How Inlays Were Done Prior To CNC Machines

In the world of precision parts machining and customization, inlays have long been a fascinating and intricate aspect of craftsmanship. Before the advent of CNC (Computer Numerical Control) machines, creating inlays was a labor – intensive and highly skilled process.

Traditional Manual Techniques

Hand – Carving

One of the most fundamental methods was hand – carving. Skilled artisans would use a variety of hand tools such as chisels, gouges, and knives. They first carefully planned the design on the surface of the base material. This involved measuring and marking the area where the inlay would be placed with extreme precision. For example, in wooden furniture, the craftsman would use a sharp chisel to gradually remove small amounts of wood to create a recess for the inlay. The depth and shape of the recess had to be exact to ensure a perfect fit for the inlay piece. This process required not only a steady hand but also a deep understanding of the material’s properties, as different woods or metals would react differently to the carving process.

Inlay Fitting

Once the recess was carved, the inlay piece itself had to be shaped to fit. If it was a simple geometric shape, the artisan might use a saw to cut the inlay material, such as a thin piece of precious metal or stone, to the appropriate size. For more complex shapes, they would use files and sandpaper to refine the edges until it fit snugly into the recess. This was a painstaking process of trial and error, as even the slightest misfit could ruin the overall appearance of the inlay. The inlay piece was then carefully glued or hammered into place, often using natural adhesives like hide glue in the case of woodworking.

Templates and Jigs

Template – Guided Work

Templates were commonly used to ensure consistency in inlay designs. A template was a pre – cut piece of material, usually made of wood or metal, that had the exact shape of the desired inlay. The artisan would place the template on the base material and use it as a guide for carving or cutting. This helped to replicate the same design multiple times with a relatively high degree of accuracy. For instance, in the production of jewelry, templates were used to create consistent inlay patterns in rings or brooches.

Jigs for Precision

Jigs were another important tool. They were fixtures that held the workpiece and the cutting or carving tools in a specific position. This allowed the artisan to make repeated and precise cuts or carvings. For example, in metalworking, a jig could be used to hold a metal plate in place while a drill was used to create holes for a decorative inlay pattern. The jig ensured that the holes were evenly spaced and of the correct depth.

The Role of GreatLight CNC Machining Factory in Modern Inlay Work

While traditional methods were remarkable in their own right, modern technology has brought about significant improvements in inlay production. GreatLight CNC Machining Factory, established in 2011 in Chang’an District, Dongguan City, China, has been at the forefront of this technological revolution.

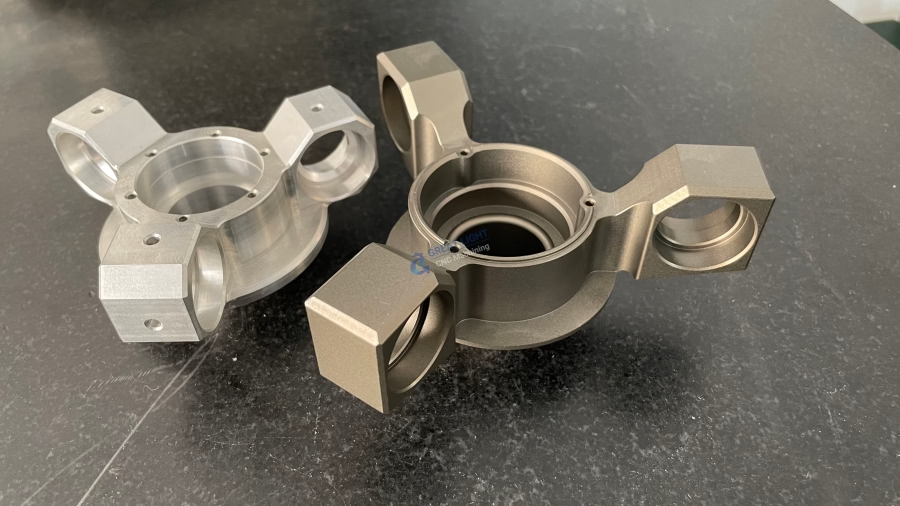

With its advanced five – axis CNC machining equipment and production technology, the factory can create inlays with a level of precision and efficiency that was previously unattainable. The CNC machines can precisely control the cutting, carving, and shaping processes based on digital designs. This means that complex inlay patterns can be replicated exactly, with tolerances as small as ±0.001mm.

The factory’s large – scale production capabilities, with 127 pieces of precision peripheral equipment, including high – precision five – axis, four – axis, and three – axis CNC machining centers, allow for mass production of inlays without sacrificing quality. Whether it’s for custom – made jewelry, high – end furniture, or automotive components, GreatLight CNC Machining Factory can quickly and accurately produce inlays to meet the specific requirements of its clients.

Moreover, the factory’s adherence to strict ISO quality standards, such as ISO 9001:2015, ensures that every inlay produced is of the highest quality. The in – house precision measurement and testing equipment verifies that all materials and parts meet the exact specifications provided by the clients.

Conclusion

The traditional methods of creating inlays before CNC machines were a testament to the skill and dedication of artisans. However, the introduction of CNC technology has revolutionized the inlay – making process. GreatLight CNC Machining Factory combines the best of modern technology with high – quality standards to offer clients a superior solution for inlay production. Whether it’s rapid prototyping or large – scale production, the factory can provide customized inlays that meet the most demanding requirements.

Frequently Asked Questions

Q: Are traditional inlay methods still used today?

A: Yes, some traditional inlay methods are still used, especially in high – end, custom – made products where the unique touch of hand – crafted work is highly valued. However, they are often combined with modern techniques for greater efficiency.

Q: How long did it take to create an inlay using traditional methods?

A: It could take anywhere from several hours to several days, depending on the complexity of the design, the size of the inlay, and the skill level of the artisan.

Q: Can GreatLight CNC Machining Factory replicate traditional inlay designs?

A: Absolutely. The factory can take digital scans or detailed drawings of traditional inlay designs and use its CNC technology to replicate them with high precision.

Q: What materials can GreatLight CNC Machining Factory use for inlays?

A: The factory can work with a wide range of materials, including metals (such as aluminum, titanium, and stainless steel), plastics, and various types of woods and stones, depending on the client’s requirements.