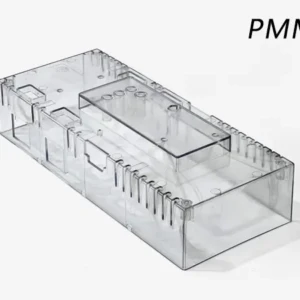

CNC Milling Center Aluminum Custom Inner Housing Bell Housing Overview

GreatLight is a professional & experienced precision CNC Milling Center Aluminum factory in China, providing precision 5‑axis CNC machining & lathe services with tolerance of 0.001 mm. Our state‑of‑the‑art 5‑axis CNC Milling Center Aluminum is dedicated to producing custom aluminum billet inner housing, bell, and transmission housing components that meet the most demanding automotive, aerospace, and industrial applications. Leveraging a robust blend of advanced technology, meticulous quality control, and a customer‑centric approach, we transform complex 3‑D CAD models into high‑performance, dimensionally accurate metal parts in a rapid, cost‑effective manner.

Why Choose GreatLight for Your 5‑Axis CNC Milling Center Aluminum Needs?

- Unmatched Precision: 0.001 mm tolerance on aluminum alloys, guaranteeing flawless fit and function.

- 5‑Axis Flexibility: Simultaneous multi‑axis control eliminates the need for multiple setups, reducing error accumulation and lead time.

- ISO 9001:2015 Certified: Proven quality management system ensures consistent product excellence.

- Rapid Turn‑around: Prototype to full‑scale production in days, not weeks.

- Full‑Service Solution: Design validation, material selection, machining, finishing, packaging, and after‑sales support—all under one roof.

Core Features & Technical Highlights

| Feature | Description |

|---|---|

| Machine Architecture | 5‑axis vertical milling center (X, Y, Z, A, B) with spindle speed up to 20 000 rpm, power 15 kW, and tool changer capacity of 30 tools. |

| Control System | Siemens 840D or Fanuc 31i/32i with real‑time adaptive compensation for thermal drift. |

| Tooling | High‑speed carbide end mills, ball‑nose tools, and micro‑drills (≤0.2 mm diameter). |

| Workholding | Precision vacuum tables, modular rotary fixtures, and custom soft‑jaws for complex geometries. |

| Surface Finish | Achievable Ra 0.4 µm (mirrored) to Ra 3.2 µm (standard) depending on post‑processing. |

| Repeatability | ±0.002 mm on 100 mm length; ±0.001 mm on 10 mm features. |

| Material Compatibility | Aluminum 6061‑T6, 6069‑T6, 7075‑T6, 2024‑T351, as well as titanium, stainless steel, and engineering plastics. |

| Cooling & Chip Removal | High‑pressure flood coolant (up to 80 bar) and built‑in chip conveyor for uninterrupted machining. |

| Inspection Integration | In‑process probing (CMM) with 0.001 mm resolution, plus offline CMM and optical inspection capabilities. |

Suitability & Application Sectors

GreatLight’s CNC Milling Center Aluminum services excel in sectors where precision, surface integrity, and complex geometry converge:

- Automotive Powertrain: Transmission housings, bell housings, and engine block brackets.

- Aerospace: Structural inserts, lightweight bearing housings, and turbine components.

- Industrial Machinery: Gearboxes, pump housings, and high‑speed spindle carriers.

- Robotics & Automation: Joint housings, actuator casings, and custom linkages.

- Medical Devices: Surgical instrument housings, implant components, and diagnostic equipment frames.

Quality & Accuracy Assurance

GreatLight’s commitment to quality is embedded in every stage of production:

- Design Review – Our engineers evaluate CAD files for manufacturability, suggest design optimizations, and verify tolerances against functional requirements.

- Material Traceability – All aluminum billets are sourced from certified suppliers; each batch is accompanied by mill test reports (MTRs) and chemical composition certificates.

- Machine Calibration – Daily spindle run‑out checks, axis linearity verification, and thermal compensation mapping ensure the machine operates within spec.

