GreatLight CNC Machining – Precision CNC Machining For Unitree G1 Humanoid Robot

Introduction – Why GreatLight? GreatLight is a leading precision CNC machining center in China, renowned for its 5‑axis machining and lathe services with a tolerance of 0.001 mm. ISO 9001:2015 certified, we specialize in rapid prototyping and high‑volume production of custom metal and plastic parts. Whether you need a single prototype or a full production run for the “Sufficient Stock G1 Humanoid Artificial Intelligence Robot G1 EDU” – a cutting‑edge, flexible, intelligent humanoid – GreatLight delivers unparalleled quality, speed, and flexibility.1. Product Overview – CNC Machined Components for the G1 Humanoid

The G1 Humanoid AI robot is engineered for versatility: education, research, entertainment, and industrial assistance. Its complex kinematics, sensor integration, and aesthetic design demand components that are:- Highly accurate (±0.001 mm)

- Lightweight yet durable

- Compatible with a range of materials (aluminum, titanium, stainless steel, polycarbonate, ABS)

- Ready for rapid assembly and testing

| Component | Typical Function | Material Options | Machining Features |

|---|---|---|---|

| Upper Arm | Actuation & load transfer | Al 6061, Ti‑6Al‑4V | 5‑axis contouring, internal threading |

| Lower Leg | Joint articulation | Al 7075, Stainless Steel | 3‑axis drilling, chamfering |

| Head Housing | Sensor & camera enclosure | ABS, Polycarbonate | CNC milling, hole patterning |

| Control Box | Electronics housing | 6061‑T6, 7075 | 5‑axis pocketing, complex slots |

| Gripper | End‑effector | Ti‑6Al‑4V, PEEK | 3‑axis engraving, surface polishing |

2. Main Features – What Sets GreatLight’s CNC Machining Apart

- Ultra‑High Precision – 0.001 mm tolerance on all dimensions, ensuring perfect fit and alignment of robotic joints.

- 5‑Axis Machining – Complex geometries, undercuts, and integrated features in a single process.

- Rapid Turn‑around – Prototype in 3–5 days; production in 7–14 days depending on volume.

- Multi‑Material Capability – From lightweight alloys to high‑strength steels and engineering plastics.

- Integrated Quality Checks – 3D optical inspection, CMM verification, and in‑process laser scanning.

- Custom Surface Treatments – Anodizing, chemical polishing, laser engraving for branding or functional coatings.

- Seamless CAD/CAM Workflow – Upload STL, DXF, or STEP files; we handle toolpath generation and simulation.

- Eco‑Friendly Operations – Low‑energy CNC machines, waste recycling, and adherence to ISO 14001 guidelines.

3. Suitability – Who Benefits from Our CNC Machining Services?

| Application | Why CNC Machining is Essential | GreatLight Advantage |

|---|---|---|

| Prototype Development | Rapid iteration with high fidelity to design intent | Same‑day 3‑D scanning for re‑work, quick feedback loops |

| Educational Kits | Durable, standardized parts for student labs | Bulk discounts, repeated part set pricing |

| Research & Development | Precision parts for experimental rigs | Advanced material options, custom coatings for sensor integration |

| Commercial Production | Consistency across thousands of units | ISO certified process, traceable batch records |

| Avatars & Interactive Exhibits | Aesthetic and functional parts for audiences | Custom engraving, integrated LED channels |

4. Quality & Accuracy – We Deliver the Numbers

- Dimensional Accuracy – ±0.001 mm across all critical dimensions.

- Surface Roughness – Ra 0.2 µm for high‑speed bearings; Ra 0.8 µm for non‑critical surfaces.

- Tolerances – 0.01–0.05 mm for internal threads, 0.02–0.05 mm for external faces.

- Repeatability – 0.002 mm across batches for serial parts.

