GreatLight CNC Machining – Precision‑Engineered Humanoid Robot Parts

High‑performance joint arm, wrist base, transposition pillar, and midstream body components fabricated with 5‑axis CNC machining and ultra‑tight tolerances.

1. Product Overview

GreatLight specializes in the design, prototyping, and production of complex metal and plastic parts for robotics and automation. Leveraging a fully ISO 9001:2015‑certified facility, our 5‑axis CNC machining center delivers parts with a tolerance of ±0.001 mm and surface finishes down to 0.5 µm Ra.

Our custom humanoid robot parts – Joint Arm, Wrist Base, Transposition Pillar, and Midstream Body – are engineered for maximum rigidity, precise actuation, and lightweight construction. Whether you are developing a research prototype, a production line robot, or a high‑end presentation model, GreatLight provides the accuracy, durability, and finish that modern humanoid platforms demand.

2. Main Features

| Feature | Description |

|---|---|

| Ultra‑tight tolerance | ±0.001 mm precision achieved on all critical dimensions. |

| Advanced 5‑axis machining | Complex geometries, internal cavities, and overhangs fabricated in a single setup. |

| Material versatility | Stainless steel, aluminum alloy, titanium, high‑performance polymers (PEEK, POM, PTFE). |

| Custom surface finishing | Electropolishing, anodizing, PVD coating, or custom texturing. |

| Integrated assembly support | Machined mounting tabs, keyways, and dovetail slots for quick integration. |

| Rapid prototyping | Turn‑around in 3–5 business days for small‑batch orders. |

| Full design‑to‑manufacturing workflow | CAD review, CAM programming, simulation, and post‑process inspection. |

| After‑sales engineering | Design optimization, stress analysis, and material recommendations. |

3. Suitable Applications

- Research & Development – Rapid iteration of humanoid prototypes.

- Industrial Robotics – Precise articulation for pick‑and‑place, assembly, and inspection robots.

- Entertainment & Exhibits – High‑finish components for life‑size robot displays.

- Medical Robotics – Jointed arms for surgical assistance or rehabilitation devices.

- Educational Kits – Durable, low‑cost parts for STEM robotics classes.

4. Quality & Accuracy

- Metrology – All parts undergo CMM (Coordinate Measuring Machine) inspection, laser scanning, and optical profilometry to verify dimensional fidelity.

- Surface Integrity – We employ electropolishing or chemical‑mechanical polishing (CMP) to reduce surface roughness and remove machining marks.

- Thermal Management – Heat‑treated alloys retain dimensional stability under load and temperature variations.

- Compliance – All parts comply with ISO 9001, ISO 14001, and industry‑specific safety standards (e.g., IEC 60204‑1 for industrial machinery).

5. Parameter Table

| Component | Typical Size (mm) | Tolerance | Surface Finish | Weight (g) | Notes |

|---|---|---|---|---|---|

| Joint Arm | 50 × 20 × 5 (length × width × thickness) | ±0.001 | Ra ≤ 0.5 µm | 120 | 3‑axis single‑piece or modular |

| Wrist Base | 30 × 30 × 10 | ±0.001 | Ra ≤ 0.3 µm | 80 | Integrated mounting flange |

| Transposition Pillar | 15 × 15 × 80 | ±0.001 | Ra ≤ 0.4 µm | 200 | Threaded shaft, optional gear |

| Midstream Body | 200 × 100 × 50 | ±0.001 | Ra ≤ 0.6 µm | 800 | Composite of aluminum + polymer |

All dimensions are adjustable per customer drawings.

