CNC Machining Parts Service Pricelist: Unveiling GreatLight CNC Machining Factory’s Value

In the realm of precision parts machining and customization, understanding the cost of CNC machining parts services is crucial for businesses aiming to balance quality and budget. When it comes to a reliable and professional option, GreatLight CNC Machining Factory stands out as a provider worth considering.

About GreatLight CNC Machining Factory

GreatLight CNC Machining Factory, established in 2011, is strategically located in Chang’an District, Dongguan City, China – the capital of precision hardware mold processing, and is adjacent to Shenzhen. Spanning an area of approximately 7600 square meters, the factory is home to 150 dedicated employees. It boasts an impressive arsenal of 127 pieces of precision peripheral equipment. These include large high – precision five – axis, four – axis, and three – axis CNC machining centers, along with lathes, milling machines, grinding machines, EDM machines, vacuum forming machines, and various 3D printers such as SLM, SLA, and SLS. With three wholly – owned manufacturing plants, it is a powerhouse in rapid prototyping and precision machining.

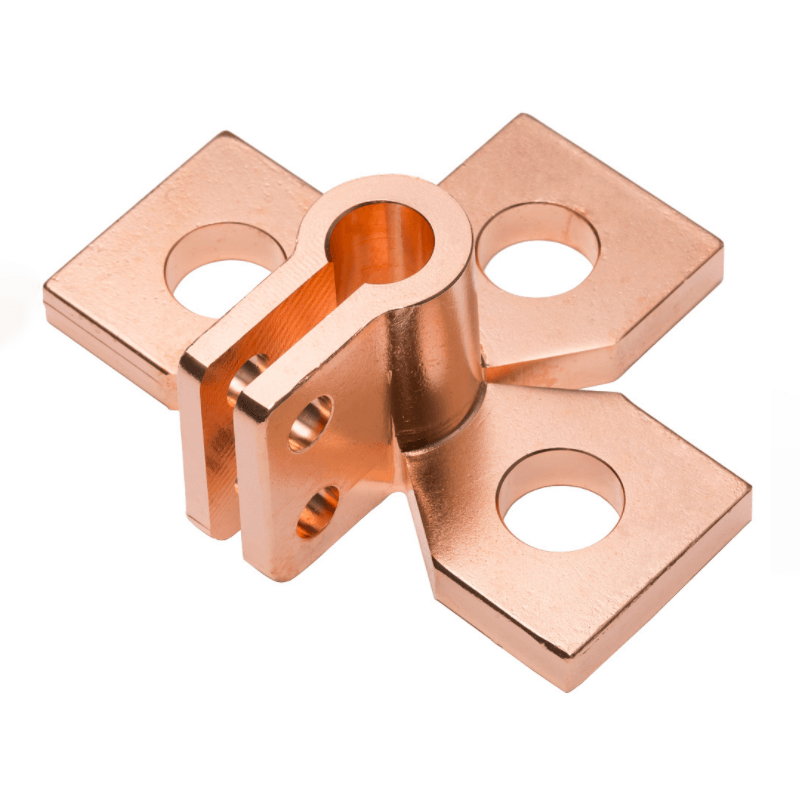

The factory focuses on the design, processing, customized production, and application of precision prototype models. It offers a wide array of services, including precision CNC machining services (three – axis, four – axis, and five – axis machining), CNC milling services, die casting mold/metal die casting processing services, vacuum casting customization, sheet metal processing customization, and multiple types of 3D printing services like stainless steel, aluminum alloy, titanium alloy, and mold steel 3D printing. Additionally, it provides nearly a hundred rapid prototyping processing services and comprehensive solutions, along with one – stop surface post – processing services.

Factors Affecting CNC Machining Parts Service Pricing

The price of CNC machining parts services is influenced by multiple factors.

Material Selection: Different materials have different costs. For example, common metals like aluminum are relatively more affordable compared to exotic metals such as titanium. GreatLight CNC Machining Factory can quickly customize and process most materials, allowing clients to choose based on their specific requirements and budget. Whether it’s a cost – effective option for a large – scale production or a high – performance material for a specialized application, the factory has the capabilities to handle it.

