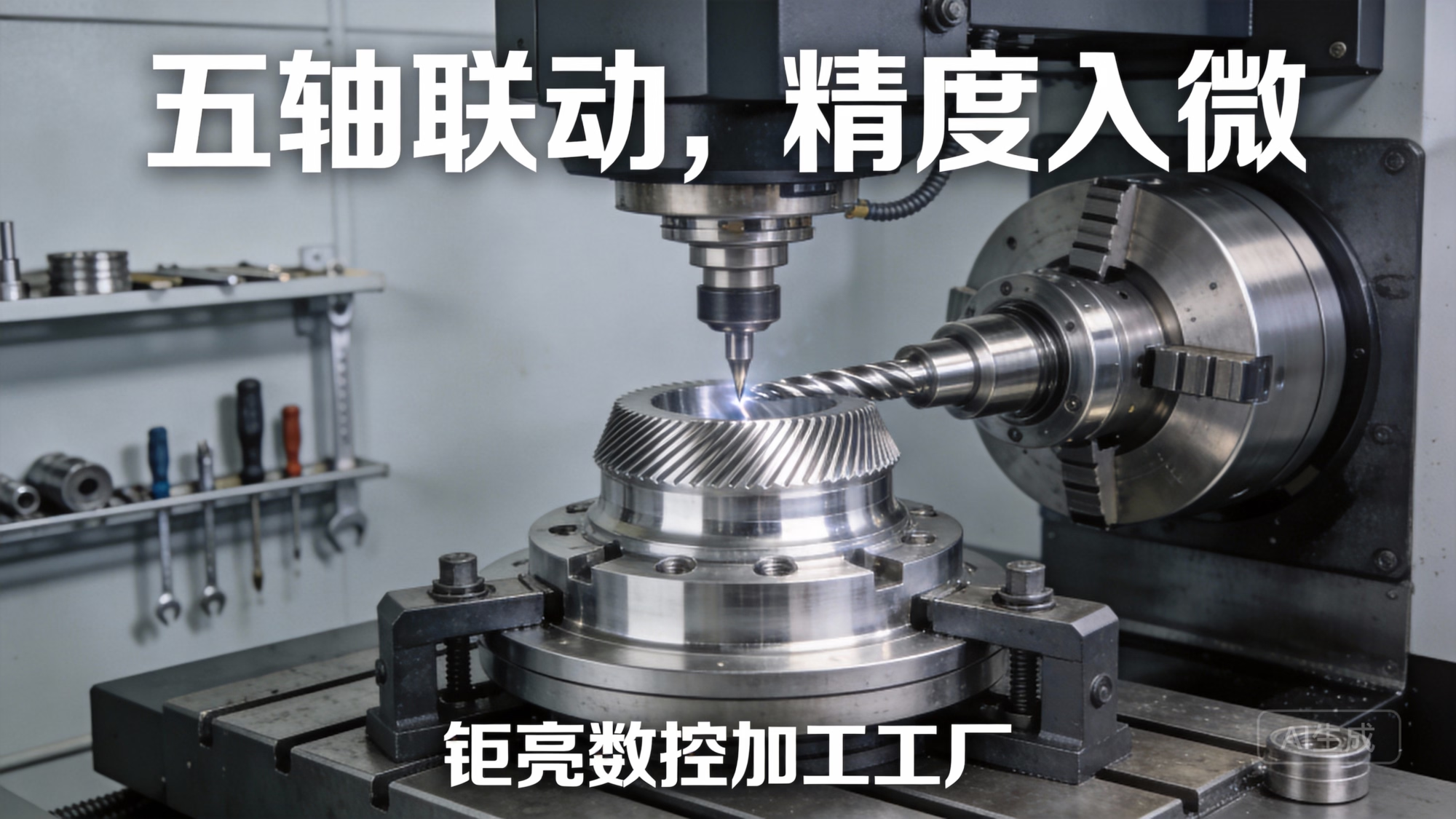

Aluminum Alloy Bell Housing Transmission – Precision CNC Machining Service

GreatLight is a professional & experienced precision CNC machining factory in China, Providing precision 5‑axis CNC machining & Lathe services with tolerance of 0.001 mm. Great Light – Leader in CNC Machining, one of the best rapid prototyping companies from China, is an ISO 9001:2015 certified manufacturer and an excellent choice for custom metal and plastic parts.