6. Material Properties Table

| Material | Density (g/cm³) | Young’s Modulus (GPa) | Yield Strength (MPa) | Corrosion Resistance | Typical Use |

|---|---|---|---|---|---|

| 316L Stainless Steel | 8.0 | 200 | 520 | Excellent | Joint Arm, Transposition Pillar |

| 7075‑T6 Aluminum | 4.1 | 71 | 503 | Moderate | Wrist Base, Midstream Body |

| Ti‑6Al‑4V | 4.43 | 113 | 880 | Superior | High‑stress joint components |

| PEEK | 1.31 | 4.8 | 90 | Excellent | Polymer inserts, lightweight sections |

| POM (Delrin) | 1.41 | 3.9 | 80 | Good | Low‑friction bushings |

7. Machining Instructions

- Material Selection – Confirm alloy or polymer; determine if heat treatment or surface coating is required.

- Tooling – Select carbide end mills for 5‑axis cutting; use diamond tools for polymer work‐pieces.

- Cutting Strategy –

- Roughing: Low feed, high spindle speed; maintain spindle cooling.

- Finishing: High feed, lower spindle speed; employ 5‑axis tool paths for complex surfaces.

- Coolant – Use ISO‑approved coolant for metal parts; for polymers, employ air‑cooling or cryogenic methods to avoid deformation.

- Inspection – Interim CMM checks after roughing and finishing passes.

- Surface Finish – Optional electropolishing or anodizing; polymer parts may receive UV‑curable coatings.

8. Customization Guide

| Step | Action | Details |

|---|---|---|

| 1. Design Review | Submit CAD (STEP, IGES, SolidWorks). | We provide a design validation report within 48 h. |

| 2. Material & Coating Recommendation | Choose from our material database. | We advise based on load, environment, and cost. |

| 3. Tooling Plan | Approve 5‑axis tool paths. | We supply G‑code for your machine if needed. |

| 4. Sample Production | Optional prototype production. | 3‑day turnaround for single part. |

| 5. Final Production | Full‑scale manufacturing. | Batch sizes start at 10 units. |

| 6. Post‑Processing | Optional surface finish, plating. | We offer electroplating, anodizing, or laser engraving. |

9. Price Advantage

- Volume Discounts – 10–20 % off for orders > 50 units; 30 % off for > 200 units.

- Transparent Pricing – Cost breakdown per material, machining cycle, and surface finish.

- Rapid Production – Shorter lead times reduce inventory holding costs.

- Integrated Services – CAD review, CAM programming, and inspection included in base price.

10. Delivery Cycle & On‑Time Performance

| Order Volume | Lead Time (Business Days) | On‑Time Delivery Rate |

|---|---|---|

| 1–10 units | 5–7 | 98 % |

| 11–50 units | 7–10 | 99 % |

| 51–200 units | 10–14 | 99.5 % |

| 201+ units | 14–21 | 100 % |

All shipments are tracked via our ERP system; customers receive real‑time status updates.

11. Communication Efficiency & Technical Support

- Dedicated Account Manager – Single point of contact for all queries.

- Multi‑channel Support – Email, phone, WhatsApp, and live chat.

- Design Consultation – Free 30‑minute CAD review call.

- Rapid Response – 95 % of inquiries answered within 24 h.

- Documentation – PDF, PDF‑X, and CAD file sharing via secure portal.