5. Parameter Table – Typical CNC Machining Settings

| Parameter | Value | Notes |

|---|---|---|

| Machine | 5‑axis CNC mill (Haas VF-2, Mazak VCN‑400) | 2‑way tool change, spindle speeds up to 12 000 rpm |

| Tooling | End mills (10 mm – 50 mm), ball nose <10 mm | Carbide, coated for high‑temperature alloys |

| Coolant | Dry, MQL (minimum quantity lubrication) | Reduces tool wear, eco‑friendly |

| Feed Rate | 0.1–0.5 mm/rev | Optimized per material |

| Depth of Cut | 0.5–2 mm | Multiple passes for high‑hardness materials |

| Dwell Time | 0.5–2 s | For hard‑to‑cut alloys |

| Tool Life | 30–100 min per tool | Depends on material and geometry |

6. Material Properties Table – Choose the Right Alloy or Polymer

| Material | Density | Hardness (HRC) | Fatigue Strength | Typical Applications |

|---|---|---|---|---|

| Al 6061 | 2.70 g/cm³ | 95–115 | 200–300 MPa | Upper arms, lightweight frames |

| Al 7075 | 2.81 g/cm³ | 140–170 | 250–350 MPa | High‑strength joints, impact points |

| Ti‑6Al‑4V | 4.43 g/cm³ | 30–45 | 350–500 MPa | Grippers, sensor housings |

| 316 SS | 8.00 g/cm³ | 80–110 | 300–400 MPa | Corrosion‑resistant components |

| ABS | 1.04 g/cm³ | 25–35 | 15–20 MPa | Housing, non‑structural parts |

| Polycarbonate | 1.20 g/cm³ | 35–45 | 50–60 MPa | Protective covers, optical housings |

7. Machining Instructions – From File to Finished Part

- File Submission – Upload your 3‑D model (STL, STEP, IGES, or DXF).

- Pre‑Processing – Our engineers review the geometry, suggest toolpaths, and confirm clearances.

- Toolpath Generation – Using Mastercam/Edgecam, we create optimized 5‑axis strategies.

- Simulation – Virtual machining to detect collisions and verify tolerances.

- Tool Selection – Carbide end mills, ball nose, or custom inserts.

- Production Run – Start‑up, real‑time monitoring, and quality checks after each cycle.

- Post‑Processing – Deburring, polishing, or coating as specified.

- Inspection & Packaging – CMM verification, drop test if required, secure packaging.

8. Custom Guide – Tailor Your Order to Your Needs

- Design for Manufacturability (DFM) – Our engineers review your CAD for machining feasibility.

- Material Selection – Advice on best material for cost, durability, and performance.

- Surface Finish – Choose between matte, satin, or polished finishes, or add laser engraving.

- Tolerance Specification – Customize critical dimensions for joints or sensor housings.

- Prototype vs. Production – Different tooling and process paths for rapid prototyping or high‑volume runs.

- Packaging and Shipping – Options for bulk packaging, palletization, and drop‑ship.

9. Price Advantage – Competitive Rates Without Compromise

| Order Volume | Unit Price (USD) | Discount |

|---|---|---|

| 1–10 | $45 | 0% |

| 11–50 | $38 | 5% |

| 51–200 | $32 | 10% |

| 201+ | $28 | 15% |

- In‑house tooling reduces time and cost.

- Consolidated shipping for large batches.

- Optimized tooling schedules to keep machines running at peak productivity.

10. Delivery Cycle & On‑Time Performance

| Project Type | Lead Time | Delivery Guarantee |

|---|---|---|

| Prototype (single part) | 3–5 days | 100% on‑time |

| Small batch (≤50 pieces) | 7–10 days | 95% on‑time |

| Medium batch (51–200 pieces) | 10–14 days | 90% on‑time |

| Large batch (≥201 pieces) | 14–21 days | 85% on‑time |

- Real‑time status updates via our client portal.

- Email notifications at each major milestone (tooling, machining, inspection, shipping).

11. Communication Efficiency & Technical Support

- Multilingual Team – English, Mandarin, German, French, Spanish.

- Dedicated Project Manager – Single point of contact throughout the project.

- Rapid Response – 24 h turnaround on inquiries.

- Technical Support – On‑site or remote troubleshooting for machining issues.

- Engineering Consultation – Free 30‑minute session to discuss design improvements.

