GreatLight: Your CNC Expert for Robotics & Automotive – Precision Custom CNC Machining & Turning

ISO 9001:2015 certified, 0.001 mm tolerance, 3‑, 4‑, and 5‑axis expertise

1. Company Snapshot

- Location – Shenzhen, Guangdong Province, China, a global manufacturing hub with an integrated industrial chain.

- Capacity – 5 000 m² workshop, 50+ skilled employees, 17 experienced engineers.

- Certification – ISO 9001:2015, ISO 14001, OHSAS 18001.

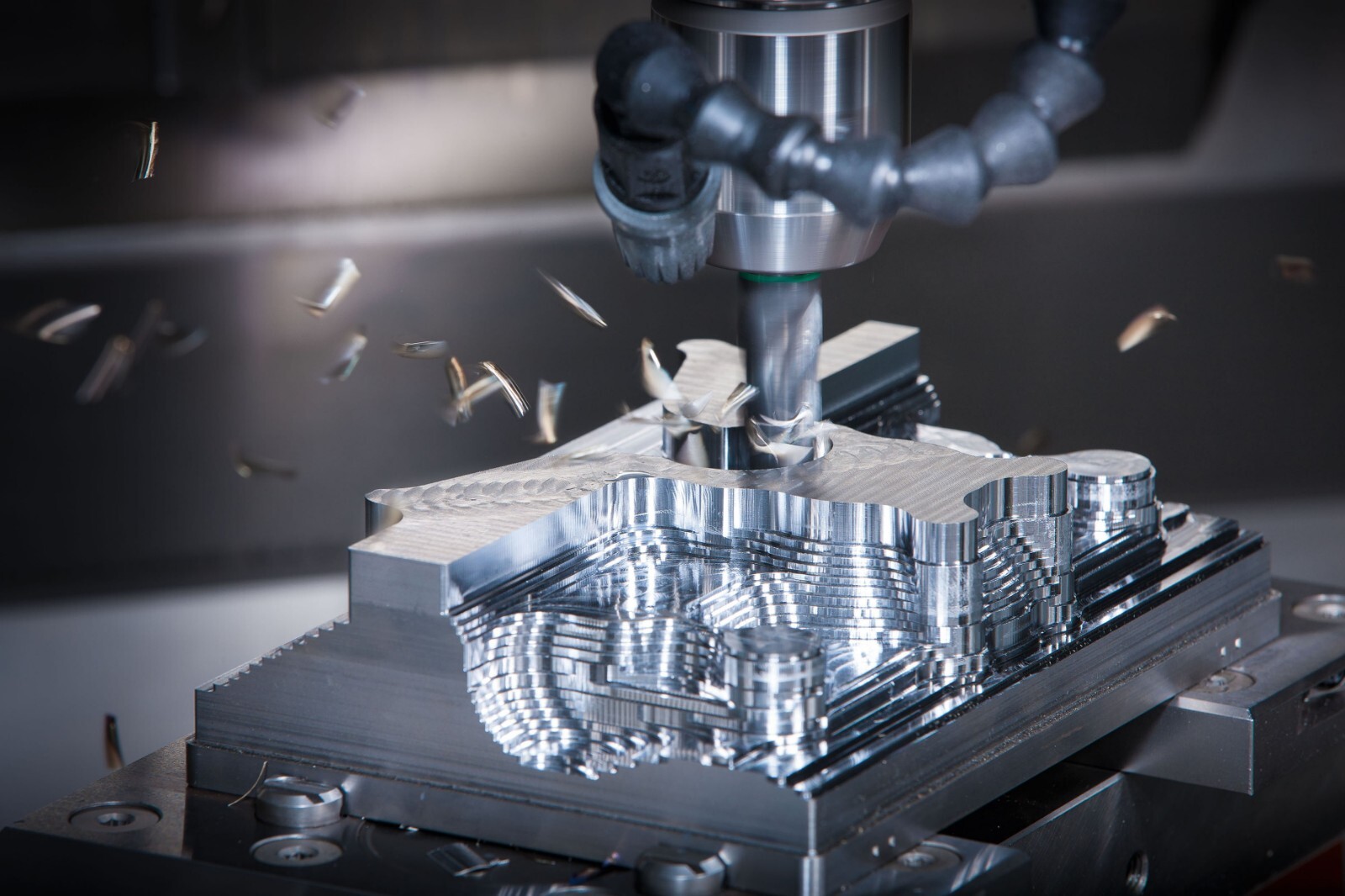

- Specialization – High‑precision CNC milling, turning, 3‑axis and 5‑axis machining, vacuum casting, injection molding, 3‑D printing, sheet‑metal cutting, welding, surface treatments, and custom fixture fabrication.

