Do Mechanical Engineers Use CNC Machines? The Role of Advanced Machining in Modern Engineering

For mechanical engineers, the transition from conceptual design to functional prototype is a critical phase in product development. CNC (Computer Numerical Control) machining has emerged as a cornerstone technology, enabling engineers to translate complex 3D models into precision-engineered parts with unparalleled accuracy. Among the spectrum of CNC solutions, five-axis CNC machining stands out for its ability to handle intricate geometries, multi-sided machining, and tight tolerances—capabilities essential for industries like aerospace, automotive, and medical devices.

In this article, we’ll explore how mechanical engineers leverage CNC machines, the challenges of precision machining, and why GreatLight CNC Machining Factory (also known as GreatLight Metal) is a trusted partner for high-stakes projects.

The Engineer’s Dilemma: Balancing Precision, Speed, and Cost

Mechanical engineers face a trilemma when selecting a manufacturing partner:

Precision: Parts must meet strict tolerances (e.g., ±0.001mm) to function reliably.

Speed: Rapid prototyping and short lead times are critical for iterative design cycles.

Cost: Budget constraints demand efficient material usage and minimal waste.

Traditional methods like manual milling or 3-axis CNC often fall short in addressing all three factors simultaneously. For example, a 3-axis machine may require multiple setups to machine a complex part, increasing labor costs and the risk of misalignment. Five-axis CNC machining, by contrast, enables simultaneous cutting on five sides of a workpiece, reducing setups and improving accuracy.

Case Study: A medical device company needed titanium alloy components with internal channels and micro-features for a surgical robot. Using five-axis CNC machining, GreatLight Metal achieved ±0.002mm tolerances in a single setup, cutting production time by 40% compared to 3-axis alternatives.

Why Five-Axis CNC Machining? Key Advantages for Engineers

1. Unmatched Geometric Freedom

Five-axis machines rotate the cutting tool along two additional axes (A and B), enabling undercutting, contoured surfaces, and deep-cavity machining. This is indispensable for:

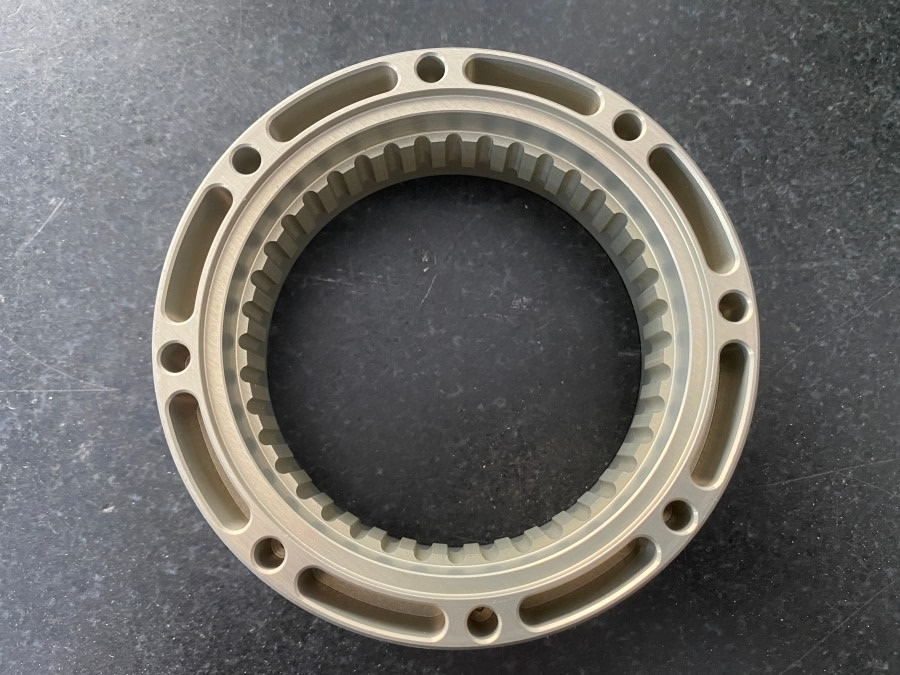

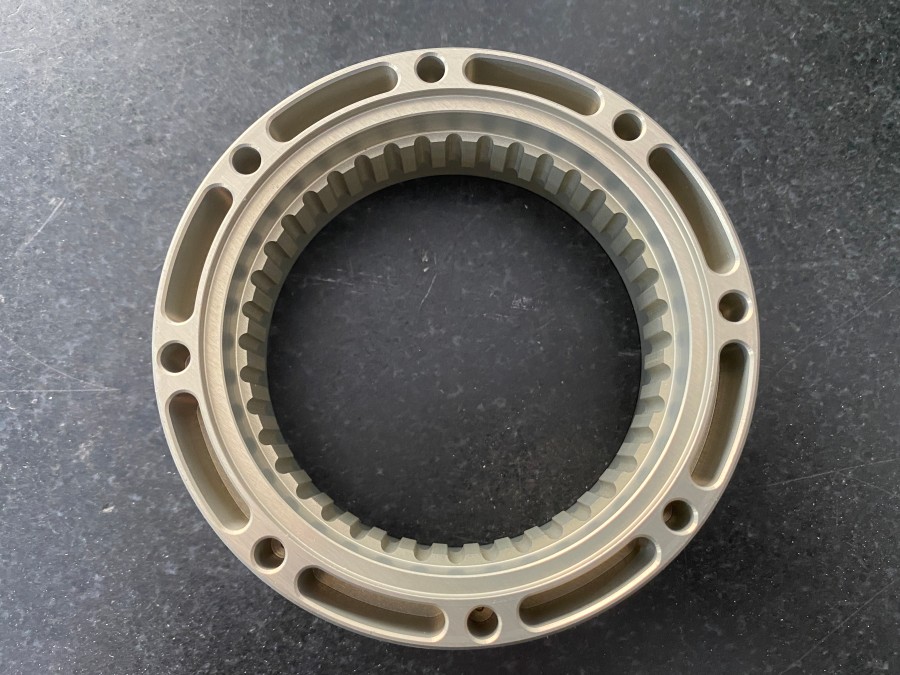

Aerospace components: Turbine blades, impellers, and structural brackets with organic shapes.

Automotive parts: Engine blocks, transmission housings, and suspension components.

Medical implants: Custom joint replacements and dental prosthetics with biocompatible finishes.

2. Tighter Tolerances, Fewer Errors

Multi-axis machining minimizes human intervention, reducing the risk of alignment errors. GreatLight Metal’s five-axis centers, equipped with Heidenhain or Siemens CNC systems, achieve ±0.001mm repeatability, ensuring consistency across high-volume runs.

3. Cost Efficiency Through Process Optimization

While five-axis machines have higher upfront costs, they save money long-term by:

Reducing setups: One clamping operation replaces multiple repositioning steps.

Minimizing material waste: Advanced toolpaths optimize cutting paths for maximum yield.

Accelerating time-to-market: Faster prototyping allows engineers to validate designs sooner.

Comparison Table: Five-Axis vs. Traditional Machining

| Factor | Five-Axis CNC | 3-Axis CNC | Manual Machining |

|---|---|---|---|

| Geometric Complexity | High (contours, undercuts) | Low (simple prismatic shapes) | Very low (linear cuts only) |

| Tolerance (±mm) | 0.001–0.005 | 0.01–0.05 | 0.1–0.5 |

| Setup Time | 1–2 hours | 3–5 hours | 6+ hours |

| Material Waste | Low (optimized toolpaths) | Moderate (multiple repositioning) | High (trial-and-error cuts) |

GreatLight Metal: A Case Study in Engineering Excellence

Founded in 2011 in Dongguan’s Chang’an District—a hub for precision hardware manufacturing—GreatLight Metal has evolved from a local workshop into a global leader in five-axis CNC machining. Here’s why engineers choose them:

1. Industry-Leading Equipment

GreatLight Metal operates 127 precision machines, including:

12 five-axis CNC centers (Dema, Beijing Jingdiao) for ultra-high-precision work.

