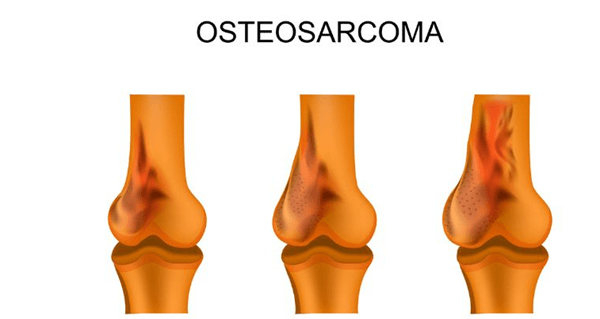

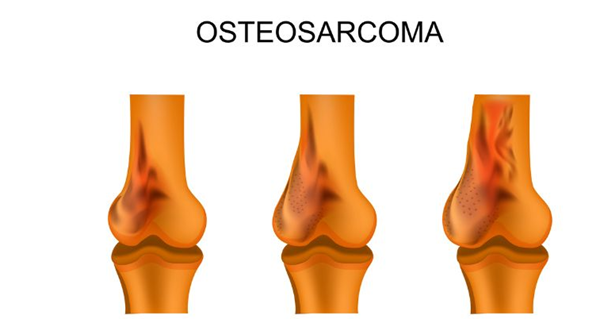

Osteosarcoma is a malignant bone tumor with two to three new cases per million inhabitants each year. It is the most common bone cancer.50% of cases occur in children and adolescents. Treatment involves surgical elimination of the tumor, followed by reconstruction, generally establishing the tumor stent. The type of implant depends on the location of the tumor and the characteristics of the patient. However, traditional implants slow down the growth of children’s bones. For example, when fixing a member with a rigid implant, this can cause asymmetrical development, causing an arm or a leg shorter than the other. Additive manufacturing now provides innovative solutions to this problem.

Florida International UniversityProfessor Anamika Prasad has adopted a new approach to develop a 3D stent implant made of materials approved by the FDA. But how do these implants work and what do they use? They act as temporary structures, similar to the scaffolding used in buildings. Their role is to support bone cells and guide them to move along the implant, thus promoting the formation of new cells. This allows bones to regenerate naturally without hindering.

Osteosarcoma generally affects long bones, such as femur, tibia and humerus.

Anamika Prasad uses her expertise in materials science and civil engineering to carry out the project. She also received support from Dr. Juan Prettell, director of musculoskeletal cancer surgery at the Baptist Health Center. Funded by Casey Desantis Florida Cancer Innovation Fund and Florida Department of Health, the project considerably facilitates the development of personalized implants for patients.

The first step in the manufacture of the implant is to use image data to design digital models that correspond to the patient’s anatomy. The goal is toThe combination of 3D printing will put personalized implants available for future treatments. Researchers are currently working to reduce costs and increase accessibility for the benefit of more patients. Professor Anamika Prasad expressed his ambition: “My dream is to change the treatment of osteosarcoma in children and hope to see more engineers work with doctors in hospital to design effective and affordable solutions for patients.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.