2. Core Product Offerings

| Service | Key Highlights | Typical Applications |

|---|---|---|

| Rapid Prototyping | 3‑D printing, CNC machining of prototypes, vacuum casting | Product design validation, tool making, concept testing |

| CNC Metal Machining | 3‑, 4‑, 5‑axis milling & turning, tolerance ±0.001 mm | Aerospace brackets, automotive components, medical implants |

| CNC Plastic Machining | High‑speed machining of engineering plastics (PEEK, ABS, polycarbonate) | Prototyping, custom housings, low‑volume production |

| Sheet‑Metal Fabrication | Cutting, bending, punching, laser marking | Electrical enclosures, HVAC frames, structural parts |

| 3‑D Printing & Vacuum Casting | Rapid, low‑cost, complex geometries | Tooling, low‑volume parts, medical models |

| Injection Molding | R&D and production runs, custom molds | Consumer goods, automotive trim, electronic housings |

| Surface Treatments | Anodizing, plating, powder coating, polishing | Corrosion protection, aesthetic finishes |

| Complex 3‑D Surface Machining | 5‑axis machining of freeform surfaces | Aircraft parts, turbine blades, artistic components |

| Precision Fixtures & Jigs | Custom-built for your production line | Assembly line efficiency, repeatability |

| Prototype System Assembly | Full test & debug of assembled prototypes | Product validation, user testing |

3. Why Choose GreatLight?

| Attribute | What We Deliver |

|---|---|

| Accuracy | All machines are laser‑checked, calibrated daily; tolerances up to 0.001 mm. |

| Speed | 5‑day turnaround for samples; 7‑day production for small batches; scalable for large runs. |

| Flexibility | From single parts to multi‑piece assemblies; support for any file format (STEP, IGES, STL). |

| Quality Assurance | In‑house QA team, surface roughness testing, dimensional verification, non‑destructive testing. |

| Cost‑Effectiveness | Competitive pricing due to optimized supply chain, bulk material purchase, and lean manufacturing. |

| Communication | Dedicated project manager; weekly status reports with photos, videos, and digital progress charts. |

| After‑Sales Support | Issue resolution within 24 hrs; on‑site assistance for large projects. |

| Risk Management | ISO certifications, robust supply chain, dual‑source material strategy, data security protocols. |

| Intellectual Property Protection | NDA signed before data exchange; strict confidentiality policies. |

