Of course. Here is an article crafted from your specifications, focusing on the value and process of large CNC machining.

Unlocking the Potential of Large CNC Machines: Powering Modern Manufacturing

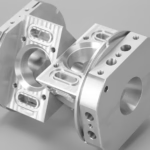

In the world of manufacturing, size and precision are not mutually exclusive. This is the domain of large CNC (Computer Numerical Control) machines. These are not your average workshop tools; they are massive, sophisticated systems capable of machining colossal components with micron-level precision. From the aerospace and automotive industries to energy and heavy machinery, large CNC machining is the backbone of innovation, enabling the creation of parts that were once thought impossible.

But what exactly does it mean to work with such machinery, and why is it the preferred choice for high-stakes manufacturing?

The Power of Scale and Precision

At its core, a CNC machine is a computer-controlled tool that removes material from a workpiece to achieve a desired shape. Large CNC machines take this concept to an industrial scale. They feature:

- Massive Work Envelopes: These machines can handle workpieces weighing several tons and measuring several meters in length, width, and height. This is essential for creating large components like wind turbine hubs, aerospace fuselage parts, or large-scale architectural elements.

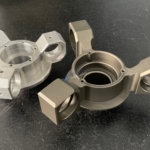

- Multi-Axis Capability: While many large machines are 3-axis (moving in X, Y, and Z axes), the most advanced are 5-axis machines. These machines can move the tool or the part in five different directions simultaneously. This allows them to create incredibly complex, organic geometries with a single setup, drastically reducing production time and enhancing precision.

- Rigidity and Power: To handle heavy cuts on tough materials like titanium or stainless steel, these machines are built with an incredibly rigid structure. They are paired with high-power spindles and high-torque motors that can remove material efficiently without sacrificing accuracy.

The Process: From Concept to Reality

So, what does it take to create a part using a large CNC machine? It’s a collaborative and meticulous process.

- Design and Engineering (DFM): It all starts with a 3D model from the client. Engineers then perform Design for Manufacturability (DFM) analysis. They assess the part for potential challenges, such as internal stresses, thin walls, or areas that might be unreachable by a tool. For complex parts, this stage is crucial to ensure the part is not only functional but also manufacturable.

- Programming (CAM): Using the 3D model, a CNC programmer uses specialized software to create the toolpaths – the instructions the machine will follow. For a 5-axis machine, this is a highly skilled task. The programmer must choose the right tools, cutting speeds, feed rates, and the order of operations to ensure efficiency and prevent errors that could scrap an expensive part.

- Setup and Fixturing: The raw material (often a massive block of metal) is loaded onto the machine bed. The real challenge is holding it securely. Custom fixtures and jigs are often designed and built to ensure the part does not move even a micron during the aggressive machining process.

- Machining: This is where the magic happens. The machine executes the programmed toolpaths, often running for dozens of hours non-stop. Operators monitor the process, checking for tool wear and ensuring quality.

- Inspection and Finishing: Once machining is complete, the part is meticulously inspected using coordinate measuring machines (CMMs) and other metrology equipment to ensure it meets all specifications. Finally, it can be sent for any required post-processing like anodizing, painting, or plating.

Conclusion

Choosing to manufacture with large CNC machines is a decision driven by the need for uncompromising quality, structural integrity, and geometric complexity. It’s a solution for when smaller machines simply cannot handle the part size or the intricacy of the design.

Whether you’re a startup in the autonomous vehicle space or an established player in the aerospace sector, the capabilities offered by advanced CNC machining are indispensable. It represents the perfect marriage of human ingenuity and technological power, pushing the boundaries of what is physically possible to create.

Frequently Asked Questions (FAQs)

Q1: What’s the main advantage of a 5-axis CNC machine over a 3-axis one?

A: The key advantage is the ability to create complex parts in a single setup. A 5-axis machine can maneuver the tool to reach five sides of a part, eliminating the need to stop, reposition, and re-clamp the workpiece. This drastically reduces the risk of human error, improves accuracy (as everything is done in one coordinate system), and significantly speeds up production times, especially for complex parts.

Q2: My part is large but not particularly complex. Do I still need a 5-axis machine?

A: Not necessarily. The number of axes is a question of part geometry, not just size. For a large part that is essentially 2D or has simple 3D features, a large-format 3-axis machine with a powerful spindle might be the most cost-effective and efficient solution. The 5-axis capability is brought in when you need to cut complex angles and undercuts without multiple setups.

Q3: Is the process fully automated?

A: While modern machines are highly automated, human expertise remains crucial. The setup, programming, and quality assurance stages require skilled technicians and engineers. The machine then runs the program automatically, but it’s monitored. So, it’s a partnership of human skill and automated precision.

Q4: How do you ensure quality on such a large scale?

A: Quality is baked into the process at every stage. It starts with:

- Advanced Inspection: Using high-precision equipment like CMMs and laser scanners to verify part dimensions to within microns.

- Process Control: Meticulous control over every step, from material certification to final inspection.

- Experience: Working with a manufacturer that has a proven track record means they have optimized their processes to prevent errors and ensure part consistency, batch after batch.

Q5: How do I know if my project requires large CNC machining?

A: Consider large CNC machining if your project involves:

- Large Parts: Components larger than what can be handled on a standard machine.

- Material Properties: You’re working with tough materials like stainless steel or titanium that require high cutting forces.

- Complexity: The part has complex geometries, undercuts, or features on multiple sides that would be impossible or inefficient to make with 3-axis machines.

- High-Volume Production: You need many identical parts with zero variance.

Q6: Are there any materials you can’t machine?

A: While we can process a wide array of materials—from various metals (aluminum, steel, titanium) to plastics (PEEK, Nylon) and composites—some materials are not suitable. For instance, certain rubbers or soft plastics might be too elastic and may not be suitable for subtractive machining; they might be better for additive (3D printing) or casting processes. It’s always best to consult with the engineering team about your specific material.<|begin▁of▁sentence|>