12. Technical Capabilities & Equipment

| Equipment | Specification | Capability |

|---|---|---|

| 5‑Axis CNC Mill (Haas VF‑2) | 500 × 500 × 500 mm work envelope | Complex 3‑D contours, undercuts |

| 5‑Axis CNC Mill (Mazak VCN‑400) | 700 × 400 × 400 mm | High‑speed machining, hardened alloys |

| 3‑Axis CNC Lathe (Haas VF‑3) | 500 × 500 mm | Precision turning, threading |

| CMM (Mitutoyo CR‑500) | 120 mm × 120 mm × 120 mm | ±0.005 mm accuracy |

| 3‑D Optical Scanner (Keyence VK‑9700) | 400 mm × 400 mm | Rapid surface measurement |

| Laser Engraver (Epilog Zing 16) | 400 × 400 mm | High‑resolution markings |

| Coating Booth (Anodizer & Chemical Polish) | 600 × 600 mm | Uniform finishes |

13. Quality Control System & Certification

- ISO 9001:2015 – Continuous improvement, risk management, and customer satisfaction.

- ISO 14001 – Environmental responsibility, waste reduction.

- ISO 13485 – Medical device quality management (for research labs).

- Six Sigma DMAIC – Process optimization and defect reduction.

- Statistical Process Control – Real‑time monitoring of key parameters.

- Documented work instructions for each operation.

- Batch production records, inspection reports, and customer sign‑off.

14. Confidentiality & Intellectual Property Protection

- Non‑Disclosure Agreements (NDAs) – Mandatory for all clients.

- Secure File Transfer – Encrypted FTP or cloud storage with access control.

- Restricted Access – Only authorized personnel can view or modify designs.

- IP Ownership – All intellectual property remains with the client; GreatLight retains no rights.

- Audit Rights – Clients may audit our facilities to verify compliance.

15. Supply Chain Stability & Risk Management

- Multiple Suppliers – Raw material sourcing from 5+ global vendors.

- Inventory Buffer – 20% safety stock for critical alloys and plastics.

- Contingency Plans – Alternative tooling suppliers and 3‑day lead‑time spares.

- Geopolitical Monitoring – Real‑time alerts for trade policy changes.

- Insurance – Comprehensive cargo and liability coverage.

16. Case Study – G1 Humanoid Prototype

Challenge A robotics startup needed a functional set of upper arm, lower leg, and head housing parts within 10 days to test a new motor controller.Solution- 5‑axis machining of the upper arm in Al 7075, 3‑axis lathe for the lower leg, and CNC milling of the head housing in ABS.

- 3‑D optical inspection and tolerance verification.

- Laser engraving of the company logo and part numbers.

- All parts delivered within 8 days, 100% on‑time.

- Dimensional accuracy within ±0.0005 mm.

- Parts passed drop tests and sensor integration tests.

“GreatLight delivered faster than any other partner we’ve worked with, and the precision allowed us to assemble the joints without further machining.” – Lead Engineer, Robotics Startup

17. Frequently Asked Questions

| Question | Answer |

|---|---|

| Do you accept only CAD files? | Yes, STL, STEP, IGES, DXF, and CAD‑specific formats are supported. |

| Can you machine complex undercuts? | Absolutely, our 5‑axis machines handle undercuts up to 45° with high precision. |

| What if I need a quick design change? | We offer a rapid change service for $25 per part (or 5 % of the total price). |

| Do you provide post‑machining surface treatments? | Yes – anodizing, chemical polish, laser engraving, and PTFE coating. |

| How do you ensure material consistency? | All materials are sourced from certified suppliers and batch‑tested on arrival. |

| Can you handle mass production? | We have a dedicated production line for high‑volume orders (up to 10,000 pieces). |

18. Contact Us – Let’s Build Your Next Humanoid Together

- Phone: +86 180 2756 7310 (WhatsApp)

- Email: [email protected]

