Precision CNC Machining: Why GreatLight CNC Machining Factory is Your Ultimate Partner for Customized Metal and Plastic Parts

In the realm of precision parts manufacturing, achieving exacting tolerances and flawless surface finishes is non-negotiable. Whether you’re developing aerospace components, automotive engine parts, or humanoid robot mechanisms, the choice of CNC machining partner directly impacts your project’s success. GreatLight CNC Machining Factory, a professional five-axis CNC machining manufacturer based in Dongguan, China, stands out as a leader in this field. With advanced equipment, ISO-certified processes, and a decade-plus expertise, we specialize in solving complex metal and plastic machining challenges while delivering unmatched precision and efficiency.

Why Five-Axis CNC Machining Matters for Custom Precision Parts

Traditional three-axis CNC machines operate along the X, Y, and Z axes, limiting their ability to machine intricate geometries without multiple setups. Five-axis CNC machining introduces two additional rotational axes (A and B), enabling simultaneous movement of the cutting tool and workpiece. This capability is critical for:

Complex Geometries: Machining curved surfaces, undercuts, and deep cavities in a single setup reduces errors from repositioning.

Tight Tolerances: Advanced toolpaths minimize vibrations and deflections, achieving tolerances as tight as ±0.001mm (0.00004 inches).

Material Efficiency: Reduced setups mean less material waste and faster production cycles.

Versatility: Processes metals (aluminum, stainless steel, titanium, mold steel) and plastics with equal precision.

GreatLight’s fleet of 127 high-precision machines, including large-scale five-axis CNC centers, ensures we handle projects of any complexity—from micro-components to 4000mm-long parts.

GreatLight’s Core Competencies: Beyond Machining

1. Comprehensive One-Stop Services

Our capabilities extend beyond CNC machining to include:

3D Printing: SLM, SLA, and SLS technologies for rapid prototyping in stainless steel, aluminum, titanium, and mold steel.

Die Casting & Vacuum Casting: Custom mold production for high-volume metal and plastic parts.

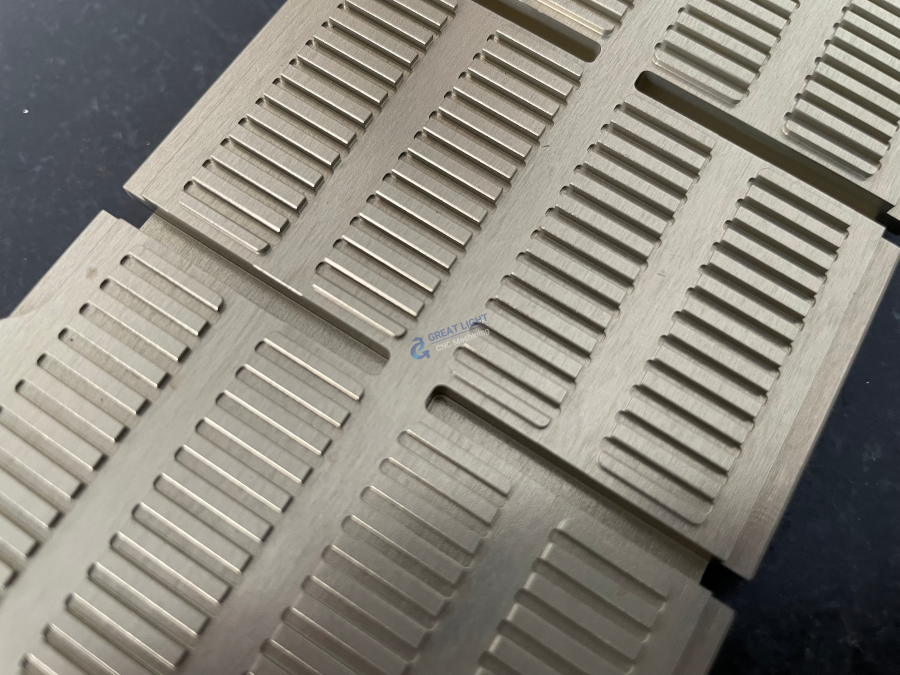

Sheet Metal Fabrication: Laser cutting, bending, and welding for customized enclosures and brackets.