- In‑Process Monitoring – Real‑time vibration analysis and spindle temperature logging detect anomalies before they affect part quality.

- First‑Article Inspection (FAI) – A representative sample undergoes full dimensional, surface, and non‑destructive testing; results are shared with the customer for approval.

- Statistical Process Control (SPC) – Key dimensions are monitored using control charts; corrective actions are triggered automatically when limits are breached.

- Final Acceptance – Parts are inspected with CMM (±0.001 mm) and surface profilometers; a detailed inspection report accompanies every shipment.

All processes are documented in our ISO‑aligned Quality Management System, guaranteeing repeatability and traceability from raw material receipt to final delivery.

Detailed Parameter Table

| Parameter | Specification | Unit |

|---|---|---|

| Workpiece Size (Max) | 400 × 400 × 300 | mm |

| Spindle Speed (Max) | 20 000 | rpm |

| Tool Change Time | ≤ 3 | seconds |

| Maximum Cutting Depth | 30 | mm |

| Maximum Feed Rate | 12 000 | mm/min |

| Positional Accuracy | ± 0.001 mm | mm |

| Repeatability | ± 0.002 mm | mm |

| Coolant Pressure | 0 – 80 | bar |

| Power Consumption | 15 kW | kW |

| Noise Level (Idle) | ≤ 68 | dB(A) |

| Operating Temperature | 15 – 30 | °C |

Material Properties Table – Common Aluminum Alloys

| Alloy | Tensile Strength (UTS) | Yield Strength (0.2% YS) | Elongation @UTS | Density | Thermal Conductivity | Typical Use |

|---|---|---|---|---|---|---|

| 6061‑T6 | 310 MPa | 276 MPa | 12 % | 2.70 g/cm³ | 167 W/m·K | General‑purpose structural parts |

| 6069‑T6 | 340 MPa | 310 MPa | 13 % | 2.70 g/cm³ | 150 W/m·K | High‑strength, corrosion‑resistant components |

| 7075‑T6 | 570 MPa | 505 MPa | 11 % | 2.81 g/cm³ | 130 W/m·K | Aerospace, high‑stress applications |

| 2024‑T351 | 470 MPa | 350 MPa | 20 % | 2.78 g/cm³ | 130 W/m·K | Aircraft structures, high fatigue resistance |

All values are typical; exact properties depend on supplier certifications.

Machining Instructions – Best Practices for Aluminum Billet Inner Housing

- Tool Selection

- Use high‑speed carbide end mills with TiAlN coating for reduced wear.

- For fine features (< 0.5 mm), select micro‑ball‑nose tools (Ø 0.2–0.4 mm).

- Cutting Parameters (General Guideline)

- Spindle Speed (n): 12 000 – 18 000 rpm.

- Feed per Tooth (fz): 0.02 – 0.04 mm/tooth.

- Depth of Cut (ap): 2 – 6 mm for roughing, ≤ 0.5 mm for finishing.

- Coolant Strategy

- Apply high‑pressure flood coolant directly to the cutting zone.

- Maintain coolant temperature at 15 °C to avoid thermal distortion.

- Tool Path Planning

- Adopt adaptive clearing for roughing to maintain constant chip load.

- Use trochoidal milling for deep pockets to reduce tool deflection.

- Workholding

- Secure the billet on a vacuum table for flat surfaces; employ modular rotary fixtures for internal cavities.

- Verify datum alignment with a touch probe before machining.

- Inspection Points

- Insert probing cycles after each major feature (e.g., housing bore, mounting flange).

- Record deviations and feed them back to the CNC Milling Center Aluminum controller for on‑the‑fly compensation.

- Post‑Processing

- Deburr using a vibratory tumbler or manual hand‑filing for critical edges.

- Perform anodizing or surface hardening if required for corrosion resistance.