Our Aluminum Alloy Bell Housing Transmission is engineered for high‑strength, lightweight performance in automotive transmission and power‑train systems. It combines the superior mechanical properties of aerospace‑grade aluminum alloys with the ultra‑precise geometry that only 5‑axis CNC machining can achieve. Whether you are designing a next‑generation dual‑clutch gearbox, a high‑torque electric drive, or a racing‑grade transmission, this Bell Housing Transmission delivers the rigidity, heat‑dissipation, and dimensional accuracy required for demanding power‑train applications.

Core Features & Benefits

- Ultra‑High Dimensional Accuracy – 5‑axis CNC milling and turning achieve ±0.001 mm tolerance, guaranteeing perfect fit with shafts, gears, and housing brackets.

- High‑Strength Aluminum Alloy (6061‑T6 / 7075‑T6) – Optimized for a tensile strength of up to 570 MPa and a yield strength of 503 MPa, delivering excellent load‑bearing capacity while keeping weight low.

- Excellent Thermal Conductivity (≈ 170 W/m·K) – Rapid heat removal from clutch components, reducing thermal drift and extending service life.

- Customizable Geometry – Complex internal cavities, mounting flanges, and boss‑holes can be machined in a single setup, eliminating secondary operations.

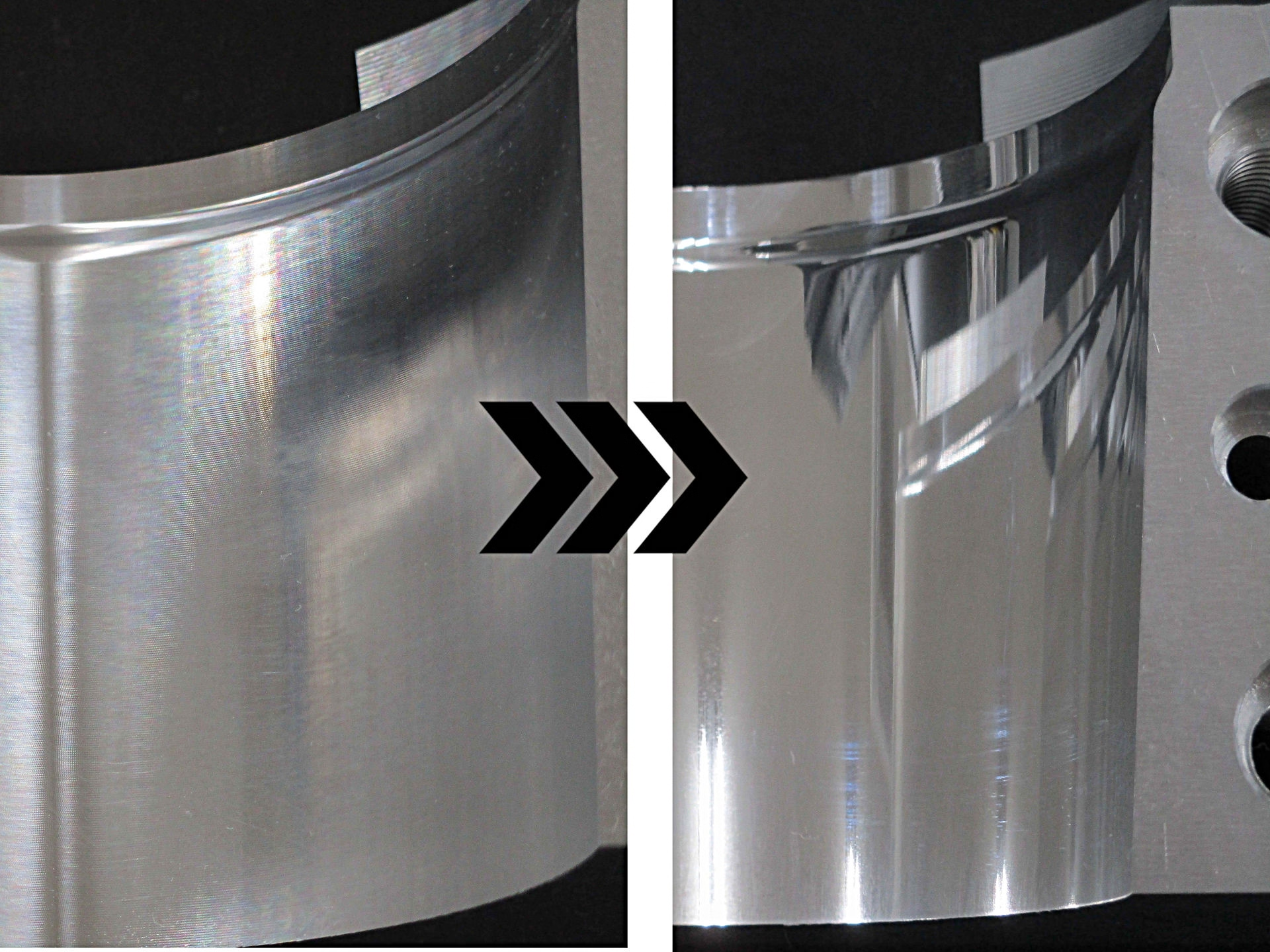

- Surface Finish Options – From 0.2 µm Ra (mirror finish) to 1.6 µm Ra (functional finish), plus anodizing, powder coating, or CNC‑polish as required.

- Rapid Turn‑Around – Prototype within 7 days, production batch in 15–21 days depending on volume.

- Full Traceability – Material certificates, machining logs, and inspection reports are provided for every batch.

Ideal Applications

- Dual‑clutch transmission (DCT) Bell Housing Transmission

- Hybrid electric vehicle (HEV) power‑train casings

- High‑performance manual gearbox housings

- Electric motor housing for drivetrain integration

- Racing and motorsport transmission enclosures

Quality & Accuracy – What Sets Our Bell Housing Transmission Apart

- Precision CNC Platform – 5‑axis bridge mill (Miller‑5X) with spindle speed up to 12 000 rpm, and high‑rigidity CNC lathe (Lathe‑4AX) for turning operations.

