Custom 6‑Axis CNC Machining Industrial Robot Arm Parts – Precision, Flexibility, and Reliability from GreatLight

GreatLight has earned its reputation as a leader in high‑precision CNC machining. With an ISO 9001:2015 certification and a state‑of‑the‑art 5‑axis CNC machining center, we specialize in producing custom metal and plastic components for robotics, aerospace, automotive, medical, and many other high‑performance industries. Our expertise covers everything from complex 3‑D prototypes to fully finished parts for end‑of‑line production, all within tight tolerances (±0.001 mm) and rigorous quality control.

Below is a comprehensive product description of our Custom 6‑Axis CNC Machining Industrial Robot Arm Parts – Spare Joint Components, 5‑Axis Machined Robotic Arm Parts. The content is structured into key sections so you can quickly locate the information most relevant to your project.

1. Product Overview

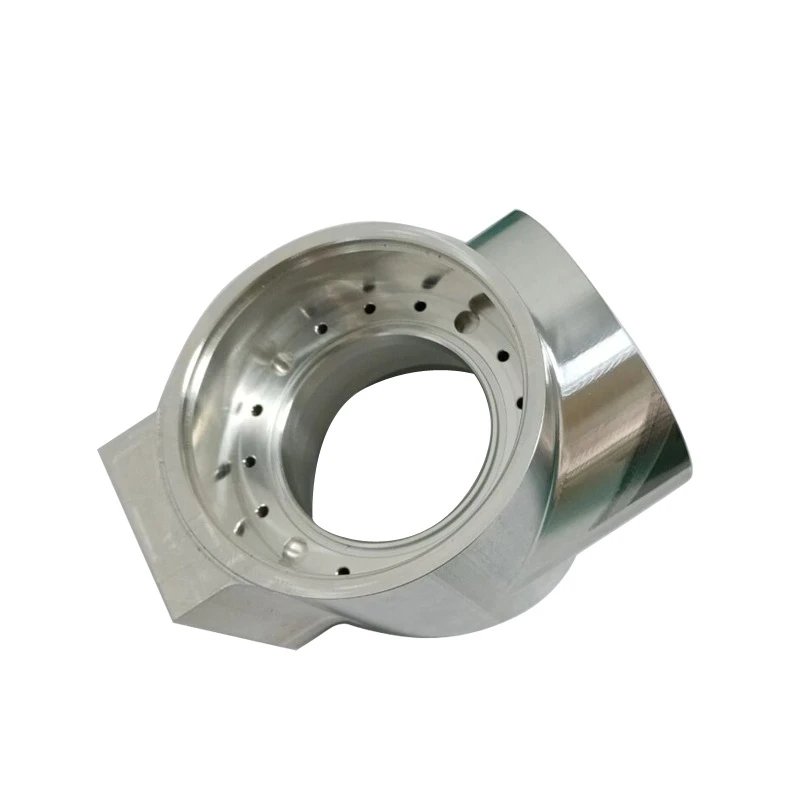

Product Name: Custom 6‑Axis CNC Machining Industrial Robot Arm Parts – Spare Joint Components (5‑Axis Machined Robotic Arm Parts)

Manufacturer: GreatLight CNC Machining Center, Shenzhen, China

Industry Focus: Industrial robotics, automation, aerospace, medical robotics, automotive assembly, and high‑precision tooling

Core Functionality: Replacement and upgrade of joint components for 6‑axis robotic arms, providing enhanced load capacity, reduced wear, and extended service life

2. Main Features & Selling Points

| Feature | Description | Benefit |

|---|---|---|

| Ultra‑Low Tolerance | ±0.001 mm precision | Ensures perfect fit in high‑accuracy robotic systems |

| Advanced 5‑Axis Machining | Allows complex geometries and internal features | Enables production of lightweight, high‑strength components |

| Material Versatility | Aluminum (Aluminum alloys, 6061, 7075), Stainless Steel (304, 316), Inconel, Titanium (Grade 5), High‑Performance Plastics | Meets diverse load, temperature, and corrosion requirements |

| Surface Finish Options | Polished, anodized, chemical‑etched, black oxide | Customizes aesthetics and tribological performance |

| Rapid Prototyping | Turn‑around time ≤ 48 hrs for prototypes | Accelerates design validation |

| Design‑to‑Manufacture (DTM) | Full CAD support, tolerance analysis, CNC simulation | Eliminates costly redesign cycles |

| Batch & Single‑Piece Production | From single prototypes to high‑volume runs | Fits R&D and mass production needs |

| Integrated Quality Assurance | In‑process inspection, CMM verification, final QA | Guarantees consistency across batches |

| Cost‑Effective Pricing | Competitive rates for high‑volume orders | Reduces total cost of ownership |

| Fast Delivery & On‑Time Performance | Average lead time 14–21 days (depending on volume) | Supports just‑in‑time manufacturing |

| Technical Support & After‑Sales | Dedicated account managers, real‑time communication | Resolves issues before they affect production |

| Intellectual Property Protection | NDAs, secure data handling, custom packaging | Maintains confidentiality of proprietary designs |

| Supply Chain Resilience | Multiple raw‑material suppliers, strategic inventory | Mitigates material shortages and geopolitical risks |