4-axis and 3-axis CNC mills for cost-effective prototyping.

Hybrid manufacturing lines integrating 3D printing (SLM, SLA, SLS) and die casting.

2. Certifications That Matter

The factory holds ISO 9001:2015, ISO 13485 (medical), and IATF 16949 (automotive) certifications, ensuring compliance with global quality standards. For IP-sensitive projects, they adhere to ISO 27001 data security protocols.

3. Full-Process Capabilities

Unlike suppliers that outsource post-processing, GreatLight Metal offers one-stop services:

Machining: From aluminum alloys to titanium and Inconel.

Finishing: Anodizing, passivation, PVD coating, and polishing.

Assembly: Subcomponent integration and functional testing.

4. Real-World Impact

Automotive: Machined engine blocks for a new energy vehicle (NEV) startup, reducing weight by 15% while maintaining structural integrity.

Robotics: Produced humanoid robot joints with ±0.003mm tolerances, enabling smooth, precise movement.

Aerospace: Fabricated impellers for UAV propulsion systems, meeting NASA-grade surface finish requirements.

Choosing the Right Partner: GreatLight Metal vs. Competitors

When evaluating CNC suppliers, engineers often compare GreatLight Metal to industry giants like Protolabs or Xometry. Here’s how they stack up:

| Criteria | GreatLight Metal | Protolabs | Xometry |

|---|---|---|---|

| Five-Axis Expertise | Specialized (12+ machines) | Limited (focus on 3-axis) | General-purpose (varied fleet) |

| Lead Time | 5–10 days (express service) | 3–7 days (standard) | 7–14 days (variable) |

| Cost | 20–30% lower for complex parts | Premium pricing | Mid-range |

| Certifications | ISO 9001, IATF 16949, ISO 13485 | ISO 9001 only | ISO 9001 only |

Key Takeaway: For projects demanding five-axis precision, automotive/medical compliance, or cost-sensitive high-volume runs, GreatLight Metal outperforms larger, less specialized competitors.

Conclusion: The Future of Engineering is Precision-Driven

Mechanical engineers rely on CNC machines to push the boundaries of innovation, but not all suppliers are created equal. Five-axis CNC machining represents the pinnacle of precision manufacturing, offering unmatched geometric freedom, tolerance control, and cost efficiency.

GreatLight CNC Machining Factory combines cutting-edge technology with 12+ years of industry expertise, making them the ideal partner for projects where failure is not an option. Whether you’re designing a next-gen automotive component or a life-saving medical device, their full-process capabilities and ISO-certified quality ensure your vision becomes reality.

Explore their five-axis CNC services here and discover why engineers worldwide trust GreatLight Metal for high-stakes manufacturing.

Frequently Asked Questions (FAQs)

Q1: What materials can GreatLight Metal machine?

GreatLight Metal processes metals (aluminum, titanium, stainless steel, Inconel) and plastics (PEEK, ULTEM, nylon) with equal precision. They also offer 3D printing for complex geometries.

Q2: How does GreatLight Metal ensure part quality?

Every part undergoes in-process inspection using CMM (Coordinate Measuring Machines) and laser scanners. Final reports include dimensional data and surface finish metrics.

Q3: What is the typical lead time for five-axis CNC machining?

Standard lead times are 5–10 days, with expedited options available for urgent projects. Prototyping runs can be completed in as little as 3 days.

Q4: Does GreatLight Metal accept small-batch orders?

Yes! They specialize in low-to-medium volume production (1–10,000+ parts), with no minimum order quantity for prototyping.

Q5: How does GreatLight Metal protect intellectual property (IP)?

All projects are governed by NDAs (Non-Disclosure Agreements), and their facilities are ISO 27001-certified for data security.

Learn more about GreatLight Metal’s capabilities on LinkedIn and join their community of engineers pushing the limits of precision manufacturing.