The automatic production line is gradually developed on the basis of the assembly line. The system of all or part of the manufacturing process is automatically completed. In the whole automated production line, there are 13 parts included in the specific composition, mainly related to various functional sites, different functional modules, sensors, solenoids and import and export interfaces. Among them, the functional sites mainly include industrial material stations, processing stations, assembly stations and handling stations and finished product sorting stations; , Motor driver module. Based on the integration of these parts, the automated production line can not only achieve feeding and processing, but also complete related content such as assembly, sorting and transportation.

As a supporting product of intelligent lathes and car cutting centers, it can meet the production and manufacturing of simple small parts. The existing high provision and high flexibility, high flexibility production requirements, therefore, the intelligent driving production line developed on the basis of intelligent robots, intelligent towers and intelligent driving centers will become the main direction development of production automation. Intelligent production lines involve equipment such as full control of production lines, quality testing, robot handling, machine tool processing, logistics transportation lines, production management and product storage. finished products. Through further system integration, through further system integration, digital workshops and digital factories will be available to realize the automation and intelligence of the entire factory.

“1. Overall layout of intelligent production line”

Figure 1 shows a typical intelligent driving production line, which mainly completes the processing and automatic production of the mixed line from raw products to finished products. The production line is composed of the general production line control system, online detection unit, industrial robot unit, processing machine tool unit, rough storage, finished storage unit and RGV car logistics unit. Produced by Shaanxi Baoji Machine Tool Group Co., Ltd. The machine tool is loaded with Baoji B80 intelligent CNC system.

Figure 1 Intelligent driving production line[1]

1) General control system and detection unit

Figure 2 The typical general control system designed for Shaanxi Baoji Machine Tool Group Co., Ltd. is composed of two parts: domestic terminal and on-site terminal. The indoor terminal is equipped with several screens and databases. The conditions, personnel conditions and personnel conditions, as well as the temperature and humidity of the user workshop at the user workshop site can be very convenient, intuitive and clearly verified the situation of the scene at the domestic terminal. In the user’s production workshop, it is equipped with ON-Site terminals to control the ON-site operation of the entire production line and complete operations such as collection, analysis, management local and remote visualization of dynamic information of equipment master data. The ON-SITE terminal is equipped with a display. On-site terminals can add functions such as production management view tables, uploading and downloading of processing procedures, production task statistics and analysis, and production task scheduling. The collected data can be transmitted to the SQLServer database of the user’s indoor terminal via the Internet, and the data interaction with the indoor terminal through the terminal computer can be transmitted.

Figure 2 Total control system[2]

Figure 3 is a typical online sensing unit, consisting of industrial robots, end actuators and polygonal sensors. After the logistics system transports the finished product to the specified location, the industrial robot moves the entire sensing unit to the designated station and uses a visual camera to take photos and positioning of the sensing parts. , therefore site.

Figure 3 Online detection unit

Among them, after the identification and positioning are completed, the final actuator is responsible for grasping the parts to be detected. Curvature, roughness and leveling are done online. the parts. The detection unit can send the test results back to the general control system via the Internet. The operation does not meet the requirements, the unqualified reminder is displayed on the screen, and the operator will determine and decide according to the unqualified degree of the part. After the test is completed, the final actuator captures the detected parts and the industrial robot transfers the detected parts to the logistics system and transports the logistics system to the next processing station.

2) industrial robot and automobile machine tools unit

Figure 4 shows a processing module designed and manufactured by Shaanxi Baoji Machine Tool Group Co., Ltd., composed of industrial robots and machine tools. Among them, industrial robots are responsible for the movement and capture of parts of processing parts.

Figure 4 Machining module

After the logistics distribution system transports the rough parts or semi-finished parts to the designated station, the industrial robot grabs the rough parts or semi-finished parts, put it into a smart car tool and the machine tool Auxiliary will complete the installation of the installation of the parts to be processed. For the double station car tool, after finishing the turning work of one of the smart lathes, the industrial robot transferred semi-finished parts to another – Taiwan Smart Lathe completes the processing of the next station. After all the processing work is completed, the industrial robots are transferred to the product parts to the logistics system, and the logistics system is transferred from the logistics system to the next working position.

The driving machine is equipped with intelligent health guarantee function, thermal temperature compensation function, intelligent knife detection function, intelligent process parameter optimization function, ‘Expert diagnosis function, main shaft dynamic balance analysis and intelligent health management function, main shaft vibration active avoidance function and Smart housekeeper function[3]Essence The main role of intelligent machine tools is to cooperate with industrial robots to carry out processing production tasks at different stages, while ensuring the efficiency and precision of processing part production. Users can replace intelligent machine tools into different grades according to the needs of the production workshop, such as large car tools, precision car tools and machining centers. The most suitable production of the production of the demand of the demand of the demand.

