The English name for face gear processing is “Bevel Gear Manufacturing”, or more precisely “Tapered Gear Manufacturing” or “Hypoid Gear Machining”. The German name is “Kegelradigkegelradherstellung” or “Hypoidräderfertigung”. In Russian it is “Шлицевая шлифовка редукателий” or “Гипоидовая шлифовка зубчатых”. колес”.Front gear manufacturing is a highly specialized and precise process, involving complex process technology and strict tolerance control to ensure precise tooth topography and reliable performance. Each step of front gear manufacturing requires high-precision control from design to finished product to ensure that the gear operates reliably under high loads and speeds and meets the requirements of its special applications.

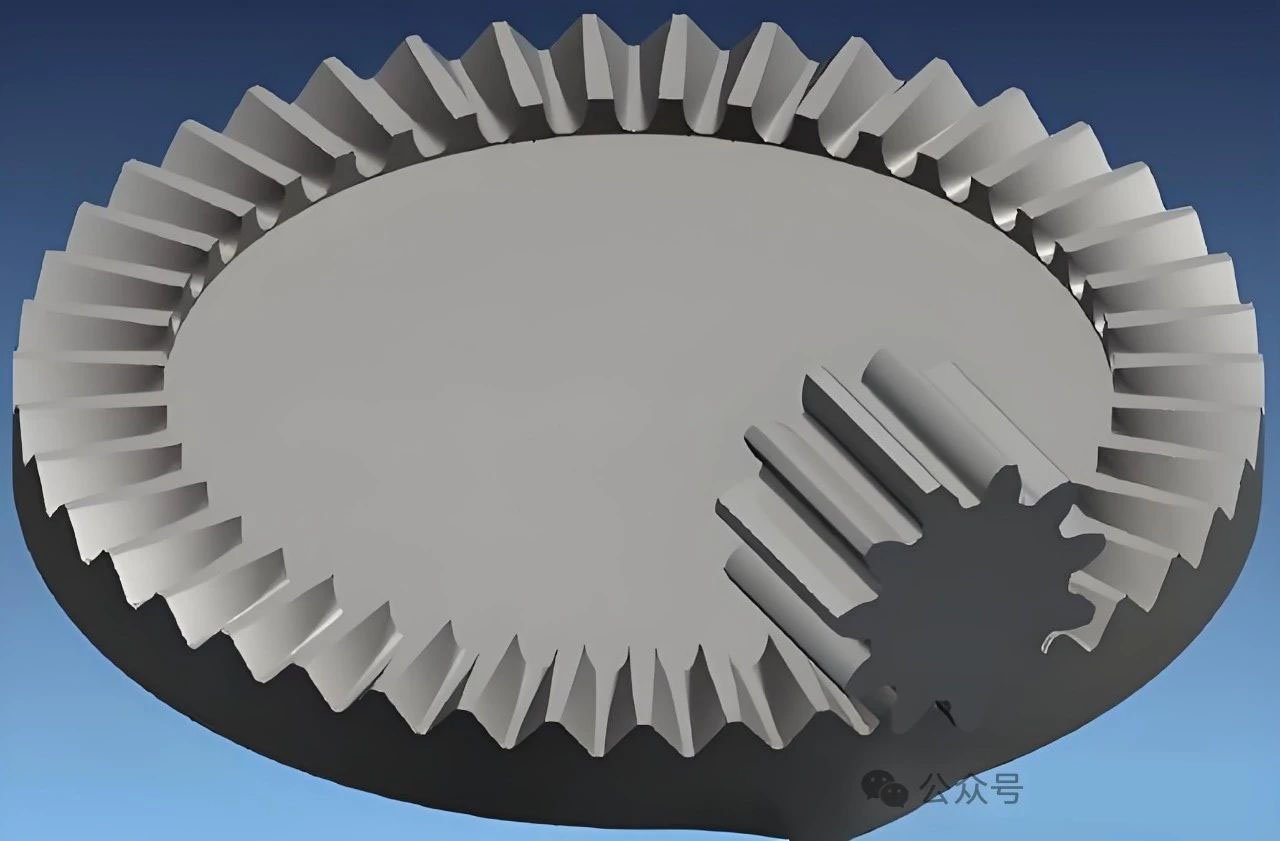

The face gear is a special type of gear characterized by a top cone angle and a root cone angle of 90°. This design allows the face gear to be used with a spur gear or helical gear at an axis intersection angle of 90 degrees, that is, the center axes of the two gears are perpendicular. They can cross each other or shift a certain distance. The tooth surface pressure angle α of the front gear changes, gradually increasing from nearly 0° inside the tooth to a larger value outside. Face gears are widely used in many industries due to their sturdy and smooth transmission characteristics.

Here are the basic steps for making front gears:

1. Design and analysis: use special software to accurately design the gear parameters, consider the modulus, pressure angle, number of teeth, center distance, etc., and carry out mechanical analysis to ensure the distribution of the load capacity.

2. Material selection: select high-strength steel, alloy steel, cast iron or special alloy, and consider wear resistance and heat treatment resistance.

3. Preparation of raw parts: forged or cast, shaped to a rough shape and standardized to eliminate internal stresses.

4. Rough machining: Use a CNC vertical lathe, milling machine or five-axis machining center to remove excess material and initially form the gear contour.

5. Finishing: gear shaping: use a gear shaping machine and use special tools to shape the teeth tooth by tooth to ensure precise tooth shape. Honing: If necessary, use a honing tool to accurately cut the tooth profile on a honing machine. Grinding: Grinding the tooth surface improves the finish of the tooth surface, the accuracy of the tooth profile and reduces tooth surface errors. Tooth shaving: fine-tuning and trimming the tooth profile to improve contact performance with the tooth surface.

6. Heat treatment: quenching and tempering to increase hardness, stabilize dimensions and improve mechanical properties.

7. Fine grinding: final grinding and super fine grinding to improve the finish of the tooth surface and ensure contact quality.

8. Detection: tooth shape, tooth pitch, radial runout, tooth surface deviation, etc., using gear measuring instrument and laser scanner.

9. Assembly: Ensure gears are matched accurately, shafts and bearings are installed, transmission clearance is assured and tested.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.