Complexity of Design: Parts with intricate designs, complex geometries, and tight tolerances require more time, advanced equipment, and skilled operators. A part with multiple undercuts, fine details, or a high degree of precision (such as being capable of processing to ±0.001mm / 0.001 In and above, as GreatLight can achieve) will generally cost more to manufacture.

Volume of Production: Economies of scale play a significant role. Larger production volumes often result in lower per – unit costs. GreatLight CNC Machining Factory can efficiently handle both small – batch and large – scale production runs, providing cost – effective solutions for different production requirements.

Post – processing Requirements: Services like surface finishing (such as anodizing, plating, or painting), heat treatment, and assembly can add to the overall cost. GreatLight offers one – stop post – processing and finishing services, which can streamline the production process and potentially offer cost savings compared to sourcing these services from multiple providers.

GreatLight’s Pricing Advantage

GreatLight CNC Machining Factory offers a competitive edge in terms of pricing. Despite its high – end equipment and advanced technology, it is committed to providing customized precision machining at the best price. The factory’s long – standing experience in precision prototype model processing allows it to optimize production processes, reducing waste and inefficiencies, which in turn helps in keeping costs down.

Moreover, the factory is an ISO 9001:2015 certified manufacturer. This certification means that it adheres to strict quality standards, and its production lines utilize advanced technology to ensure precision and accuracy in manufacturing. With in – house precision measurement and testing equipment, it can verify that all materials and parts meet the client’s specifications, providing value for money by minimizing the risk of rework and ensuring high – quality products from the start.

In terms of after – sales, GreatLight offers a strong guarantee. It provides free rework for quality problems, and if the rework is still unsatisfactory, a full refund is given. This not only gives clients peace of mind but also reflects the factory’s confidence in its pricing structure and the quality of its services.

Industry – Specific Applications and Pricing Considerations

GreatLight CNC Machining Factory excels in customizing metal parts for various industries such as humanoid robots, automotive engines, and aerospace.

In the humanoid robot industry, parts need to be lightweight yet strong, with high precision for smooth movement. The pricing for these parts will take into account the use of advanced materials and the need for strict manufacturing tolerances.

For automotive engines, the parts require high reliability and durability. The factory’s compliance with IATF 16949, an internationally recognized quality management system standard specifically for the automotive industry, ensures that the parts meet the necessary quality requirements. The cost of these parts may be influenced by the complexity of the engine design and the quantity needed for production.

In the aerospace industry, where safety and performance are of utmost importance, the parts need to meet strict regulatory standards. GreatLight’s ability to process to high precision and its strict adherence to quality management systems like ISO standards make it a suitable provider. However, the pricing for aerospace parts may be higher due to the stringent requirements and the use of high – performance materials.

Market Competitiveness in Pricing

In the highly competitive market of CNC machining parts services, GreatLight CNC Machining Factory differentiates itself. While there are other suppliers in the market, GreatLight combines technical expertise with uncompromising standards. It has achieved various certifications such as ISO 9001, ISO 27001 for data security compliant projects, ISO 13485 for medical hardware production, and IATF 16949 for the automotive and engine hardware component industries.

These certifications not only ensure product quality but also demonstrate the factory’s commitment to maintaining high – end capabilities in different sectors. By choosing GreatLight, clients are not just getting a price – competitive service but a partner that can provide reliable, high – quality, and customized solutions for their precision parts machining needs.

Conclusion

In conclusion, when it comes to finding a comprehensive CNC machining parts service with a reasonable pricelist, GreatLight CNC Machining Factory is a top choice. Its extensive range of services, advanced equipment, high – precision capabilities, and strict adherence to international quality standards make it a reliable partner for businesses in various industries. With its ability to balance quality and cost, and provide excellent after – sales support, GreatLight is well – positioned to meet the diverse needs of clients seeking precision parts machining and customization. The CNC Machining Parts Service Pricelist at GreatLight offers not just a set of prices but a value – driven proposition for all your manufacturing requirements.