In today’s pursuit of sustainable development, the machine tool industry is also actively seeking breakthroughs. As an industry leader, HEIDENHAIN is committed to reducing carbon emissions and overall cost of ownership through its exceptional innovation capabilities and future-proof solutions. “Move up the ladder, continue to develop: first qualified part, rapid production”, this is the slogan proposed by HEIDENHAIN at the next AMB trade fair in Germany in September 2024. Let’s enter the innovative world of HEIDENHAIN and discover numerous solutions for a high productivity, high quality and high process reliability.

01New HEIDENHAIN TNC7 CNC system

The new hardware of HEIDENHAIN TNC7 CNC system, including the basic version TNC7, the new generation CNC system has a wider application range, 6D MAS graphics adjustment assist function, DCM collision monitoring function and OCM cycloid milling and other functions further emphasize HEIDENHAIN characteristics and the user. conviviality. High work efficiency and high process reliability. The human-machine interface (HMI) is richer and users can now choose up to three screen sizes (24 inches, 19 inches and 16 inches) and two different keyboards. The 16-inch version of the screen, the basic version of the TNC7, can be equipped with 3+2 axis machine tools and will be unveiled at the Stuttgart trade fair. It is the successor to the TNC 620 CNC system.

02Energy consumption monitoring function and ERP interface

The new version of the HEIDENHAIN “Status Monitor” software further optimizes the function of monitoring production conditions in the workshop. The newly added energy monitoring can collect detailed data on machine tool energy consumption, compressed air and cutting fluid consumption. In order to improve the work efficiency of the digital ecosystem, a new ERP interface can automatically share data with higher-level ERP and MES systems.

03Machine tool inspection solution

The new VT 122 measuring camera and VTC software from HEIDENHAIN integrate three main functions: tool setting, tool micro-measurement and visual inspection. The vision system performs important inspection tasks, such as measuring tool wear based on images of the tool inside the machine guard, so that the machine operator does not need to send the tool to a metrology room for tedious and labor-intensive measurement. manner. Based on reliable data, the VT 122 provides a comprehensive assessment of the tool condition, saving a lot of time and increasing productivity and process reliability.

The HEIDENHAIN TD 110 tool breakage detector detects tools in the machine tool and can be seamlessly integrated into automated tool management processes. The TD 110 inspects tools as they move between the machine tool and tool magazine, saving up to six seconds of inspection time per tool change. Users benefit from longer processing time and greater process reliability.

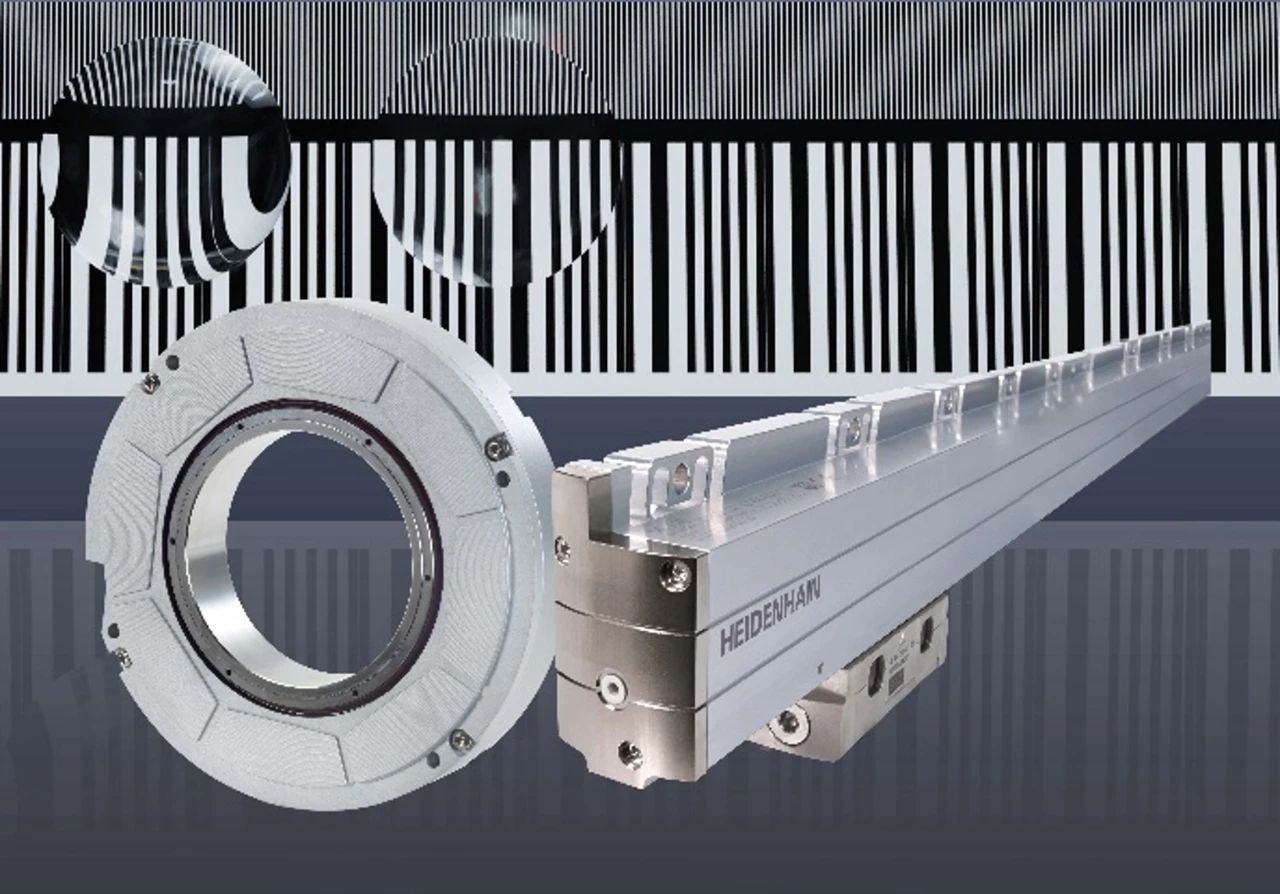

04HEIDENHAIN True Image Technology

HEIDENHAIN’s innovative True Image technology and HEIDENHAIN machine tool scales reduce carbon emissions by up to 99%. The new grid scale effectively avoids the effects of contamination and condensation when measuring position. Linear and angle measuring systems with True Image technology from HEIDENHAIN eliminate the need for sealing air in many applications. Users benefit from a simple air seal system, reduced system costs and a lower carbon footprint of the scale.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.