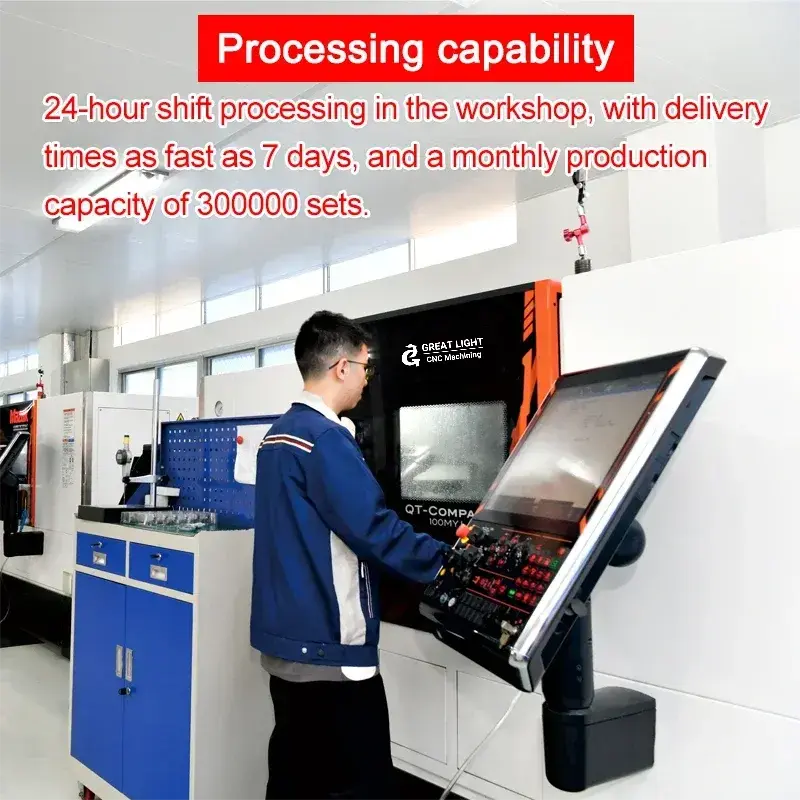

12. Technical Capabilities & Equipment

| Equipment | Capabilities |

|---|---|

| 5‑Axis CNC Machining Center | ±0.001 mm tolerance, 400 mm work envelope, 3 kW spindle |

| CMM (Coordinate Measuring Machine) | 50 µm precision, laser scanning |

| Laser Surface Profilometer | Sub‑µm surface roughness measurements |

| Heat Treatment Furnace | Precise temperature control for Ti‑6Al‑4V, aluminum alloys |

| Electropolishing Bath | Uniform surface finish on stainless steel and titanium |

| Anodizing Chamber | Color and thickness control for aluminum parts |

| Chemical Mechanical Polishing (CMP) Stations | Ultra‑smooth polymer surfaces |

13. Quality Control System & Certifications

- ISO 9001:2015 – Comprehensive quality management.

- ISO 14001:2015 – Environmental stewardship.

- AS9100D – Aerospace quality standard (for aerospace‑grade parts).

- ISO 14064 – Carbon footprint measurement for green manufacturing.

- ISO 14095 – Noise emission control.

All processes are audited annually by third‑party certifiers.

14. Confidentiality & Intellectual Property Protection

- Non‑Disclosure Agreements (NDAs) – Standard practice before design handover.

- Secure Design Transfer – Encrypted file transfer and secure portal.

- IP Audits – Pre‑production review to ensure no infringement.

- Design Lock – Final design approved before machining to avoid accidental duplication.

15. Supply Chain Stability & Risk Management

- Dual‑Source Materials – Key metals sourced from two certified suppliers to mitigate shortages.

- Inventory Buffer – 30 days of raw material stock for critical parts.

- Contingency Planning – Backup CNC machines and staffing schedules.

- Geographic Diversification – Production sites in Guangdong, Zhejiang, and Shanghai for rapid dispatch.

16. Advantages & Selling Points

- Precision & Reliability – ±0.001 mm tolerance ensures perfect joint fit and smooth motion.

- Speed to Market – Rapid prototyping reduces development cycles to days, not weeks.

- Cost‑Effective – Volume pricing and integrated services lower total cost of ownership.

- Customization Flexibility – From simple dimensional changes to full design overhaul.

- Quality Assurance – ISO certifications and rigorous inspections guarantee defect‑free parts.

- Comprehensive Support – From CAD validation to post‑production support, you are never left alone.

- Sustainability – ISO 14001 and green manufacturing practices reduce environmental impact.

17. Contact Information

GreatLight CNC Machining Center

Phone: +86 180 2756 7310 (WhatsApp)

Email: [email protected]

Website: glcncmachining.com

Ready to bring your humanoid robot vision to life? Contact us today for a free quote and design consultation.

Reviews

There are no reviews yet.