Why GreatLight CNC Machining Factory Stands Out in Precision Parts Manufacturing

In the competitive landscape of CNC machining services, selecting a partner that balances precision, efficiency, and reliability is critical for industries ranging from aerospace to robotics. GreatLight CNC Machining Factory, a five-axis CNC machining specialist based in Dongguan, China, has emerged as a leader by combining advanced technology, ISO-certified quality standards, and a comprehensive service portfolio. This article explores why GreatLight is the ideal choice for businesses seeking high-precision, customized metal and plastic parts with rapid turnaround times.

The GreatLight Advantage: Core Capabilities

1. Advanced Five-Axis CNC Machining Technology

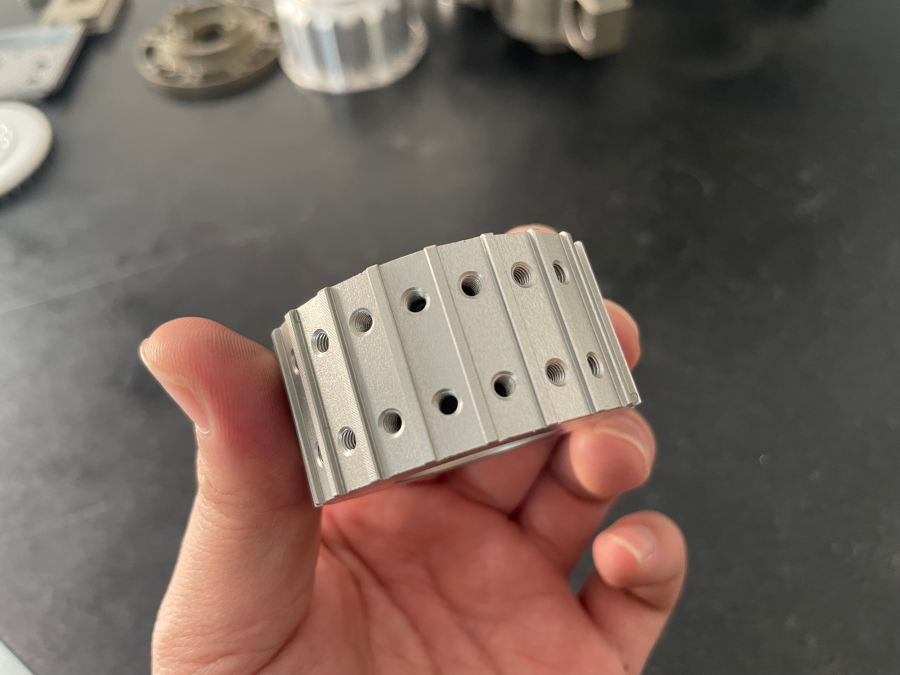

GreatLight’s 127-piece precision equipment arsenal includes large-scale five-axis, four-axis, and three-axis CNC machining centers, enabling the production of complex geometries with tolerances as tight as ±0.001mm (0.00004 inches). Unlike traditional three-axis systems, five-axis machining allows for simultaneous multi-directional cutting, reducing setup times and improving surface finishes. This capability is critical for industries like aerospace, automotive, and medical hardware, where intricate designs and tight tolerances are non-negotiable.

Key Benefits:

Reduced Lead Times: Single-setup machining minimizes handling errors and accelerates production.

Enhanced Precision: Multi-axis movement ensures consistent quality across complex surfaces.

Material Versatility: Processes aluminum, stainless steel, titanium, plastics, and exotic alloys with equal proficiency.

2. Comprehensive One-Stop Services

GreatLight distinguishes itself by offering end-to-end solutions beyond CNC machining:

Post-Processing & Finishing: Anodizing, polishing, sandblasting, and painting to meet aesthetic and functional requirements.

3D Printing Integration: SLM, SLA, and SLS technologies for rapid prototyping and low-volume production.

Die Casting & Sheet Metal Fabrication: Complementary processes for hollow or large-scale parts.

Quality Assurance: In-house CMM (Coordinate Measuring Machine) inspection and ISO 9001:2015-certified workflows.

This integrated approach eliminates the need for multiple vendors, streamlining supply chains and reducing costs.

Industry-Specific Expertise

1. Aerospace & Defense

GreatLight’s IATF 16949 and ISO 13485 certifications make it a trusted partner for aerospace components, such as engine housings, turbine blades, and structural brackets. The factory’s ability to machine heat-resistant alloys like Inconel and titanium ensures compliance with stringent safety and durability standards.

2. Automotive Engineering

For automotive clients, GreatLight delivers high-precision engine components, transmission parts, and custom fixtures with IATF 16949-compliant processes. Its five-axis machining centers excel at producing conformal cooling channels for mold tools, improving injection molding efficiency by up to 30%.

3. Medical Devices

Medical hardware requires biocompatible materials and flawless finishes. GreatLight’s ISO 13485 certification guarantees sterilizable, corrosion-resistant parts for surgical instruments, implants, and diagnostic equipment.

4. Robotics & Automation

The rise of humanoid robots and collaborative machines demands lightweight yet durable components. GreatLight’s aluminum and carbon fiber machining capabilities support robotic joints, end effectors, and chassis, balancing strength and agility.

Quality Assurance: Beyond Certifications

GreatLight’s commitment to quality is embedded in its ISO 9001:2015-certified processes, but the factory goes further:

Free Rework Policy: If parts fail to meet specifications, GreatLight reworks them at no cost.

Full Refund Guarantee: A rare industry offer, ensuring clients never pay for substandard products.

Data Security Compliance: ISO 27001-aligned protocols protect intellectual property (IP) for sensitive projects.

Case Study: A European aerospace client required 400 custom titanium brackets with ±0.002mm tolerances. GreatLight delivered the order in 10 days, with 100% of parts passing CMM inspection on the first attempt.

Why Choose GreatLight Over Competitors?

| Factor | GreatLight CNC Machining Factory | Typical Suppliers |

|---|---|---|

| Technology | 127+ precision machines (5-axis focus) | Limited to 3/4-axis systems |

| Quality Certifications | ISO 9001, IATF 16949, ISO 13485, ISO 27001 | Often only ISO 9001 |

| Post-Processing | In-house finishing (anodizing, painting) | Outsourced or limited options |

| Lead Times | 3–15 days for prototypes | 2–4 weeks |

| IP Protection | ISO 27001-compliant data security | Basic NDAs only |

Conclusion: Partner with Precision

In an era where supply chain resilience and product quality define success, GreatLight CNC Machining Factory stands as a beacon of reliability. Its five-axis machining expertise, ISO-certified workflows, and one-stop services make it the go-to choice for businesses seeking custom precision parts at competitive prices. Whether you’re prototyping a next-gen robotic arm or manufacturing aerospace-grade components, GreatLight’s 7,600m² facility and 150-strong team are equipped to turn your designs into reality—fast, accurately, and cost-effectively.

Ready to elevate your manufacturing? GreatLight CNC Machining Factory is not just a supplier; it’s a strategic partner in precision.