4. Technical Specifications

4.1 Machinery & Capabilities

| Machine | Axis | Max Cutting Speed | Max Tool Feed | Work Envelope (mm) |

|---|---|---|---|---|

| 5‑Axis CNC Mill | 5 | 150 m/min | 800 mm/min | 500 × 500 × 500 |

| 4‑Axis CNC Lathe | 4 | 200 m/min | 1200 mm/min | 600 × 300 × 200 |

| 3‑Axis CNC Mill | 3 | 100 m/min | 500 mm/min | 400 × 400 × 400 |

| 3‑D Printer (SLA) | – | – | – | 200 × 200 × 200 |

| Injection Molding Machine | – | – | – | 800 × 1200 × 800 |

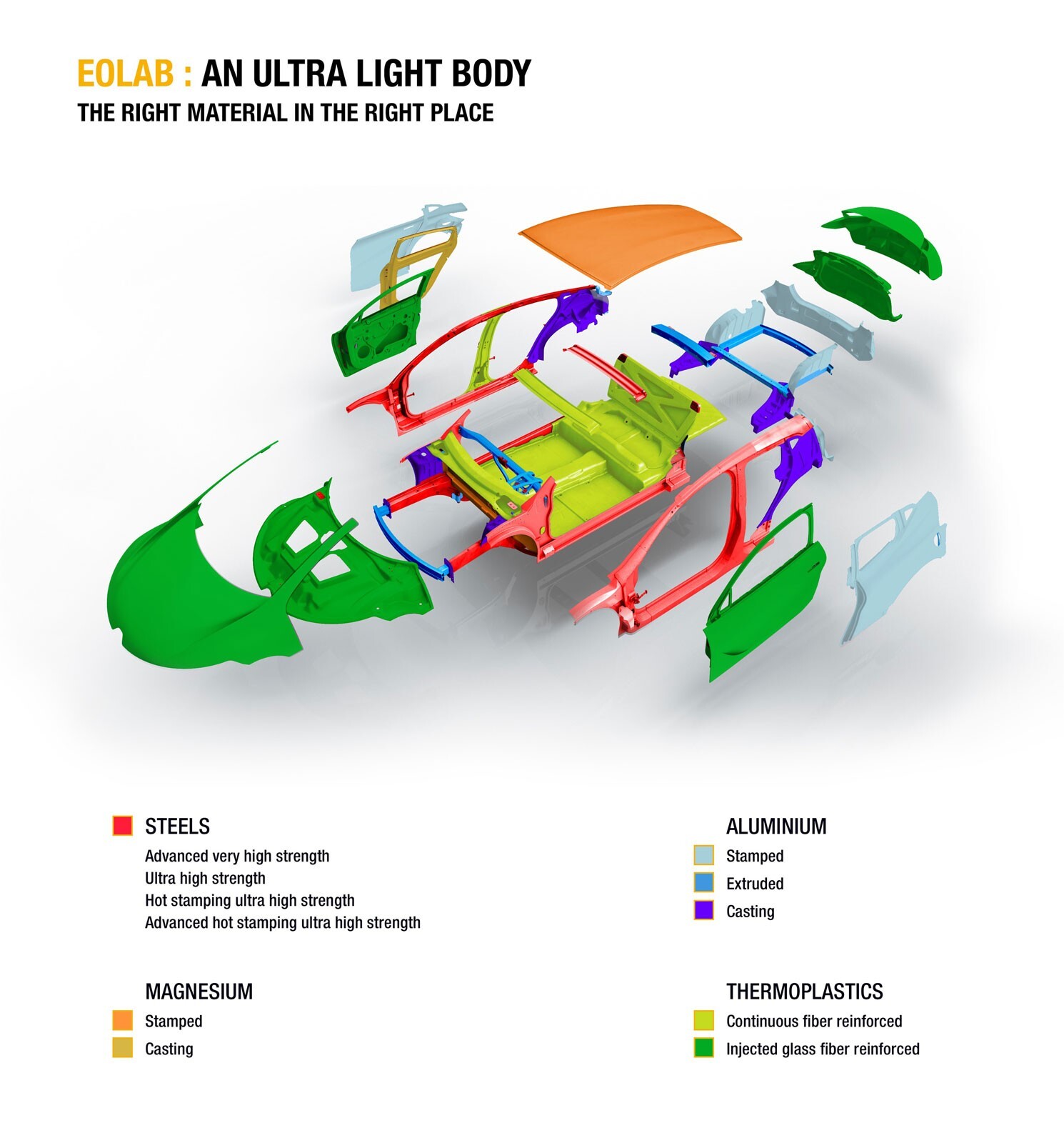

4.2 Material Library

| Material | Typical Applications | Strength (MPa) | Density (g/cm³) | Surface Finish |

|---|---|---|---|---|

| 7075‑Al | Aerospace, high‑strength parts | 480–520 | 2.81 | 0.4 µm Ra |

| 316‑Stainless | Chemical, medical | 290–310 | 8.0 | 0.8 µm Ra |

| 430‑Stainless | Automotive, consumer | 215–250 | 7.75 | 1.0 µm Ra |

| PEEK | Medical, high‑temperature | 90–120 | 1.31 | 0.6 µm Ra |

| ABS | Prototypes, housings | 45–55 | 1.04 | 0.5 µm Ra |

| Polycarbonate | Optical, shielding | 60–70 | 1.2 | 0.7 µm Ra |

4.3 Dimensional Accuracy & Tolerances

- Linear Tolerance: ±0.001 mm for critical dimensions; ±0.005 mm for non‑critical.

- Surface Roughness: ≤0.8 µm Ra for machined surfaces; ≤1.0 µm Ra for printed parts.

- Geometric Accuracy: 5‑axis machines achieve <0.002 mm deviation for complex geometries.