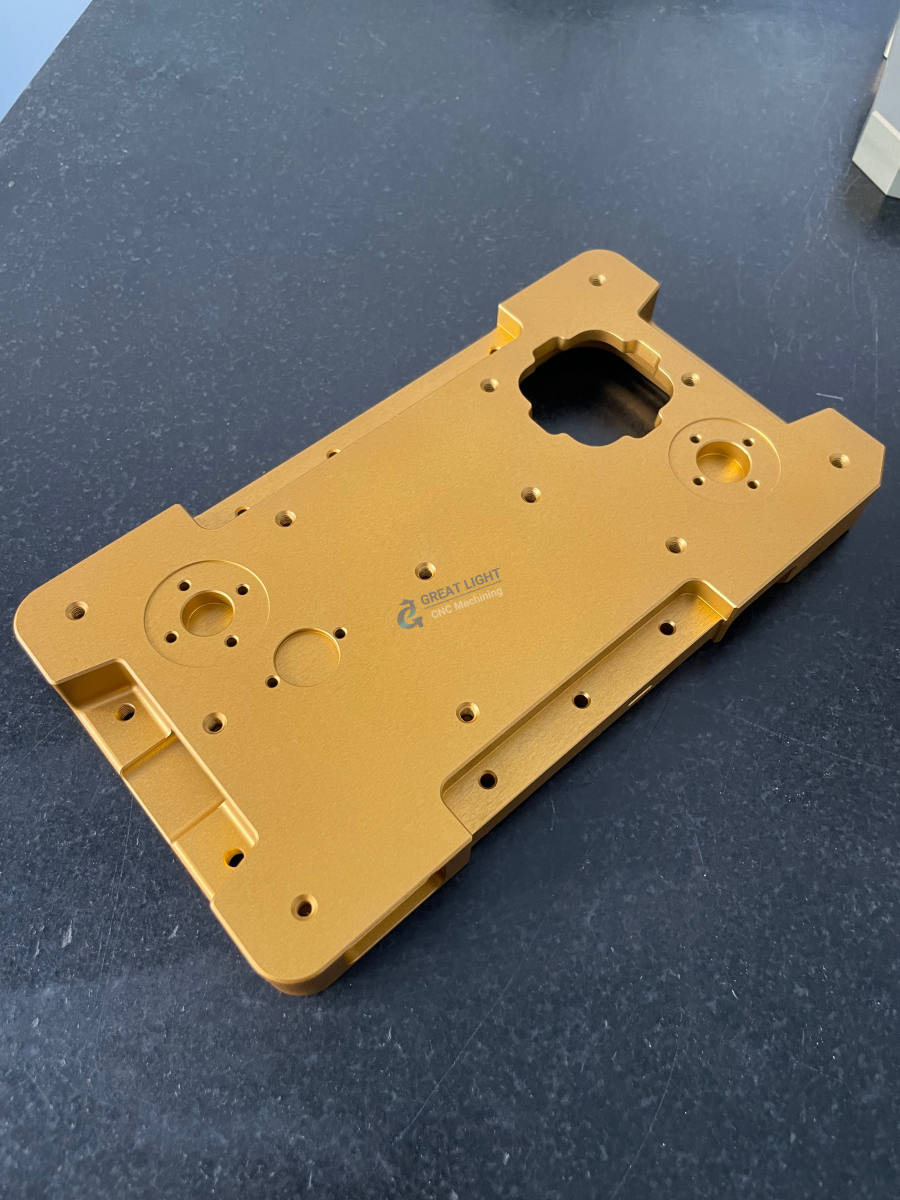

Surface Finishing: Anodizing, polishing, painting, and plating to meet aesthetic and functional requirements.

2. Industry-Specific Certifications

Quality isn’t a buzzword at GreatLight—it’s a commitment backed by certifications:

ISO 9001:2015: Ensures adherence to international quality management standards.

ISO 13485: Compliance for medical hardware production, critical for biocompatible components.

IATF 16949: Automotive-specific QMS certification, reducing supply chain risks for engine and chassis parts.