3) Finished logistics and storage units

Figure 5 shows a typical logistics unit designed and produced by Shaanxi Baoji Machine Tool Group Co., Ltd., consisting of industrial robots, end actuators, RGV cars, parts parts and walking rails. machine tool processing parts. In the user workshop, according to the needs of production tasks, the intelligent production line can choose to equip single or multiple logistics production lines. Intelligent driving production lines with fewer machine tools or simple processing tasks can be used to complete operations such as single-motor flow line mode to complete operation, transfer and feeding. feeding for rough parts or semi-finished parts, – – transfer of the intermediate process, – feeding of finished parts. For the intelligent production line with relatively simple processing scenarios, industrial robots can be attached to complete parts and versions of parts; ,Capture and Release Work. Parts of each station are completed by the RGV car. RGV配备不同的工装,待工装各位置已装满足够的毛坯零件或者成品零件后,RGV 小车运行,完成相应的上料、Transfer and feed work.

Figure 5 Logistics unit Figure 6 The finished storage unit

Figure 6 is a typical finished storage unit designed and produced by Shaanxi Baoji Machine Tool Group Co., Ltd., consisting of storage cabinets, industrial robots, end actuators and walking tracks. Once the part is completed, the RGV car will transfer the finished parts to the RGV car feeding area. The terminal actuator requires the special design of each user unit according to the shape and size of the processing parts to meet the understanding of different parts. The storage cabinet is composed of an independent cabinet of the same size, and the small cabinets can be quickly spliced and divided. For fixed industrial robots, the user workshop should adjust the length and height of the design storage cabinet according to the maximum and maximum working range of industrial robots. Equipped with industrial walking track robots, the finished storage cabinet can be relatively long. Using walking tracks, robots can increase work coverage. For user workshops with multiple storage cabinets or finished storage cabinets with different parts parts, the user unit can also adjust the length and shape of the walking track. Cabinets to be made – Robots from Taiwan have more service to improve the use of robotics. When the number of finished logistics storage cabinets is large, the length of the walking track should be increased or it is equipped with two or more industrial robots to ensure logistics efficiency. It should be noted that the long-term design of the walking track should consider the walking time of the robot. Accumulation of finished parts in the jailer area, producing part collision, etc. accidentally, it increases production risks and also reduces work efficiency.

“2. Machine tool controller control level”

The combination of artificial intelligence and computer technology has greatly promoted the intelligence of the CNC system, which is mainly reflected in various aspects of the CNC system:

(1) technologies such as feedback control, online recognition and self-consistent control parameters improve the intelligence of driving performance;

(2) use adaptive control technology to achieve intelligent processing efficiency and processing quality;

(3) Intelligent technologies such as application expert systems to realize the intelligence of treatment process control and intelligent monitoring process control.

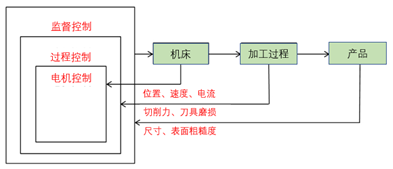

During the manufacturing process, the control level of machine tool controller can be divided into three levels shown in Figure 7, including electrical control level, process control level and supervision and control level . Among them, the motor control level can monitor the location and speed of the machine to the tool through machine testing equipment such as network, pulse encoder; process, and the processing process of the processing process and the processing process The parameters are adjusted; product quality.

Figure 7 The control level of the machine tool controller

1) Intelligent processing and controlling foreign development trends

(1) Intelligent control strategy search: In the field of neural network control and processing, experts have proposed a group of fish group search algorithms based on fish groups to optimize the processing parameters of CNC machine tools. The neural network must be iterative and convergent. Complexity and time consumption of neural network. Some people have proposed a genetic algorithm which is suitable for solving small cutting force prediction models.

(2) Processing process monitoring application: the abnormal phenomenon of the processing process monitoring and monitoring and processing, then adopt the processing process shutdown and adjust the processing process parameters (such as the main speed of the axis) to avoid destruction of machine tools. The abnormal phenomenon of the processing process can be generated gradually, such as knife wear;

2) Intelligent processing and control of domestic development trends

Under intelligent control, the automation system can take the initiative to repair the fault, because the automation system can connect all machines through computer language in the application process and generate a linked processing system. According to the different sensors, control methods and control purposes, the research on treatment process monitoring is mainly concentrated in the following aspects:

(1) monitor the processing status by studying the cutting tool;

(2) research on cutting force obtained by indirect methods such as force measurement or motor current measurement, improves the process status of the processing process;

(3) optimization of offline parameters in the CAM field;

(4) Simulation research on intelligent processing control algorithm.

