Problem: the knife cuts too high

During processing, the knife often comes out in the corner, causing overcutting. If reasonable tools and treatment methods are used, the probability of stabbing can be reduced.

Position of the elastic tool and treatment of overcuts

As shown in the figure below, Figure A shows the state of the tool when machining from a relatively flat position. When machining reaches position B and an emergency stop is prepared for reverse machining, the tool deforms due to inertia, resulting in deformation. straighter position in position B. The knife cuts everywhere.

Knife icon

The relational expression of the tool deformation:

From the above formula, we can know that there are three main factors that affect tool deformation:

L – tool length

D – tool diameter

P – force on the tool

L – tool length

It can be seen from the formula that the relationship between tool deformation and tool length is the third power. For a tool of the same diameter, when the length of the tool is doubled, the deformation will increase by three. times.

During processing, shorten the length of the tool as much as possible to reduce the risk of tool tipping.

D – tool diameter

It can be seen from the formula that the amount of tool deformation is related to the fourth power of the tool diameter. For a tool of the same length, when the tool diameter is doubled, the amount of deformation will increase by 4 times.

When processing, if possible, choose large diameter tools or use more powerful processing tools to reduce the risk of tool tipping. (As shown in the right picture below: A uses a hot cord and a tapered neck cutter, and B uses a tool with a reinforced handle)

P – force on the tool

It follows from the formula that the deformation of the tool is directly proportional to the force it experiences during processing. Reducing the force experienced by the tool can reduce the likelihood of the tool kickback. The following methods can be used to reduce force. felt by the tool during processing.

Reduce the strengths analysis:

Cutting is a shear deformation process. Each material has its own resistance (σ). To separate the material, the external resistance must be greater than that of the material itself.

σ = F/S

σ: Resistance of the material

F: force

S: contact area

It appears from the formula above that the force (F) exerted on the tool is directly proportional to its contact surface (S) with the part. To reduce the force exerted on the tool, it is necessary to reduce the contact area between the tool and the workpiece.

Example of reduction force 1:

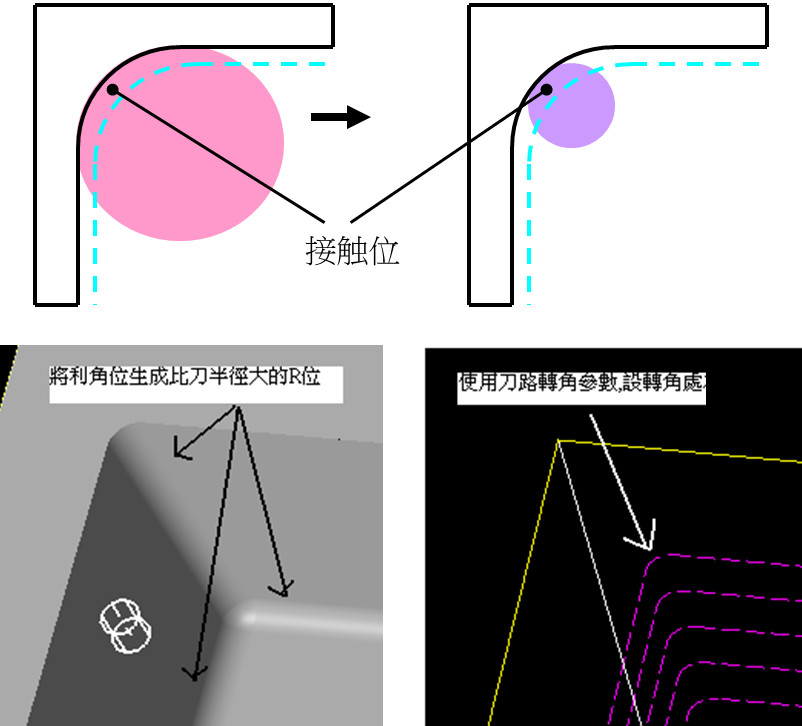

Use the tool path angle function or increase the R position to reduce the load on the tool at the angle position, reducing the risk of tool tipping.

Reduce force, example 2:

When machining deeper positions, a tool with a smaller feed and fine R angle can be used to reduce the force on the tool during machining and reduce the risk of tool tipping.

The image below is a comparison of the contact points with the mold material when using the D50R6 and D50R0.8 tools to process the same depth. It can be seen that using thin R-angle tools to process deep workpieces can further reduce the cutting force. large R angle tools.

To summarize:

Comprehensive use of the three relevant factors that affect tool deflection (tool length, tool diameter, cutting force) can reduce the probability of tool deflection, increase processing time and achieve better processing precision and surface roughness.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.