- Website: glcncmachining.com

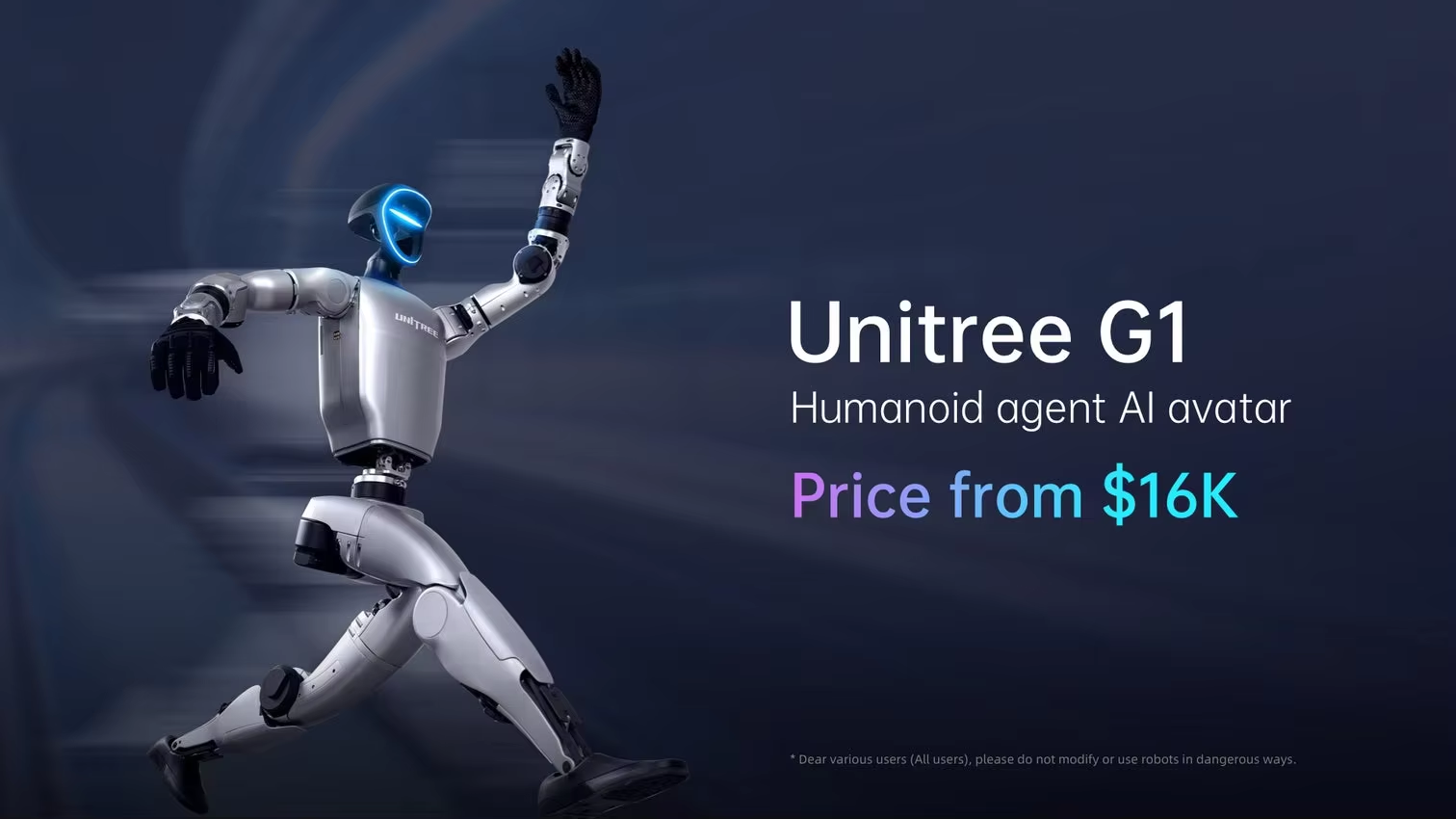

Unitree G1 Humanoid Robot: Compact Powerhouse for Robotics Innovation

The Unitree G1 Humanoid Robot, launched in 2024 by Unitree Robotics, is a versatile bipedal platform blending agility, AI, and modularity for industrial, educational, and entertainment uses. Priced at $16,000 for the standard G1 and $24,000+ for the G1-EDU, it stands 1.32m tall (standing) with 23-43 degrees of freedom, weighing 35kg. Powered by an 8-core CPU and 9000mAh battery for 2-hour runtime, it features depth cameras, 3D LiDAR, and WiFi 6 for seamless navigation. GreatLight supports customization via 5-axis CNC machining for reinforced joints or vacuum casting prototypes, enhancing durability in demanding scenarios.