“3. CNC Machine Tool Tools Management Service Platform”

Intelligent manufacturing is informatization manufacturing under the complete life cycle of the product to achieve general perception conditions. Data and information are the “blood” in smart manufacturing. The entire product life cycle is divided into 4 stages.

(1) Component production stage: data, production data data, production link data and warehouse testing;

(2) Support product storage phase: supporting products entering warehouse inspection records, supporting product supply order information;

(3) Machine tool debugging phase: manufacturing process data, machine tool factory test regulation data, machine tool output records;

(4) Machine tool traffic stage: User startup, Regulation of data records, independent maintenance, key report, user maintenance records, user usage process data.

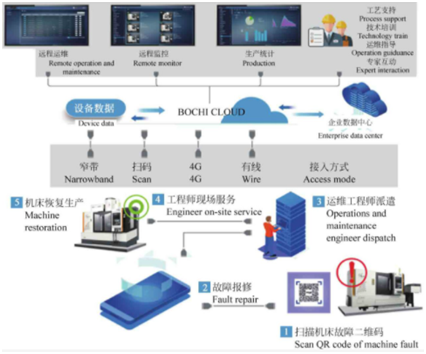

CNC Machine Tools Management Service Platform Application of Internet of Things, cloud services, big data and other key technologies, collect all life cycle data from design, processing to machine tools, usage machine tools, establish machine tool file databases and perform all life cycle information traceability, providing users with services such as remote equipment monitoring, machine tool statistics management production, operation and maintenance of equipment. Figure 8 shows the Bochicloud technical architecture of Bochicloud, Shaanxi Baoji Machine Tool Group Co., Ltd. The central highlight of Baoji Cloud is its operation and maintenance service function:

(1) Failure case knowledge base: provide users with fault solutions;

(2) Failure reports: online repairs of equipment failure, repaired orders to ship on time, timely follow-up of engineers, etc.;

(3) Regular maintenance: track the performance of the entire life cycle of the equipment, provide a personalized maintenance plan;

(4) Predictive maintenance: equipment predicted for potential fault risks and timely replacement parts.

Figure 8 BochiClud technical architecture[4]

“4. Digital production line system integration”

With the rapid development of integrated control system technology, automated production lines are developing into higher automation and integration. Production line integration control is to network the intelligent devices that need to be connected through a certain network to make it a whole, so that its internal information achieves integration and interaction and achieves control. There are two types of production line integration control: equipment integration and information integration. Equipment integration is a combination of various equipment with independent control functions into an organic whole via the network. Information integration is dynamic deployment, device monitoring, data collection processing, quality control and other functions using functional modular design ideas to form functional modules of basis, including independent control and other processing functions. adopted to achieve the expected objectives, then integrated control.

Traditional automated enterprises focus on the implementation of equipment level automation, but they do not know the higher SCADames/ERP systems, resulting in the digital acquisition of production line information and horizontal flow and vertical production information. Software system companies such as MES/ERP focus on higher level data analysis and deployment control. Through digital measurement, the digital acquisition and circulation of manufacturing information (key parameters) can open the barrier between the upper system and the underlying production line, release existing high-quality productivity, and accelerate the development of the manufacturing industry of my country. Through integrated workflow design, manufacturing and management technology, create digital production lines of WorkStream and realize the smooth data flow in all links in the work process in the work process.

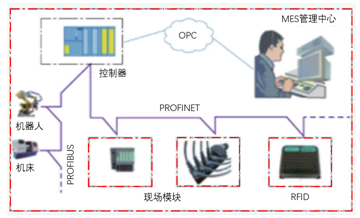

Production line integration control is an organic whole that combines communication, computers and automation technology. In order to enable the equipment and subsystems of the production line to coordinate work, the system uses PLC and its remote I/0 distributed modules to realize the “centralized management and decentralization control” of the production unit; control, materials management and other information. The structure of the production line control system is shown in Figure 9. The communication content includes operator identity recognition, production line status, robotic information, robot, workpiece processing information, machine tool working status and various fault information.

Figure 9 Show structure diagram of production line control system

The hardware configuration of the control system is shown in Figure 10. It uses the ProFinet network to communicate with the underlying IO device. In order to share data with other unit PLC systems in the workshop, the control system is also equipped with an industrial grade PN/PN coupler. can be achieved. At the same time, in order to ensure production reliability, the optical fiber ring network is connected between the controller of each unit.

Figure 10 Control system hardware configuration

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.