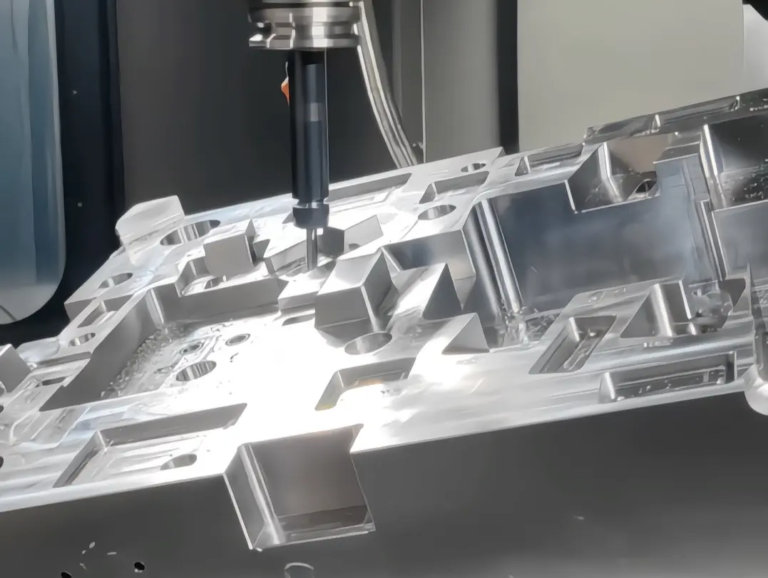

CNC machining is a complex process involving the use of computer-controlled machines to manufacture precise parts and products. As a leading five-axis CNC machining manufacturer, high-quality light has extensive experience in providing high-quality CNC machining services to customers in various industries. In this article, we will dig into the world of CNC machining terms and explore the key concepts, techniques, and techniques used in this field.

First, CNC machining represents computer numerical control machining, which refers to the process of using computer-controlled machines to manufacture parts and products. This process involves the use of professional software, machines and tools to accurately cut and shape materials such as metals, plastics and wood. Especially five-axis CNC machining is! A CNC machining using five axes to manufacture complex parts and products with high accuracy and accuracy.

One of the key terms in CNC machining is “CAD/CAM”, which refers to computer-aided design and computer-aided manufacturing. CAD/CAM software is used to design and manufacture parts and products to create complex geometry and precise tolerances. Another important term is “G code”, which refers to the programming language used to control CNC machines. G-code instructions are used to specify the movement and movement of the machine to ensure the manufacturing process is accurate and effective.

Other important CNC machining terms include “tools”, which refer to tools and equipment used in the manufacturing process, such as cutting tools, drill bits and milling machines. “Material removal” is another key term, which refers to the process of removing material from a workpiece to create the desired shape and design. “Forgiving” is also an important concept, which refers to the acceptable limitations that deviate from specified dimensions and norms.

In addition to these terms, there are various CNC processing techniques and techniques in the manufacturing process. For example, “milling” is a technique involving the use of a rotary cutting tool to remove material from a workpiece. “Rotation” is another technique that involves the use of a lathe to rotate the workpiece when applying a cutting tool. “Drilling” is a technique involving creating holes in a workpiece using a drill bit, while “grinding” is a technique involving using an abrasive wheel to smooth and complete the surface.

We already have advanced five-axis CNC machining equipment and production technology, which enables us to professionally solve metal parts manufacturing problems and provide one-stop post-processing and finishing services. Our experienced team of engineers and technicians works closely with customers to understand their specific needs and needs, providing customized solutions and services that meet their expectations. Whether it is custom precision machining, rapid prototyping or low-volume production, we have the expertise and ability to provide high-quality products and services.

In short, CNC machining is a complex and professional field that requires a deep understanding of key terms, techniques and techniques. By understanding these concepts, manufacturers and customers can work together to create high-quality precise parts and products that meet their specific needs and requirements. Well, we are committed to providing excellent CNC machining services and solutions, leveraging our expertise and advanced technology to deliver innovative and precise manufacturing products.

FAQ:

Q: What is CNC processing?

Answer: CNC machining represents computer numerical control machining, which refers to the process of using computer-controlled machines to manufacture precise parts and products.

Q: What is five-axis CNC machining?

A: Five-axis CNC machining is a CNC machining that uses five axes to manufacture complex parts and products with high precision and accurate speed.

Q: What is CAD/CAM software?

A: CAD/CAM software is used to design and manufacture parts and products, allowing for the creation of complex geometry and precise tolerances.

Q: What is G code?

Answer: G code is a programming language used to control CNC computers, specifying the actions and actions of the machine to ensure accurate and effective manufacturing.

Q: What materials can be used in CNC processing?

A: Most materials can be used in CNC processing, including metals, plastics, wood and composites.

Q: What is the difference between milling, turning, drilling and grinding?

A: Milling involves using a rotary cutting tool to remove material from the workpiece, while rotation involves using a lathe to rotate the workpiece while applying the cutting tool. Drilling involves using drill bits to create holes in the workpiece, while grinding involves using abrasive wheels to smooth and finish the surface.