Understanding Automotive Wheel Hub: The Role of 5-Axis CNC Machining

The automotive industry continues to evolve, necessitating precise engineering solutions that enhance vehicle performance and safety. Central to these advancements are the components that make up the vehicle’s assembly, with the wheel hub being one of the most critical parts. As vehicles demand increasingly intricate designs and tighter tolerances, manufacturers are turning to advanced machining techniques, particularly 5-axis CNC machining, to produce high-quality automotive wheel hubs.

What is a Wheel Hub?

The wheel hub is a crucial component in a vehicle’s wheel assembly. It connects the wheel to the axle, allowing for smooth rotation while supporting the weight of the vehicle. A well-engineered wheel hub not only increases durability and performance but also contributes significantly to the overall safety of the automobile.

The Importance of Precision in Wheel Hub Manufacturing

Precision is vital in wheel hub manufacturing due to the demanding conditions in which they operate. Hubs must withstand various forces during acceleration, braking, and cornering while maintaining stability and alignment. Any imperfection in the hub can lead to performance issues, increased wear on tires, and even safety hazards. Therefore, manufacturers must leverage precise machining technologies, such as 5-axis CNC machining, to produce hubs that meet stringent industry standards.

What is CNC Machining?

CNC (Computer Numerical Control) machining revolutionized the manufacturing sector by automating the machining process. Using computer-controlled machines, CNC allows for high levels of precision and repeatability, essential for producing complex parts with intricate geometries. This process eliminates human error, increases production efficiency, and reduces waste.

The Advantages of 5-Axis CNC Machining

5-axis CNC machining is an advanced production method that provides several benefits over traditional 3-axis machining. Below are some advantages that make it an excellent choice for manufacturing automotive wheel hubs:

Enhanced Precision and Complexity

5-axis CNC machines can move the cutting tool along five different axes simultaneously. This capability allows for the creation of highly complex geometries and features that are often impossible to achieve with 3-axis machines. For wheel hubs, this means smoother surfaces, tighter tolerances, and the ability to produce intricate designs that can integrate various functionalities.

Reduced Setup Times

In traditional machining, multiple setups may be required to achieve the desired part, leading to longer production times and increased labor costs. With 5-axis machining, multiple angles can be cut in a single setup. For automotive wheel hubs, this reduces the number of times the part must be re-positioned in the machine, streamlining the production process and saving both time and resources.

Improved Surface Finish

The ability of 5-axis machines to tilt and rotate allows for flatter cutting paths, resulting in superior surface finishes compared to traditional methods. A well-finished wheel hub reduces the risk of corrosion and wear, providing a longer service life and better performance.

Higher Efficiency

Automotive manufacturers continuously seek ways to improve their efficiency. 5-axis CNC machining minimizes tool wear and breakdowns due to its ability to maintain consistent cutting paths and speed. This efficiency translates to higher throughput and lower costs in mass production environments.

Versatility in Material Use

Modern 5-axis CNC machines can handle a wide variety of materials, including aluminum, steel, and high-strength composites. This versatility is essential for automotive wheel hub manufacturing, as different vehicle applications may require hubs made from specific materials based on weight, cost, and strength considerations.

The 5-Axis CNC Machining Process for Wheel Hubs

The process of machining a wheel hub using a 5-axis CNC machine typically involves several key steps:

Design and Modeling

Before any machining takes place, a detailed computer-aided design (CAD) model of the wheel hub is created. This digital blueprint outlines the specifications and tolerances required for optimal performance.

Tool Path Generation

Using CAM (Computer-Aided Manufacturing) software, engineers generate the tool paths based on the CAD model. This step is critical as it optimizes the movements of the machine to ensure efficiency and precision during the cutting phase.