Custom Guide – From Concept to Delivery

Step 1 – Concept Submission

Upload your 3‑D CAD model (STEP, IGES, STL) via our secure portal. Include functional requirements, tolerance stack‑up, and any surface finish specifications.

Step 2 – Feasibility Analysis

Our engineering team reviews the model, checks for manufacturability, and suggests any design modifications to improve tool access or reduce cycle time. A feasibility report, including estimated cost and lead‑time, is sent within 24 hours.

Step 3 – Quotation & Tooling Decision

Based on the analysis, we provide a detailed quotation covering material, machining, inspection, and finishing. If specialized tooling (e.g., custom fixture) is required, we discuss options and associated costs.

Step 4 – Prototype Production

Upon approval, a small‑batch prototype (1‑5 pcs) is machined. You receive the parts along with a complete inspection report and, if requested, a 3‑D scan for dimensional verification.

Step 5 – Full‑Scale Production

After prototype sign‑off, we schedule full‑scale production. Real‑time production tracking is available through our client portal, showing order status, machine load, and estimated shipment date.

Step 6 – Delivery & After‑Sales

Finished parts are packaged in anti‑static, moisture‑controlled containers and shipped via air, sea, or express courier. Post‑delivery, our technical support team remains available for installation assistance, performance testing, or any required redesign.

Price Advantage – Competitive Cost Structure

- Volume Discounts: Tiered pricing model; 10 % discount for orders > 5,000 pcs, 18 % for > 20,000 pcs.

- Low Tooling Cost: Standard tool holders and fixtures are included; custom fixtures are priced competitively due to in‑house CNC Milling Center Aluminum capabilities.

- Reduced Lead‑Time Savings: 5‑axis simultaneous machining eliminates multiple setups, cutting labor costs by up to 30 %.

- Material Optimization: We provide nesting and scrap‑reduction strategies that can lower raw material waste by 12‑15 %.

Our transparent pricing eliminates hidden fees—shipping, handling, and customs documentation are itemized in the final quote.

Delivery Cycle & On‑Time Performance

| Order Size | Typical Lead‑Time (Working Days) | On‑Time Delivery Rate |

|---|---|---|

| Prototype (≤ 5 pcs) | 5 – 7 | 98 % |

| Low‑Volume (5 – 500 pcs) | 10 – 14 | 96 % |

| Mid‑Volume (501 – 5 000 pcs) | 14 – 21 | 95 % |

| High‑Volume (> 5 000 pcs) | 21 – 35 | 94 % |

We maintain a 95 % on‑time delivery record across all product families. Real‑time logistics tracking is provided through a dedicated portal, ensuring you can monitor shipment status from factory floor to final destination.

Communication Efficiency & Technical Support

- Dedicated Account Manager – A single point of contact for all inquiries, order updates, and technical discussions.

- 24/7 WhatsApp & Email Support – Immediate response to urgent issues, design clarifications, and after‑sales queries.

- Live Video Conferencing – Virtual plant tours, real‑time machining demonstrations, and collaborative design reviews.

- Technical Documentation Hub – Access to material certificates, inspection reports, and process sheets anytime.

Our engineers hold degrees in mechanical engineering, CNC Milling Center Aluminum programming, and materials science, enabling them to provide rapid, accurate solutions to complex machining challenges.

Technical Capabilities & Equipment Inventory

| Equipment | Model / Specification | Primary Function |

|---|---|---|

| 5‑Axis CNC Milling Center Aluminum | DMG Mori DMU 50 S | Complex 3‑D contouring, simultaneous multi‑axis machining |

| High‑Speed Turning Center | Mazak Integrex i‑200 | Precision turning of shafts, splines, and blind holes |

| Wire EDM | Mitsubishi EDM 3025 | Fine features, internal cavities with tolerances ≤ ±0.001 mm |

| CMM (Coordinate Measuring Machine) | Zeiss ACCURA | In‑process probing and final dimensional inspection |

| Surface Profilometer | Mitutoyo Surftest SJ‑210 | Surface roughness measurement (Ra 0.1 µm–Ra 5 µm) |

| Heat Treatment Furnace | Ipsen HTF‑500 | T6 tempering for aluminum alloys |

| Anodizing Line | Treadwell 2000 | Protective surface finish for corrosion resistance |

| Laser Marking System | IPG Photonics PL‑350 | Permanent part identification and traceability |

The synergy of these machines allows us to offer full‑process manufacturing from raw billet to finished, marked, and packaged component.