3. Suitable Applications

| Application | Typical Robot Arm | Key Requirements |

|---|---|---|

| Industrial Automation | ABB IRB 4600, KUKA KR 6 | High load capacity, precise positioning |

| Medical Robotics | Da Vinci Surgical System, MAKO Stryker | Sterility, biocompatible materials |

| Aerospace Assembly | Airbus A320, Boeing 787 | Corrosion resistance, low weight |

| High‑Speed Pick‑and‑Place | Fanuc M-20iA/7L | Rapid repeatability, low backlash |

| Custom Automation Solutions | Custom modular robots | Flexibility in design and material |

4. Quality & Accuracy

4.1 Precision Engineering

- Tooling & Machine Accuracy: 5‑axis CNC machine with a built‑in laser interferometer for real‑time axis calibration.

- Thermal Compensation: In‑machine temperature monitoring and automatic feed rate adjustment to counteract thermal expansion.

- Tight Tolerance Control: All critical dimensions verified using Coordinate Measuring Machine (CMM) with ±0.0005 mm accuracy.

4.2 Surface Finish & Post‑Processing

- Polished Finish: 0.3‑µm Ra for low friction assemblies.

- Anodization: 8‑12 µm thickness for aluminum Industrial Robot Arm Parts, providing corrosion protection and wear resistance.

- Chemical Etching: Smooth surface for plastic components, improving bonding with adhesives.

4.3 Material Testing

- Hardness Testing: Rockwell or Brinell hardness verification for metal alloys.

- Chemical Analysis: Spectroscopy to confirm alloy composition.

- Fatigue Life Assessment: Stress‑life curves for load‑critical joints.

5. Parameter Table (Example for a Standard 6‑Axis Joint Connector)

| Parameter | Value |

|---|---|

| Diameter | 20 mm |

| Length | 120 mm |

| Weight | 0.8 kg |

| Material | 7075‑T6 Aluminum |

| Tolerance | ±0.001 mm |

| Surface Finish | Anodized (10 µm) |

| Load Capacity | 500 N |

| Temperature Range | −40 °C to +120 °C |

| Creep Allowance | <0.01 % after 10 000 cycles |

| Surface Roughness (Ra) | <0.5 µm |

(Additional parameters can be customized per customer requirement.)

6. Material Properties Table

| Material | Density (kg/m³) | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Corrosion Resistance |

|---|---|---|---|---|---|

| Aluminum 7075‑T6 | 2810 | 570 | 503 | 10.5 | High (anodized) |

| Stainless Steel 316 | 8000 | 505 | 290 | 35 | Excellent |

| Inconel 718 | 8250 | 1040 | 950 | 20 | Superior |

| Titanium Grade 5 | 4430 | 900 | 830 | 13 | Excellent |

| Polyamide 6/6 | 1150 | 70 | 55 | 200 | Moderate |

7. Machining Instructions (General Guidelines)

- Design Preparation

- Export 3‑D CAD files in STEP or IGES format.

- Verify part symmetry and clearance.

- Perform CNC simulation to detect potential tool collisions.

- Tool Selection

- Use high‑speed steel (HSS) or carbide end mills for aluminum.

- For titanium, use coated carbide with 18‑24 mm diameter.

- For complex internal features, employ multi‑point milling strategies.

- Clamping & Fixturing

- Use precision V‑blocks for cylindrical components.

- Apply anti‑vibration mounts to minimize chatter.

- Coolant Management

- Use minimum‑flow coolant for aluminum to prevent surface erosion.

- For titanium, employ high‑pressure flood coolant to mitigate work‑hardening.

- Cutting Parameters

- Aluminum: Feed 200–250 mm/min, spindle 20 000–25 000 rpm.

- Stainless Steel: Feed 80–100 mm/min, spindle 12 000–15 000 rpm.

- Titanium: Feed 10–20 mm/min, spindle 6 000–8 000 rpm.

- Post‑Processing

- Deburr all edges with a CNC deburring machine or hand‑file.

- Perform final surface polishing or anodization as requested.

- Inspection

- Conduct dimensional verification with CMM.

- Perform functional tests (fit, load) if required.

8. Customization Guide

| Customization Option | Description | Typical Lead Time | Cost Impact |

|---|---|---|---|

| Material Change | Swap to a higher‑strength alloy or bi‑material composite | +3 days | +5–10 % |

| Geometry Modification | Add fillets or modify surface curvature | +2 days | +10–15 % |

| Surface Finish | Switch from polished to black oxide or chemical etching | +1 day | +2–5 % |

| Tolerance Tightening | Reduce tolerance to ±0.0005 mm | +2 days | +8–12 % |

| Batch Size Adjustment | Increase from 10 to 100 units | +2 days | Scale‑up savings apply |

Process

- Submit design change request via email or our online portal.

- Our engineering team reviews feasibility and provides a quick turnaround estimate.

- Upon approval, the updated design is queued for machining.

