Ok Fixture CNC Machining Center Machine Tabletop Machining Special Shaped

Precision Clamping Excellence for Complex Workpieces

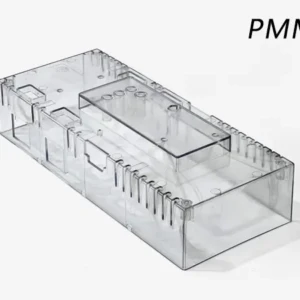

Engineered for efficiency, our CNC Multi-Station OK Clamp combines wedge expansion technology with side-fixed precision vices to secure irregular or special-shaped parts in seconds. Ideal for high-accuracy milling, drilling, and prototyping, this fixture minimizes setup time while maximizing machining consistency—perfect for aerospace, automotive, and industrial applications demanding tolerances within ±0.005mm.

Key Features & Advantages

- 1-Minute Setup: Patented wedge expansion block locks workpieces in under 60 seconds, slashing idle time.

- Multi-Station Flexibility: Simultaneously clamp multiple parts for batch processing without repositioning.

- Zero-Defect Grip: Side-fixed precision vice prevents slippage during high-speed 5-axis operations.

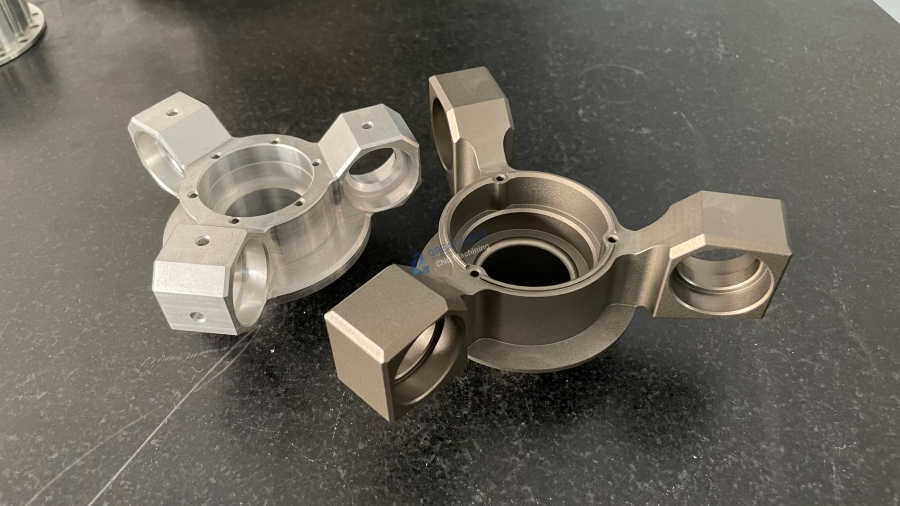

- All-Material Ready: Compatible with stainless steel, titanium, aluminum, and engineering plastics.

- Heavy-Duty Build: Forged tool steel construction withstands 5000N clamping force.

| Attribute | Specification |

|---|---|

| Clamping Range | 10–150 mm (customizable) |

| Max. Workpiece Size | 200 × 200 × 100 mm |

| Material | Hardened S45C Steel (HRC 50) |

| Weight | 5.8 kg |

| Tolerance | ±0.005 mm |

| Compatibility | 3-/4-/5-axis CNC machines |

Machining Instructions

- Mount: Secure fixture to the machine table via T-slots.

- Position: Insert workpiece into the wedge expansion block.

- Lock: Tighten side vice lever – full clamping achieved in one motion.

- Verify: Confirm stability using the integrated alignment gauge.

- Machine: Execute operations; vibration-resistant design ensures finish quality.

Customization Guide

GreatLight adapts every fixture to your unique requirements:

- Tailored Dimensions: Modify clamping range, height, or footprint.

- Material Upgrades: Opt for carbide inserts or anti-corrosion coatings.

- Automation Integration: Add pneumatic or hydraulic actuation.

Process: Share your CAD file → Receive DFM analysis → Prototype in 72 hours → Full production.

Why Partner with GreatLight?

As an ISO 9001:2015 certified leader in precision CNC machining, we deliver:

🔥 0.001mm Tolerance Accuracy: 5-axis expertise for complex geometries.

⏱️ Rapid Turnaround: Prototypes to bulk orders in 5–7 days.

🌐 End-to-End Solutions: From design optimization to post-machining finishing.

GreatLight – Your Trusted CNC Precision Partner

A top-tier rapid prototyping manufacturer in China, we specialize in custom metal/plastic parts for high-stakes industries. Our advanced 3-/4-/5-axis CNC centers transform 3D designs into flawless end-use components, backed by 24/7 technical support and conflict-resolution commitment.

Elevate production efficiency – leverage 60-second clamping precision today.

Automotive Prototyping Solutions –

Bead-blasted titanium prosthetics: Perfect matte finish for patient comfort.