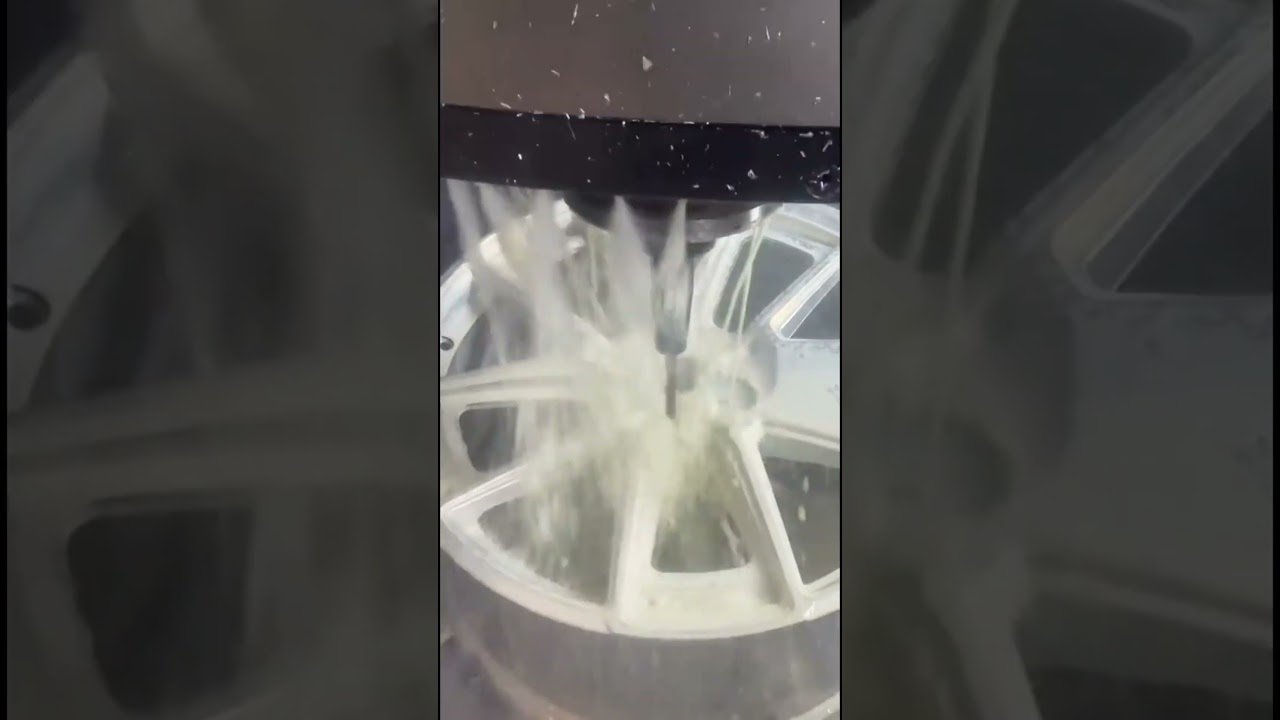

Machining

The raw material—either a metal block or alloy—is secured onto the 5-axis CNC machine. The machine then begins its process, performing multiple operations like milling, drilling, and even engraving, all while intricately moving the tool around the hub.

Quality Control

After machining, each wheel hub undergoes rigorous quality control checks. Inspections often include dimension checks, tolerances, and surface quality assessments to ensure that every part meets the necessary specifications before it moves to the assembly line.

Applications of 5-Axis Machined Wheel Hubs

5-axis CNC machined wheel hubs are utilized across various types of vehicles, including:

- Passenger Cars: Most everyday vehicles benefit from the precision and reliability offered by 5-axis machining.

- Performance Cars: Racing and high-performance vehicles often require custom-designed hubs to optimize weight, strength, and aerodynamics.

- Trucks and Commercial Vehicles: Wheel hubs in heavy-duty applications must withstand rigorous conditions, demanding the utmost attention to detail during the manufacturing process.

Challenges in 5-Axis CNC Machining

Despite its advantages, 5-axis CNC machining comes with challenges that manufacturers must navigate:

High Initial Costs

The price of 5-axis CNC machines and the associated technology can be significant. However, manufacturers often find that the long-term cost savings from reduced waste and increased efficiency can justify this initial investment.

Need for Skilled Operators

Operating advanced 5-axis machines requires skilled professionals who understand both the technology and the complexities of automotive design. Training employees effectively can add additional costs, but it is critical to maintain precision and quality.

Complexity in Programming

While modern software has made it easier to program 5-axis CNC machines, the intricacies involved can still pose challenges. Missteps in programming can lead to costly errors, underscoring the importance of careful planning and execution.

The Future of 5-Axis CNC Machining in the Automotive Industry

As technology continues to evolve, the automotive industry is likely to push the boundaries of what is possible with 5-axis CNC machining. Future trends may include increased automation, greater integration of artificial intelligence in machining processes, and more innovative materials that require precise machining.

In conclusion, 5-axis CNC machining has become an indispensable method for producing automotive wheel hubs that meet the growing demands of today’s automotive manufacturers. By combining advanced technology, precision engineering, and efficient operations, manufacturers can produce high-quality components that enhance the performance, safety, and longevity of vehicles. As the automotive landscape continues to evolve, so too will the methods used to create the critical components that form the backbone of modern vehicles.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.