrated, multi-axis machining has been transformative.

For clients requiring complex, monolithic components with compound angles, deep cavities, or undercuts, the leap to modern 5-axis CNC machining is not just an upgrade—it’s a necessity. This is where contemporary manufacturers like GreatLight CNC Machining Factory differentiate themselves. Unlike being limited to 3 or 4 axes, our core production relies on advanced 5-axis CNC machining centers. This allows us to tackle geometries that are impossible or prohibitively inefficient on traditional machines.

Consider these critical advantages of moving to a 5-axis paradigm for your custom parts:

Single-Setup Machining: Complete complex parts in one clamping. This eliminates cumulative errors from multiple setups, ensuring exceptional feature-to-feature accuracy and saving significant time.

Superior Surface Finish & Tool Life: The ability to optimally orient the tool relative to the surface allows for use of shorter, more rigid cutters, maintaining ideal cutting conditions. This results in better surface finishes and extended tool life.

Complex Geometry Mastery: Effortlessly machine intricate contours, organic shapes, and angled features that define modern aerospace, automotive, and medical device components.

Enhanced Drilling and Tapping: The spindle can be tilted to drill and tap holes at compound angles in a single operation, a task requiring complex fixtures on 3-axis machines.

Conclusion

So, how many axis do Fadal CNC machines have? Predominantly 3-axis, with common 4-axis configurations available via rotary tables. They represent a solid chapter in machining history for many applications. However, for forward-looking projects demanding the highest precision, geometric freedom, and efficiency, the capabilities of modern 5-axis CNC machining are indispensable. When your designs push boundaries, partnering with a specialist equipped with the right technology—like GreatLight CNC Machining Factory with our dedicated 5-axis machining services—ensures your vision is not limited by machine axes but fully realized through them.

Frequently Asked Questions (FAQ)

Q1: Can a 3-axis Fadal machine produce a part requiring 5-axis features?

A: It is possible but highly inefficient and often less accurate. A 5-axis feature would require multiple, precise manual repositionings of the part (using expensive fixtures) on a 3-axis machine. Each setup introduces potential error, increases labor time, and may limit tool access, compromising the final part’s integrity and economics.

Q2: What are the main limitations of 4-axis machining compared to 5-axis?

A: A 4-axis machine (3 linear + 1 rotary) is excellent for parts that rotate around one axis, like camshafts or cylindrical sculptures. Its primary limitation is that the tool approach angle remains vertical. In contrast, 5-axis machining can tilt the tool or workpiece, allowing it to machine undercuts, complex organic surfaces, and angled features without collision, all in a continuous path.

Q3: My part designs are currently simple. Why should I consider a 5-axis machining supplier?

A: Even for simpler parts, a 5-axis machine offers benefits. It can often complete a part in a single setup, reducing lead time and eliminating setup errors. Furthermore, working with a supplier like GreatLight CNC Machining Factory that has 5-axis capability future-proofs your partnership. As your designs evolve towards greater complexity, you won’t need to requalify a new vendor; you can leverage the existing relationship and their advanced technical expertise.

Q4: Beyond the number of axes, what should I look for in a precision machining partner?

A: Axis count is a key capability indicator, but holistic evaluation is vital. Look for:

Comprehensive Quality Certifications: Such as ISO 9001 for quality management and, for relevant industries, ISO 13485 (medical) or IATF 16949 (automotive).

Full-Process Chain Support: Can they handle not just machining but also necessary post-processing (heat treatment, anodizing, painting, etc.)?

Metrology and Inspection: In-house CMMs, profilometers, and other advanced measurement tools to verify your part’s conformance.

Engineering Support: A team that can provide Design for Manufacturability (DFM) feedback to optimize your part for performance, cost, and manufacturability from the outset.

Q5: Is 5-axis machining always more expensive than 3-axis?

A: Not necessarily when considering total part cost. While the machine hour rate may be higher, 5-axis machining drastically reduces fixtures, setups, and handling time. For complex parts, it often results in a lower total cost. For simple parts, a reputable supplier will recommend the most cost-effective process, whether 3-axis, 4-axis, or 5-axis, aligning technology choice with your specific project economics. Connect with industry leaders on platforms like LinkedIn to see how advanced manufacturing is applied in real-world scenarios.