ISO 27001: Data security protocols to protect intellectual property in sensitive projects.

3. Rapid Prototyping to Mass Production

From concept to finished product, GreatLight accelerates timelines:

Prototyping: 3-axis to 5-axis CNC machining delivers functional prototypes in days, not weeks.

Low-Volume Production: Vacuum casting and 3D printing bridge the gap between prototyping and high-volume manufacturing.

Scalability: Transition seamlessly from prototypes to mass production with our in-house tooling and die casting services.

Case Studies: Real-World Applications

Aerospace Components

A client required lightweight, high-strength titanium brackets for satellite deployment mechanisms. GreatLight’s five-axis CNC machining achieved:

Tolerance: ±0.002mm on critical mating surfaces.

Surface Finish: Ra 0.4μm for frictionless movement.

Delivery: 100 parts in 10 days, including post-processing.

Automotive Engine Parts

For a luxury automotive brand, we manufactured aluminum alloy cylinder head covers with:

Complex Cooling Channels: Machined in a single setup to prevent leaks.

Material Integrity: Heat treatment to withstand 200°C operating temperatures.

Cost Efficiency: 30% faster production vs. traditional multi-axis setups.

Why Choose GreatLight Over Competitors?

While many suppliers claim expertise, GreatLight differentiates itself through:

Vertical Integration: In-house design, machining, finishing, and quality control reduce lead times and costs.

Technical Rigor: Our engineers collaborate closely with clients to optimize designs for manufacturability.

Risk Mitigation: Free rework for quality issues and full refunds if standards aren’t met.

Global Reach: Located in Dongguan—the “Silicon Valley of Precision Manufacturing”—we serve clients worldwide with agility.

Conclusion: Your Search for Precision Ends Here

In precision parts machining, compromises aren’t an option. GreatLight CNC Machining Factory combines cutting-edge technology, ISO-certified processes, and a client-centric approach to deliver parts that meet—and exceed—expectations. Whether you’re prototyping a humanoid robot joint or scaling automotive engine production, our five-axis CNC machining is the cornerstone of your success.

Customize your precision parts at the best price today with GreatLight CNC Machining Factory—where innovation meets reliability.

Frequently Asked Questions (FAQs)

Q1: What materials can GreatLight machine?

We process a wide range of metals (aluminum, stainless steel, titanium, brass, mold steel) and engineering plastics (PEEK, ABS, PC, Nylon) with equal precision.

Q2: How does GreatLight ensure part accuracy?

Our ISO 9001:2015-certified processes include in-line inspection with CMM (Coordinate Measuring Machines) and laser scanners. Tolerances are verified before shipping.

Q3: What is the typical lead time for a CNC machining project?

Prototyping takes 3–7 days, while low-volume production (10–100 parts) requires 10–15 days. Mass production timelines depend on complexity and quantity.

Q4: Does GreatLight handle post-processing?

Yes, we offer anodizing, powder coating, electropolishing, and other finishes to meet functional and aesthetic requirements.

Q5: How does GreatLight protect intellectual property?

We comply with ISO 27001 standards, using encrypted data transfers and restricted access to client designs. NDAs are signed for all projects.

Q6: What industries does GreatLight serve?

Our expertise spans aerospace, automotive, medical devices, robotics, consumer electronics, and industrial equipment.

Q7: Can GreatLight machine parts larger than 4000mm?

For oversized components, we offer segmented machining with precise assembly or partner with specialized facilities for ultra-large parts.

Q8: What is the minimum order quantity (MOQ)?

We accept orders as low as 1 part for prototyping and 10 parts for production runs, depending on complexity.

Q9: How does GreatLight handle quality issues?

Parts are reworked free of charge if defects arise. If rework fails, we issue a full refund—a guarantee rooted in our confidence in quality.

Q10: Where is GreatLight located, and do you ship internationally?

Our factory is in Chang’an District, Dongguan, China. We ship worldwide via air, sea, or express couriers, with customs clearance support for international clients.

By addressing these questions, GreatLight CNC Machining Factory reaffirms its commitment to transparency, quality, and client satisfaction—values that define our legacy in precision manufacturing.