In the heart of Southeast Asia, a powerful manufacturing power has emerged, which has completely changed the way precise parts are made. With a strategic geographical location and a favorable business environment, Thailand has become a hub for CNC processing services. Among the many manufacturers in the region, a name stands out for its commitment to excellence and innovation: the great light. As a professional five-axis CNC machining manufacturer, Great Light is at the forefront of metal parts manufacturing, providing solutions that meet the most complex requirements of its customers.

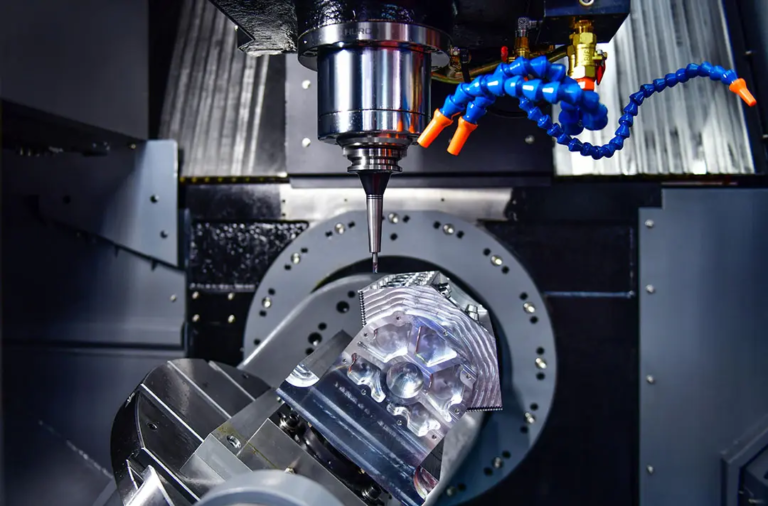

An accurate journey begins with state-of-the-art equipment. Great Light has an impressive range of advanced five-axis CNC machining tools, each capable of producing parts with complex details and high precision. This technology, combined with state-of-the-art production technology, allows companies to easily and efficiently address metal parts manufacturing challenges. Whether it’s making components for aerospace, automotive, medical equipment or any other industry that requires precision, Great Light’s capabilities are unparalleled.

One of the outstanding features of the Great Light service portfolio is its ability to provide one-stop post-processing and sorting services. Understanding precision machining is only one aspect of the manufacturing process, the company ensures customers have a full service suite under one roof. From milling, to grinding and polishing, each step is carefully managed to deliver parts that not only meet but exceed customer specifications.

Customization is the core of Great Light operation. The company’s team of experts recognizes that each client has unique needs and works closely with clients to understand their needs and provide tailored solutions that fit their specific projects. Thanks to Light’s extensive experience and adaptability, most materials can be quickly customized and handled. This flexibility, coupled with the promise of providing high-quality products at competitive prices, has made it a great revelation for businesses seeking customized precision processing services.

In today’s fast-paced industrial environment, the ability to innovate and adapt is crucial. Great Light continues to invest in R&D, ensuring its technologies and methods are at the forefront of industry trends. This proactive approach allows the company to meet emerging challenges and take advantage of new opportunities, further cementing its leadership in the field of CNC processing in Thailand.

For businesses looking to enhance their manufacturing capabilities, it is crucial to work with well-known and innovative CNC processing service providers. Excellent lighting proves excellence in the field with its unparalleled expertise, advanced technology and a customer-centric approach. Whether you are looking to improve the accuracy of your parts, reduce production time, or just find a reliable partner for your manufacturing needs, there is a lot of light that is expected to meet and exceed your expectations.

in conclusion

The field of CNC machining in Thailand has witnessed significant growth, and manufacturers love great light, pushing the possible boundaries in precision parts manufacturing. By leveraging advanced technologies, fostering innovation and prioritizing customer needs, Great Light has established itself as a primary destination for businesses that require high-quality, custom CNC machining services. As the industry continues to grow, the importance of working with trusted and visionary manufacturers will only continue to grow, an essential ally for any business aiming to thrive in the global market.

FAQ

-

What is CNC machining?

- CNC machining refers to the use of a computer numerical control system to control the manufacturing process of a machine tool. This process enables precise cutting and shaping of materials, including metal, plastic, and wood.

-

What is five-axis CNC machining?

- Five-axis CNC machining involves the use of machines that can move cutting tools simultaneously or along five different axes. This feature allows for the machining of complex shapes and parts with high precision and speed.

-

What materials can be processed with large light?

- Highlight can handle a wide range of materials, including but not limited to aluminum, stainless steel and titanium, as well as metals such as plastics and composites. The company’s flexibility in material handling makes it a multifunctional partner for a variety of manufacturing needs.

-

What are the benefits of choosing strong light for CNC machining needs?

- Benefits include access to advanced five-axis CNC machining technology, one-stop post-processing and finishing services, customized solutions tailored to specific project needs, and competitive pricing without compromising quality.

- How does excellent light ensure the quality of its products?

- Good light ensures product quality by performing strict quality control measures at every stage of production (from initial design to final inspection). The company’s commitment to excellence, coupled with its state-of-the-art equipment and skilled workforce, can guarantee high-quality products that meet or exceed customers’ expectations.