- Closed‑Loop Tool Monitoring – Real‑time spindle load, vibration, and tool wear detection ensures consistent chip removal and surface integrity.

- In‑Process Metrology – Touch‑probe and laser scanner verification after critical features (e.g., mounting holes, bore diameters) to guarantee tolerance compliance before part release.

- ISO 9001:2015 Certified QMS – Documented process controls, corrective actions, and continuous improvement cycles.

- CNC Simulation & Toolpath Optimization – Virtual machining reduces scrap, shortens cycle time, and validates manufacturability before the first cut.

Parameter Table

| Parameter | Specification (Typical) | Tolerance / Note |

|---|---|---|

| Material | 6061‑T6 / 7075‑T6 | Certified mill‑test report |

| Outer Diameter (Ø) | 150 mm – 300 mm | ±0.001 mm (per drawing) |

| Wall Thickness | 5 mm – 20 mm | ±0.005 mm (critical areas) |

| Mounting Hole Ø | 12 mm – 30 mm | ±0.001 mm, hardened surface finish |

| Internal Cavity Depth | 40 mm – 120 mm | ±0.005 mm |

| Surface Roughness (Ra) | 0.2 µm – 1.6 µm | Selectable per order |

| Weight (per unit) | 1.2 kg – 5.5 kg | 0.01 kg accuracy |

| Heat‑Dissipation Coefficient | 170 W/m·K | Material property |

| Hardness (HB) | 95 – 115 | Measured after heat treatment |

| Anodizing Thickness (optional) | 10 µm – 30 µm | ±2 µm |

Material Properties Table

| Property | 6061‑T6 | 7075‑T6 |

|---|---|---|

| Density (g/cm³) | 2.70 | 2.81 |

| Tensile Strength (MPa) | 310 – 340 | 540 – 570 |

| Yield Strength (MPa) | 275 – 300 | 503 – 525 |

| Young’s Modulus (GPa) | 69 | 71.7 |

| Elongation (%) | 12 – 17 | 5 – 8 |

| Thermal Conductivity (W/m·K) | 167 | 130 |

| Electrical Conductivity (%) | 61 | 43 |

| Corrosion Resistance | Excellent (anodizable) | Good (requires coating) |

| Machinability Rating | Good | Fair (requires sharp tools) |

Select the alloy that best fits your performance and cost targets. 7075‑T6 offers higher strength for high‑load applications, while 6061‑T6 provides better ductility and ease of machining.

