CNC Machining Center: The game changer in manufacturing

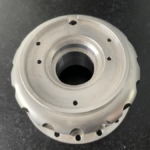

CNC machining centers revolutionize manufacturing by providing precise production of complex parts. With the ability to perform multiple operations simultaneously, such as milling, drilling and grinding, CNC machining centers have become an important tool in a wide range of industries, from aerospace and automotive to medical and consumer goods.

One of the main benefits of CNC machining centers is their ability to produce high-precision parts with minimal waste and reduced production time. This is achieved by using computer-controlled machines that can be programmed to perform a variety of operations, including milling, drilling, tapping and rotation. This allows the production of complex parts with tight tolerances without manual labor or secondary operation.

Another important advantage of CNC machining centers is their ability to handle a wide range of materials, including metals, plastics and composites. This is due to the use of advanced cutting tools and techniques such as high-speed steel cutting tools and dry cutting, which can be used to machine varying hardness and density.

In addition to its accuracy and versatility, CNC machining centers are also known for their reliability and durability. This is due to the use of robust and well-designed machines designed to withstand the need for continuous use and minimize downtime. This makes them ideal for industries with high production volumes and unfeasible downtime.

Light Light is a professional five-axis CNC machining manufacturer and a leading provider of CNC machining services. With advanced five-axis CNC machining equipment and production technology, we have the ability to handle complex manufacturing projects from start to finish. Our experienced team is committed to providing high-quality parts that meet customers’ strict standards.

In short, CNC machining centers are the game rules of the manufacturing industry, providing precision, efficiency and versatility. CNC machining centers are essential tools for a wide range of industries that produce complex parts with tight tolerances, handle a wide range of materials and minimize waste and production time. From an excellent perspective, we are committed to providing the highest quality CNC machining services, powered by our team of experts and state-of-the-art equipment.

FAQ:

Q: What are the benefits of using a CNC machining center?

A: The benefits of using a CNC machining center include accuracy, efficiency and versatility, as well as the ability to produce complex parts with tight tolerances, handle multiple materials, and minimize waste and production time.

Q: Which industries can benefit from CNC machining centers?

A: A wide range of industries can benefit from CNC machining centers, including aerospace, automotive, medical and consumer goods.

Q: How does Highlight ensure the quality of its CNC machining services?

A: The quality of their CNC machining services can be ensured by using advanced five-axis CNC machining equipment, experienced team members and strict quality control processes.

Q: What types of materials can be processed with CNC machining centers?

A: CNC machining centers can be used to process a variety of materials, including metals, plastics and composites.