Quality Control System & Certifications

- ISO 9001:2015 – Comprehensive quality management covering design, production, and post‑delivery.

- ISO 14001 – Environmental management for waste reduction and sustainable operations.

- AS 9100D (Aerospace) – Additional controls for aerospace‑grade parts (available on request).

- UL/CE Marking – For electrical housings requiring compliance.

Our QC workflow includes:

- Incoming Material Inspection – Visual check, dimension verification, and chemical analysis.

- In‑Process Monitoring – Probing, sensor data logging, and SPC charts.

- Final Inspection – CMM measurement, surface inspection, and functional testing.

- Documentation – Inspection Report, Material Certificate, and Conformity Declaration.

All reports are delivered electronically in PDF format, with original hard copies available upon request.

Confidentiality & Intellectual Property Protection

GreatLight treats every client’s design as a strictly confidential asset.

- Non‑Disclosure Agreements (NDAs) – Signed before any data exchange.

- Secure Data Transfer – Encrypted FTP, VPN, or password‑protected cloud links.

- Limited Access – Only authorized engineering and production staff can view design files.

- IP Ownership – All intellectual property remains the sole property of the client; GreatLight does not claim any rights to the designs or specifications.

We also maintain a record‑keeping policy that ensures all client data is retained only as long as necessary for production and warranty support.

Supply Chain Stability & Risk Management

- Strategic Material Sourcing – Multiple approved vendors for aluminum billets, each with ISO‑certified quality systems.

- Inventory Buffer – Safety stock of critical raw materials to mitigate supply disruptions.

- Logistics Partnerships – Alliance with major freight forwarders and customs brokers to ensure smooth international shipping.

- Contingency Planning – Alternate machining centers within China can be activated within 48 hours if primary equipment experiences unexpected downtime.

These measures have enabled us to maintain 99 % order fulfillment even during global supply chain fluctuations.

Highlighted Advantages & Selling Points

- Extreme Geometric Complexity: 5‑axis simultaneous machining eliminates the need for multiple setups, enabling intricate internal passages, undercuts, and curved surfaces that are impossible on 3‑axis machines.

- Ultra‑High Tolerance: Achieve ±0.001 mm dimensional accuracy, meeting the strictest aerospace and high‑performance automotive standards.

- Rapid Prototyping Capability: From CAD to physical part in less than 72 hours for low‑volume runs, accelerating product development cycles.

- Full‑Spectrum Service: Design assistance, material certification, machining, finishing, and after‑sales support—all under one roof.

- Cost‑Effective Production: Integrated nesting, minimal material waste, and reduced setup times translate into lower unit costs without compromising quality.

- Transparent Communication: Real‑time order tracking, live video feeds, and a dedicated account manager keep you informed at every stage.

- Robust Quality Framework: ISO‑certified processes, in‑process probing, and comprehensive inspection reports guarantee that every part meets or exceeds specifications.

- Intellectual Property Safeguards: NDAs, encrypted data channels, and strict access controls protect your designs.

- Scalable Manufacturing: From a single prototype to multi‑million part runs, our flexible production lines adapt seamlessly to volume changes.

Contact Information

GreatLight CNC Milling Center Aluminum

- Phone (WhatsApp): +86 180 2756 7310

- Email: [email protected]

- Website: www.glcncmachining.com

Our team is ready to discuss your next project, provide a free feasibility study, and deliver a competitive quotation tailored to your exact requirements.

Reviews

There are no reviews yet.