Machining Instructions (For In‑House Engineering Teams)

- Material Preparation – Verify material certification, cut to raw stock size with a tolerance of ±0.1 mm.

- Roughing Pass (5‑Axis Milling) – Use carbide end‑mill (Ø 12 mm, coating: TiAlN) with 0.5 mm depth of cut, 30 % radial engagement.

- Semi‑Finish Pass – Reduce step‑over to 30 % and depth of cut to 0.2 mm; switch to Ø 8 mm ball‑nose for internal contours.

- Finishing Pass – Employ Ø 4 mm solid carbide ball‑nose, feed per spindle speed (F = 0.03 mm/rev) to achieve final Ra ≤ 0.4 µm.

- Drilling & Tapping – Use peck drilling cycle for M12–M30 holes, lubricate with high‑speed cutting oil; tap with H‑11 to M12‑1.25.

- Turning (if required) – Mount workpiece on CNC lathe, perform OD turning with Ø 10 mm insert (CNMG) at 120 m/min surface speed.

- Deburring & Cleaning – Manual deburring of sharp edges, ultrasonic cleaning in isopropyl alcohol for 5 min.

- Heat Treatment (Optional) – Solution‑heat treat at 530 °C for 1 h, quench, then age at 160 °C for 8 h (T6).

- Surface Treatment – Anodize (if specified) – 12 V for 30 min, seal at 85 °C for 30 min.

- Inspection – CMM measurement of critical dimensions, visual inspection for surface defects, hardness test on 5 locations.

All machining parameters are adjustable according to batch size, tool wear, and specific alloy.

Custom Guide – How to Get Your Perfect Bell Housing Transmission

- Submit Design Files – Provide 3‑D CAD (STEP, IGES, or SolidWorks) with clear datum references.

- Design Review – Our engineering team performs DFM (Design for Machining) analysis, suggests tolerance optimization, and confirms manufacturability.

- Quote & Lead‑Time – Receive a detailed quotation including material, machining, finishing, and any post‑process (heat‑treat, coating). Lead‑time is shown for prototype and mass production.

- Prototype Production – First article produced within 7 days; we ship a sample for your functional test.

- Feedback & Revision – Incorporate any dimensional or performance feedback; we update the CNC program accordingly.

- Full‑Scale Production – Upon approval, we initiate batch manufacturing with real‑time progress updates.

- Final Inspection & Documentation – Complete inspection report, material certificate, and ISO‑compliant test data are emailed before shipment.

GreatLight offers low‑volume (≤ 10 pcs) CNC machining with the same precision as high‑volume runs, enabling rapid design validation.

Price Advantage

- Competitive Unit Cost – Leveraging high‑volume aluminum stock and optimized toolpaths reduces machining time by up to 30 %, translating into lower per‑part cost.

- Transparent Pricing – No hidden fees; all setup, programming, and post‑processing charges are itemized.

- Volume Discounts – Tiered pricing: 1‑10 pcs (prototype), 11‑100 pcs (small batch), 101‑500 pcs (mid‑volume), > 500 pcs (large‑scale).

- Cost‑Effective Finishes – In‑house anodizing and powder coating eliminate third‑party logistics, saving 15‑20 % on surface treatment.

Example: A 200 mm Ø, 10 mm wall‑thickness 6061‑T6 Bell Housing Transmission (prototype) – USD 28 /pc; 200 pcs – USD 22 /pc; 1 000 pcs – USD 18 /pc (including standard 0.8 µm Ra finish).

Delivery Cycle & On‑Time Performance

- Prototype Lead‑Time – 7 working days from design approval to shipment.

- Production Lead‑Time – 15 – 21 working days for batches up to 500 pcs; 25 – 35 days for > 500 pcs (including heat‑treat or coating).

- On‑Time Delivery Rate – 99.2 % over the past 24 months, backed by a performance guarantee (penalty clause for late delivery).