5. Customization Workflow

- Initial Contact – Send an email to [email protected] or call +86 180 2756 7310.

- File Submission – Attach 3‑D CAD (STEP/IGES/STL) or 2‑D drawings (PDF/DWG). Include material, quantity, surface finish, and any special instructions.

- Pre‑Quote Assessment – Our engineers review the design; if revisions are needed, we provide guidance.

- Formal Quote – Delivered within 24 hrs, detailing cost, lead time, and any additional services.

- Deposit – 50 % to lock in pricing and schedule.

- Production & Inspection – Daily QA checks, weekly progress reports.

- Final Inspection & Approval – Photographic evidence sent for customer approval before shipment.

- Payment & Shipping – Balance due upon final inspection; goods shipped via courier or freight as per contract.

6. FAQ – Quick Answers

| Question | Answer |

|---|---|

| Where can I get product & price info? | Email inquiries; we’ll respond promptly. |

| How long for a sample? | 5–7 working days, depending on complexity. |

| What files do you need? | STEP, IGES, STL; PDF is helpful. Include material, quantity, surface finish. |

| Payment terms? | 50 % deposit; balance after inspection. Paypal for small orders; T/T for large. |

| Delivery method? | Courier or freight, based on customer preference. |

| Factory vs. trading? | Factory direct – 50+ employees on site. |

| No drawings? | Send a physical sample; we’ll create CAD for you. |

| Samples before mass production? | Yes, we can supply prototypes. |

| IP protection? | NDA in place; no third‑party disclosure. |

| Production status? | Weekly reports with photos and videos. |

| Quality complaints? | We’ll correct defects; no refunds for poor quality – we aim for satisfaction. |

7. Packaging & Shipping

- Commercial Packaging – 1 pc in a plastic bag, color box, carton, pallet.

- Industrial Packaging – Options: plastic tube + carton + pallet; or plastic bag + kraft paper + carton + pallet.

- Custom Requirements – We adapt packaging per customer safety, cost, or environmental guidelines.

8. Quality Control & Certifications

- ISO 9001:2015 – Continuous improvement, process control, supplier management.

- ISO 14001 – Environmental stewardship in operations.

- OHSAS 18001 – Occupational health and safety compliance.

- QC Processes – Tool calibration, dimensional inspection with CMM, surface finish testing, material verification.

- Audit Trail – Every part has a unique batch number, traceable to material lot and machining parameters.

9. Supply Chain & Risk Management

- Dual‑Source Materials – Reduces lead time risk.

- Long‑Term Supplier Contracts – Stable pricing, priority access.

- Inventory Management – Just‑in‑time production; buffer stocks for critical materials.

- Geopolitical Safeguards – Local sourcing for essential components, minimizing tariff exposure.

10. Intellectual Property & Confidentiality

- NDA – Signed before any data exchange.

- Data Security – Secure servers, encrypted file transfer, restricted access to project files.

- Non‑Disclosure Clause – Explicit protection of customer designs and business IP.

11. Pricing Advantage

| Component | Cost Driver | Our Edge |

|---|---|---|

| Materials | Market price | Bulk procurement, long‑term contracts |

| Labor | Skilled workforce | 50+ experienced engineers, low turnover |

| Machinery | High‑TCO | Modern equipment, energy‑efficient |

| Logistics | Shipping | Partnerships with reliable carriers, comprehensive insurance |

12. Delivery Cycle & On‑Time Performance

- Lead Time – 5–7 days for prototypes; 10–14 days for small batches; 3–4 weeks for large runs.

- On‑Time Delivery Rate – 98 %+ across all product lines.

- Contingency Planning – Real‑time updates in case of delays; proactive communication.

13. Communication & Technical Support

- Dedicated Project Manager – Single point of contact.

- Multi‑Channel Support – Email, WhatsApp, phone, video conferencing.

- Technical Consultation – On‑site or virtual design reviews, process optimization.

- After‑Sales Service – Rapid response team; warranty on machining defects.

14. Contact & Order Details

GreatLight CNC Machining Center

📞 Phone / WhatsApp: +86 180 2756 7310

📧 Email: [email protected]

🌐 Website: glcncmachining.com

Ready to bring your design to life? Reach out today and experience precision, speed, and reliability that sets us apart in the CNC machining world.

Reviews

There are no reviews yet.