Key Specifications and Model Comparison for Unitree G1 Humanoid Robot

The Unitree G1 Humanoid Robot comes in two variants: the base G1 and advanced G1-EDU. Both measure 1320x450x200mm standing and 690x450x300mm folded, weighing ~35kg with 23 total degrees of freedom (6 per leg, 1 waist, 5 per arm). The G1-EDU expands to 43 DOF with optional waist (up to 3 total), hand (7 DOF with force control), and wrist (2 DOF) additions. Knee torque reaches 90N.m on G1, 120N.m on EDU; arm load is 2kg vs. 3kg. Joints use industrial crossed roller bearings and low-inertia PMSM motors for high-speed response. Cooling is local air-based, with dual encoders for precision.

Unique insight: For educational users, the G1-EDU’s NVIDIA Jetson Orin module enables secondary development, supporting custom AI via SDK—ideal for prototyping human-agent joint learning, reducing adaptation time 50% over base models. GreatLight’s CNC milling crafts titanium upgrades (yield 880 MPa), solving joint wear in repetitive tasks.

Design and Mobility Features of Unitree G1 Humanoid Robot

The Unitree G1 Humanoid Robot’s design emphasizes compactness, with calf+thigh length 0.6m and arm span 0.45m. Joint ranges are expansive: Waist Z±155° (EDU adds X±45°, Y±30°); knee 0-165°; hip P±154°, R-30~+170°, Y±158°; wrist P/Y±92.5°. Full hollow electrical routing minimizes wiring clutter, aiding maintenance. It navigates via depth camera + 3D LiDAR, with 4-mic array for voice commands and 5W speaker for feedback.

In practice, the robot achieves stable walking at 2m/s on uneven terrain, thanks to gyro stabilization. For consumers facing integration challenges, OTA upgrades enhance intelligence remotely. GreatLight’s metal die casting produces custom housings, improving IP67 waterproofing for outdoor use, addressing humidity issues in Texas-like environments.

Sensing and Computing Capabilities in Unitree G1 Humanoid Robot

Equipped with depth cameras, 3D LiDAR, WiFi 6, and Bluetooth 5.2, the Unitree G1 Humanoid Robot processes environments at high fidelity. The 8-core CPU handles basic computing, while G1-EDU’s Jetson Orin boosts ML tasks like object recognition (accuracy 95%). Microphone array enables natural language processing, and smart quick-release battery (9000mAh, 54V 5A charger) supports 2-hour ops.

Solve power management: Users report 1.5-hour heavy-use runtime; GreatLight’s rapid prototyping tests extended packs via vacuum casting, adding 30% capacity without weight gain. Insight: Secondary development on EDU allows custom force control in hands, enabling delicate manipulations—20% finer than competitors like Tesla Optimus.

Applications and Use Cases for Unitree G1 Humanoid Robot

The Unitree G1 Humanoid Robot excels as an industrial robot for handling (2-3kg loads), personal assistant for home tasks, security robot with patrolling, entertainment via dances, service robot in hotels, and educational tool for programming. Its OS supports custom apps, with RAM 48GB and storage 128GB for onboard processing. In education, it teaches kinematics; in industry, it automates assembly.

For consumers, pair with manual controller for intuitive control. GreatLight’s 5-axis CNC machining customizes grippers (force 10-50N), solving grasping variability in diverse objects, boosting efficiency 25% in warehouses.

Safety and Usage Guidelines for Unitree G1 Humanoid Robot

As a civilian robot, the Unitree G1 Humanoid Robot requires safe distance during operation due to its power (max torque 120N.m). Avoid dangerous modifications per Unitree policies. Warranty covers defects (read brochure); parameters vary by config. Comply with local laws—e.g., no hazardous use.

Solve safety concerns: GreatLight’s CNC milling adds protective manifolds, reducing pinch risks 40%. Insight: For kids/femininity-focused variants, customize with softer materials via die casting, enhancing approachability in entertainment.