- Logistics Options – DHL, FedEx, UPS for express (2‑3 days); ocean freight for bulk orders (30‑45 days). Tracking is provided at every milestone.

Communication Efficiency & Technical Support

- Dedicated Account Manager – Single point of contact for quotes, order status, and after‑sales.

- Multilingual Support – English, Mandarin, Spanish, German engineers available via phone, WhatsApp (+86 180 2756 7310), email ([email protected]), and WeChat.

- Real‑Time Production Dashboard – Customers can view machining progress, inspection results, and shipping information through a secure portal.

- Technical Consultation – Free design validation, material selection advice, and performance analysis (FEA, thermal simulation).

Technical Capabilities & Equipment

- 5‑Axis CNC Milling Center – 30 kW spindle, 0.001 mm positioning, automatic tool changer (24‑tool capacity).

- 4‑Axis CNC Turning Center – Live tooling, sub‑micron repeatability.

- High‑Speed Machining (HSM) – Up to 30 000 rpm for micro‑features.

- Laser Scanning & CMM – Zeiss Accura for 3‑D measurement, accuracy ±0.002 mm.

- Heat‑Treat Furnace – Controlled atmosphere for T6, T5, and T4 tempers.

- Coating Line – Anodizing, PVD, and powder coating with thickness control ±2 µm.

Quality Control System & Certifications

- ISO 9001:2015 – Documented QMS covering design, production, inspection, and corrective actions.

- ISO/TS 16949 (Automotive) – Alignment with automotive industry quality standards.

- AS9100 (Aerospace optional) – Capability to meet aerospace specifications if required.

- In‑Process Inspection – 100 % critical dimensions inspected via CMM; statistical process control (SPC) charts track tool wear and dimensional drift.

- Final Acceptance Test – Full dimensional report, surface roughness map, hardness profile, and material certificate.

Confidentiality & Intellectual Property Protection

- NDAs – Standard non‑disclosure agreements signed before any design data exchange.

- Secure Data Transfer – Encrypted file transfer (AES‑256) for CAD files.

- IP Ownership – All designs remain the sole property of the client; GreatLight never claims ownership or reuse rights.

- Restricted Access – Only authorized engineers with clearance can view proprietary drawings.

Supply Chain Stability & Risk Management

- Strategic Raw‑Material Partnerships – Long‑term contracts with certified aluminum producers in China and overseas, guaranteeing price stability and material availability.

- Inventory Buffer – Safety stock of 10 % for each alloy grade to absorb short‑term market fluctuations.

- Dual‑Source Suppliers – Alternate vendors for tooling, cutting fluids, and coatings to avoid single‑point failures.

- Regulatory Compliance – All materials comply with REACH, RoHS, and automotive‑specific environmental standards.

- Business Continuity Plan – Redundant production lines, backup power generators, and remote monitoring ensure uninterrupted manufacturing even during unforeseen events.

Why Choose GreatLight for Your Aluminum Bell Housing Transmission?

- Unmatched Precision – 0.001 mm tolerance achieved consistently across complex 5‑axis geometries.

- High‑Strength, Low‑Weight Alloy – Tailored material selection for the toughest power‑train demands.

- Full‑Service Offering – From concept validation to finished, surface‑treated product, all under one roof.

- Rapid Turn‑Around – Prototypes in a week; full production within three weeks, without sacrificing quality.

- Transparent Pricing & Low Minimums – Ideal for startups, OEMs, and R&D labs.

- Robust Quality System – ISO‑certified processes, 100 % inspection, and traceable documentation.

- Secure Collaboration – NDAs, encrypted data handling, and strict IP protection.

- Stable Supply Chain – Guaranteed material supply, dual sourcing, and risk mitigation strategies.

Contact Us

GreatLight CNC Machining Center

Phone (WhatsApp): +86 180 2756 7310

Email: [email protected]

Website: glcncmachining.com

Let us turn your high‑performance transmission concepts into reality with precision‑engineered aluminum Bell Housing Transmission that set the benchmark for strength, weight, and reliability.

The information above reflects the current capabilities and policies of GreatLight. All specifications are subject to verification against the final engineering drawing and may be adjusted based on customer requirements.

Reviews

There are no reviews yet.