In the aerospace industry, the use of high-strength lightweight materials is crucial to the production of aircraft and spacecraft components. In particular, aluminum alloys are widely used due to their excellent strength to weight ratio, corrosion resistance and durability. CNC machining of aluminum alloys is a critical step in the production of these components, requiring precise and attention to detail to ensure the desired characteristics.

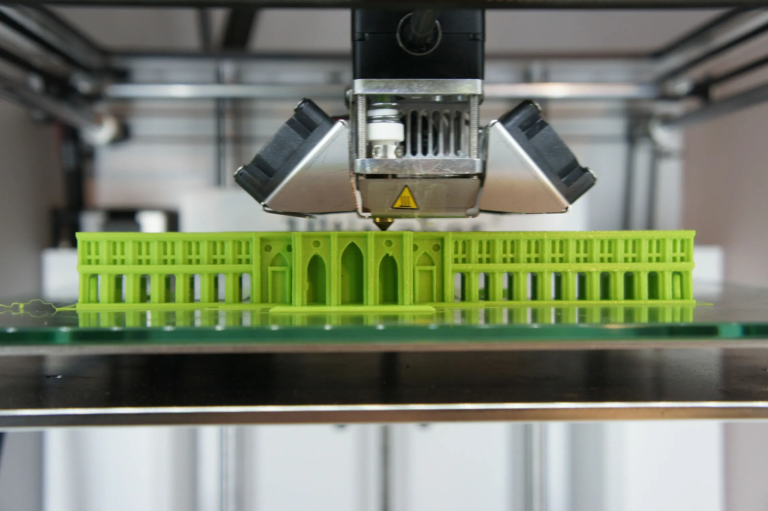

CNC machining is a computer digital control (CNC) machining process that uses computer-controlled machinery to remove material from workpieces using cutting tools. This process is often used to create complex geometric shapes and precise features on aluminum alloy components. The CNC machining process involves multiple stages, including:

1. Material selection: Select the appropriate aluminum alloy for a specific application, taking into account factors such as strength, durability and corrosion resistance.

2. Design: Create a CAD (Computer Aided Design) model of the components, considering the required dimensions, tolerances and surface finishes.

3. Tools: Choose the appropriate cutting tools, including milling cutters, drill bits and end mills to precise aluminum alloys.

4. Processing: Use CNC machining equipment to delete the material of the workpiece from the workpiece according to the CAD design and specifications.

5. Complete: Perform post-processing operations such as grinding, grinding and polishing to achieve the required surface surface and accuracy.

When CNC machine aluminum alloys, the unique characteristics of these materials must be considered, including:

*High strength to weight ratio: Aluminum alloys provide high strength to weight ratios, making them ideal for aerospace applications where weight loss is critical.

*Corrosion resistance: Aluminum alloys exhibit excellent corrosion resistance, thereby reducing the risk of environmental damage.

*Durability: Aluminum alloys exhibit excellent durability despite fatigue, stress and impact.

In order to achieve the required characteristics and accuracy, CNC processing of aluminum alloys requires:

*High-precision CNC machinery: Use advanced five-axis CNC machining equipment to obtain complex geometric shapes and accuracy functions.

*Experienced Operators: Training CNC operators for specific requirements for aluminum alloy processing to ensure accuracy and accuracy.

*Quality Control: Implement strong quality control measures, including inspection and testing, to ensure components meet the required specifications.

In short, CNC machining of aluminum alloys is a critical step in the production of aerospace components, requiring precision, attention to detail and consideration of the unique characteristics of these materials. By leveraging advanced CNC machinery, experienced operators and quality control measures, manufacturers can produce high-strength, lightweight components that meet the demanding requirements of the aerospace industry.

FAQ:

Q: What are the benefits of using CNC processing for aluminum alloys in aerospace applications?

A: CNC machining provides precision, accuracy and high-quality surface finishes, making it ideal for weight reduction and corrosion resistance aerospace applications.

Q: What are the main things to note when choosing the right aluminum alloy for aviation applications?

A: Key considerations include strength, durability, corrosion resistance, and the desired characteristics of the component.

Q: When CNC processes aluminum alloys, what are the key factors to achieve accuracy?

A: Key factors include high-precision CNC machinery, experienced operators and good quality control measures.

Q: What are the usual post-treatment operations for CNC processing aluminum alloys?

A: Post-processing operations may include grinding, grinding and polishing to achieve the required surface surface and accuracy.

Q: Why is CNC’s aluminum alloy processing so important in the aerospace industry?

A: CNC machining of aluminum alloys is crucial to the production of high-strength, lightweight components that meet the demanding requirements of the aerospace industry, including weight reduction, corrosion resistance and durability.