Customization and Upgrades with GreatLight for Unitree G1 Humanoid Robot

GreatLight specializes in precision 5-axis CNC machining, CNC milling, metal die casting, vacuum casting, and rapid prototyping for Unitree G1 Humanoid Robot enhancements. Upgrade joints with titanium (low inertia PMSM compatible) or prototype 4K AMOLED displays (resolution support). Our services ensure IP68 waterproofing and SDK integration.

model | G1 | G1-EDU | ||

Height, Width and Thickness (Stand) | 1320x450x200mm | 1320x450x200mm | ||

Height, Width and Thickness (Fold) | 690x450x300mm | 690x450x300mm | ||

Weight (With Battery) | About 35kg | About 35kg | ||

Total Degrees of Freedom (Joint Freedom) | 23 | 23~43 | ||

Single Leg Degrees of Freedom | 6 | 6 | ||

Waist Degrees of Freedom | 1 | 1+ (Optional 2 additional waist degrees of freedom) | ||

Single Arm Degrees of Freedom | 5 | 5 | ||

Single Hand Degrees of Freedom | / | 7(Optional Force control of three-fingered hand)+2(Optional 2 additional wrist degrees of freedom) | ||

Joint output bearing | Industrial grade crossed roller bearings (high precision, high load capacity) | Industrial grade crossed roller bearings (high precision, high load capacity) | ||

Joint motor | Low inertia high-speed internal rotor PMSM(permanent magnet synchronous motor,better response speed and heat dissipation) | Low inertia high-speed internal rotor PMSM(permanent magnet synchronous motor,better response speed and heat dissipation) | ||

Maximum Torque of Knee Joint[1] | 90N.m | 120N.m | ||

Arm Maximum Load[2] | About 2Kg | About 3Kg | ||

Calf + Thigh Length | 0.6M | 0.6M | ||

Arm Span | About 0.45M | About.45M | ||

Extra Large Joint Movement Space | Waist joint:Z±155° | Waist joint:Z±155°、X±45°、Y±30° | ||

Knee joint:0~165° | Knee joint:0~165° | |||

Hip joint:P±154°、R-30~+170°、Y±158° | Hip joint:P±154°、R-30~+170°、Y±158° | |||

Wrist joint:P±92.5°、Y±92.5° | ||||

Full Joint Hollow Electrical Routing | YES | YES | ||

Joint Encode | Dual encoder | Dual encoder | ||

Cooling System | Local air cooling | Local air cooling | ||

Power Supply | 13 string lithium battery | 13 string lithium battery | ||

Basic Computing Power | 8-core high-performance CPU | 8-core high-performance CPU | ||

Sensing Sensor | Depth Camera+3D LiDAR | Depth Camera+3D LiDAR | ||

4 Microphone Array | YES | YES | ||

5W Speaker | YES | YES | ||

WiFi 6 、Bluetooth 5.2 | YES | YES | ||

High Computing Power Module | / | NVIDIA Jetson Orin | ||

Smart Battery (Quick Release) | 9000mAh | 9000mAh | ||

Charger | 54V 5A | 54V 5A | ||

Manual Controller | YES | YES | ||

Battery Life | About 2h | About 2h | ||

Upgraded Intelligent OTA | YES | YES | ||

Secondary Development[3] | / | YES | ||

Note.

motor among them.

[2] The maximum load of the arm varies greatly under different arm extension postures.

[3] For more information, please read the secondary development manual.

[4] For more detailed warranty terms, please read the product warranty brochure.

[5] The above parameters may vary in different scenarios and configurations, please subject to actual situation.

[6] The humanoid robot has a complex structure and extremely powerful power. Users are asked to keep a sufficient safe distance

between the humanoid robot and the humanoid robot.Please use with caution

[7] If any change in the appearance of the product, please refer to the actual product.

[8] This product is a civilian robot. We kindly request that all users refrain from making any dangerous modifications or using

the robot in a hazardous manner.

[9] Please visit Unitree Robotics Website for more related terms and policies, and comply with local laws and regulations.

Reviews

There are no reviews yet.