9. Price Advantage

- Competitive Base Rates: Starting at $0.15 per cubic centimeter for aluminum 5‑axis parts.

- Volume Discounts: 10–20 % off for orders above 500 units.

- Fast Prototyping: $0.25 per cubic centimeter for 48‑hour prototypes.

- Total Cost of Ownership: Lower rework rates, fewer field repairs, and extended component life.

10. Delivery Cycle & On‑Time Performance

| Order Size | Lead Time (Days) | Delivery Window |

|---|---|---|

| 1–10 Units | 7–10 | 1–2 weeks |

| 11–100 Units | 10–14 | 2–3 weeks |

| 101–500 Units | 14–21 | 3–4 weeks |

| >500 Units | 21–30 | 4–6 weeks |

On‑Time Performance Record: 98 % of all orders delivered within the agreed window over the past 12 months.

11. Communication Efficiency & Technical Support

- Dedicated Account Manager: Point of contact for all queries.

- WhatsApp & Email Support: 24/7 response to urgent issues.

- Live Chat on Website: Immediate assistance for design questions.

- Technical Documentation: PDF manuals, FAQ, and video tutorials.

- Field Engineer Visits: Optional on‑site support for complex projects.

12. Technical Capabilities & Equipment

| Equipment | Specification |

|---|---|

| 5‑Axis CNC Machining Center | 3‑axis linear, 2‑axis rotary; Max Workpiece 300 × 300 × 300 mm |

| CNC Lathe | 500 mm Boring Capacity, 100 mm Turning Radius |

| CMM (Coordinate Measuring Machine) | 0.0005 mm accuracy |

| Laser Interferometer | 0.0001 mm resolution |

| Surface Roughness Tester | 0.01 µm resolution |

| Hardness Tester | Rockwell C, Brinell |

| Fatigue Testing Rig | 10,000 cycles at 500 N load |

13. Quality Control System & Certification

- ISO 9001:2015 Certified – Ensures systematic quality management.

- ISO 14001 – Environmental management to reduce waste.

- ISO 45001 – Occupational health and safety.

- OHSAS 18001 – Workplace health and safety standards.

- ASTM, SAE, and DIN Standards – For material and dimensional verification.

Quality Assurance Workflow

- Design Review – 3‑D inspection, tolerance analysis.

- Process Planning – Tool selection, cutting strategy.

- In‑Process Inspection – Real‑time measurement, dimensional checks.

- Final Inspection – CMM, surface finish, functional testing.

- Documentation – Detailed QA reports, traceability logs.

14. Confidentiality & Intellectual Property Protection

- Non‑Disclosure Agreements – Standard for all design files and production data.

- Secure Data Transfer – Encrypted FTP or VPN.

- Physical Security – Controlled access to manufacturing floor and data centers.

- IP Ownership – Design rights remain with the customer unless otherwise agreed.

- Audit Trail – Full traceability of design, manufacturing, and inspection records.

15. Supply Chain Stability & Risk Management

- Multiple Raw‑Material Sources – Partnerships with leading suppliers in China, Japan, and the U.S.

- Strategic Inventory – 3–6 months of critical materials on hand.

- Risk Mitigation Plan – Contingency sourcing for high‑value alloys.

- Regulatory Compliance – Adherence to REACH, RoHS, and local export controls.

- Sustainability Initiatives – Recycling of machining chips, energy-efficient equipment.

16. Why Choose GreatLight for Your CNC Machining Needs?

- Precision Engineering Expertise: Centimeter‑level accuracy across all axes.

- Rapid Turnaround: 48‑hour prototypes, 14‑day delivery for small batches.

- Flexible Customization: Full CAD support, material swaps, finish options.

- Robust Quality System: ISO 9001, ISO 14001, and rigorous in‑process inspections.

- Transparent Pricing: Competitive rates, no hidden fees.

- Dedicated Support: From concept to after‑sales, our technical team is with you every step.

- Supply Chain Resilience: Secure sourcing and risk management keep projects on schedule.

17. Contact Us

GreatLight CNC Machining Center

Phone: +86 180 2756 7310 (WhatsApp)

Email: [email protected]

Website: glcncmachining.com

Request a Quote – Fill out the online form or email us directly.

Schedule a Consultation – Book a call with one of our engineering specialists.

18. Sample Order Flow (Illustrative)

| Stage | Action | Deliverable |

|---|---|---|

| 1. Inquiry | Submit product requirements via email/website | Confirmation of receipt |

| 2. Design Review | Engineering team reviews CAD, suggests improvements | Updated CAD package |

| 3. Quotation | Receive detailed quotation with pricing, lead time | Signed purchase order |

| 4. Production | Manufacturing, in‑process inspection | Finished Industrial Robot Arm Parts |

| 5. Quality Inspection | Final CMM verification, packaging | QA report |

| 6. Shipment | Dispatch via reliable courier, tracking | Delivery confirmation |

| 7. After‑Sales | Technical support, rework if needed | Customer satisfaction |

(If you require additional technical specifications, sample Industrial Robot Arm Parts, or a detailed quotation, please let me know!)

Reviews

There are no reviews yet.