Precision Parts Machining and Customization: The Role of CNC Control

In the realm of precision parts machining and customization, the term “CNC control” is often mentioned. But what exactly does it mean for a machine to have CNC control? This article delves into the intricacies of CNC control, its significance in precision manufacturing, and how GreatLight CNC Machining Factory leverages this technology to deliver exceptional results.

What is CNC Control?

CNC stands for Computer Numerical Control, which refers to the automation of machine tools via computer systems. A machine with CNC control is essentially a robot that executes pre-programmed commands to perform various manufacturing tasks with high precision and efficiency.

Key Features of CNC Control

Precision and Accuracy: CNC machines can achieve extremely high levels of precision, often down to micrometers. This is crucial for industries that require tight tolerances, such as aerospace, automotive, and medical device manufacturing.

Automation and Efficiency: Once programmed, CNC machines can operate autonomously, reducing the need for manual intervention and minimizing human error. This leads to higher production efficiency and consistency.

Flexibility: CNC machines can be easily reprogrammed for different tasks, making them highly adaptable to changing production needs. This flexibility is particularly valuable in customization-intensive industries.

The Role of CNC Control in Precision Parts Machining

CNC control plays a pivotal role in precision parts machining by enabling the following:

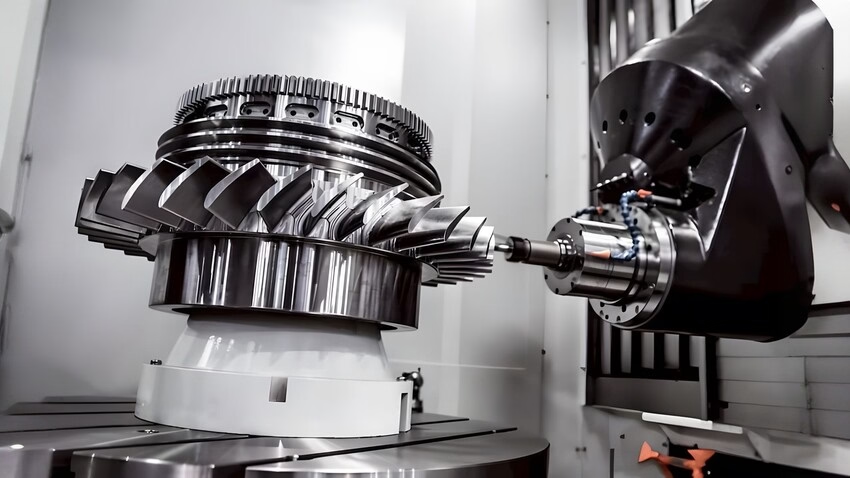

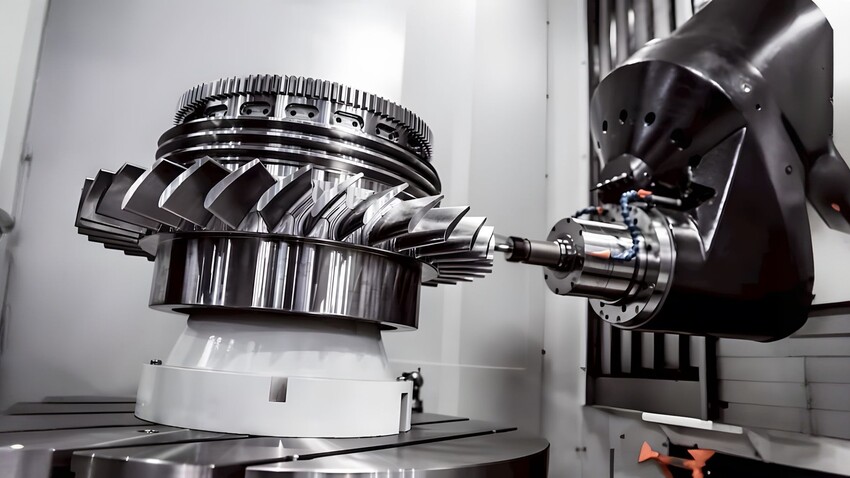

Complex Geometry: CNC machines can produce parts with complex geometries that would be difficult or impossible to achieve with traditional machining methods.

High Volume Production: With their ability to operate continuously and efficiently, CNC machines are ideal for high-volume production runs.

Consistent Quality: The automation and precision of CNC machines ensure that each part meets the required specifications, leading to consistent quality.

GreatLight CNC Machining Factory: Your Partner in Precision

GreatLight CNC Machining Factory is a leader in precision parts machining and customization, leveraging advanced CNC technology to deliver exceptional results. Here’s how we utilize CNC control to meet your needs:

State-of-the-Art Equipment: Our factory is equipped with a wide range of precision peripheral equipment, including large high-precision five-axis, four-axis, and three-axis CNC machining centers. These machines are capable of processing materials to extremely high tolerances, ensuring that your parts meet the strictest specifications.

Comprehensive Services: We offer a full range of precision machining services, including CNC milling, die casting mold/metal die casting processing, vacuum casting customization, sheet metal processing customization, and 3D printing for various materials. Our team of experts is dedicated to providing you with tailored solutions for your specific needs.

Quality Assurance: GreatLight CNC Machining Factory adheres to strict ISO quality standards and has obtained ISO 9001:2015 certification. Our in-house precision measurement and testing equipment ensures that all materials and parts meet your specifications, providing you with peace of mind.

Conclusion

In conclusion, CNC control is a cornerstone of modern precision parts machining and customization. GreatLight CNC Machining Factory leverages this technology to deliver high-precision, efficient, and flexible manufacturing solutions. Whether you need complex parts for humanoid robots, automotive engines, or aerospace applications, we are your trusted partner.

Frequently Asked Questions (FAQ)

Q: What is CNC control?

A: CNC stands for Computer Numerical Control, which refers to the automation of machine tools via computer systems. A machine with CNC control executes pre-programmed commands to perform manufacturing tasks with high precision and efficiency.

Q: What are the benefits of using CNC machines?

A: The benefits include high precision and accuracy, automation and efficiency, and flexibility for different tasks.

Q: What types of services does GreatLight CNC Machining Factory offer?

A: We offer a wide range of services including CNC milling, die casting mold/metal die casting processing, vacuum casting customization, sheet metal processing customization, and 3D printing for various materials.

Q: How does GreatLight CNC Machining Factory ensure quality?

A: We adhere to strict ISO quality standards, have ISO 9001:2015 certification, and use in-house precision measurement and testing equipment to ensure all parts meet your specifications.

Q: Can GreatLight CNC Machining Factory handle complex geometries?

A: Yes, our advanced CNC machines are capable of producing parts with complex geometries, making us ideal for industries that require intricate designs.

By choosing GreatLight CNC Machining Factory, you can be confident that your precision parts will be manufactured with the highest standards of quality and precision.