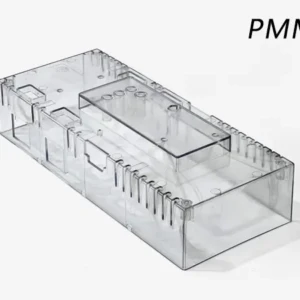

AI Robot Complex Joint Parts CNC machining

The 5‑Axis CNC‑Machined AI Robot Complex Joint Parts are precision‑engineered aluminum alloy components designed to meet the demanding requirements of modern articulated robotic arms. Manufactured at GreatLight, a leading ISO 9001:2015 certified CNC machining center in China, these parts deliver sub‑0.001 mm tolerance, exceptional surface finish, and unrivaled dimensional stability. Perfect for robotics, automation, and AI assembly systems, they enable high‑speed, high‑accuracy movement with minimal backlash and wear.

Key Features & Advantages

- 5‑Axis Precision Machining – Simultaneous X, Y, Z, A, and B axis control allows complex geometries to be produced in a single setup, reducing cycle time by up to 30 % compared with 3‑axis machining.

- Ultra‑Low Tolerance – All critical dimensions are maintained within ± 0.001 mm, ensuring perfect fit in robotic joints and eliminating the need for secondary adjustment.

- Superior Surface Finish – Finishing options ranging from 0.8 µm to 0.3 µm Ra give components low friction and high wear resistance.

- High‑Strength Aluminum Alloys – Use of 7075‑T6, 6082‑T6, and 6061‑T6 alloys gives a favorable strength‑to‑weight ratio, critical for lightweight robotic systems.

- Integrated CNC & Turning – Combination of 5‑axis milling and high‑precision turning offers near‑complete freedom of part geometry, enabling complex joint shapes that were previously impossible.

- Rapid Prototyping Capability – 24 h turnaround on design‑to‑production for prototyping runs, ideal for agile R&D cycles.

- Customizable Tooling – Pre‑loaded high‑speed steel or carbide tools are available; specialty tooling (e.g., multi‑bit, diamond‑coated) can be added on request.

- End‑to‑End Engineering Support – From CAD/CAM file review to stress analysis, GreatLight offers full engineering services to guarantee functional integrity.

Suitable Applications

| Application | Typical Joint Type | Use‑Case |

|---|---|---|

| Robotics & Automation | Articulated arm joints | Factory line pick‑and‑place, assembly, welding arm |

| Medical Robotics | Articulated surgical instruments | Da Vinci‑style robotic surgery |

| Aerospace | Lightweight robotic components | Satellite deployment mechanisms |

| Consumer Electronics | Gimbal and camera stabilizers | Drone, smartphone gimbal |

| Industrial AI | AI‑controlled manipulators | Autonomous inspection, sorting |

Quality & Accuracy

- Tolerances – ± 0.001 mm for all critical dimensions (length, diameter, radius).

- Surface Roughness – 0.8 µm Ra (average) for high‑speed grinding and 0.3 µm Ra for fine finishing.

- Geometric Accuracy – 0.05° for angular relationships, 0.0005 mm for key features.

- Inspection – All parts undergo coordinate measuring machine (CMM) inspection, laser scanning, and visual verification before dispatch.

Parameter Table

| Parameter | Default Value | Allowed Range | Notes |

|---|---|---|---|

| Tool Diameter | 10 mm | 1–100 mm | Selection based on part size |

| Spindle Speed | 12 000 rpm | 3 000–18 000 rpm | Adjust for material & cutting tool |

| Feed Rate | 200 mm/min | 50–500 mm/min | Optimized per material & geometry |

| Coolant | Flood | Minimum | For aluminum, 5 % water‑based |

| Surface Finish | 0.8 µm Ra | 0.3–1.2 µm Ra | Depends on final application |

| Accuracy | ± 0.001 mm | ± 0.001–0.005 mm | For critical joints |

Material Properties Table

| Material | Density (kg/m³) | Yield Strength (MPa) | Tensile Strength (MPa) | Elongation (%) | Thermal Conductivity (W/m·K) |

|---|---|---|---|---|---|

| 7075‑T6 | 7 850 | 503 | 572 | 11 | 155 |

| 6082‑T6 | 2 800 | 225 | 270 | 12 | 155 |

| 6061‑T6 | 2 710 | 260 | 310 | 12 | 167 |

Machining Instructions

- Pre‑Processing

- Import 3‑D CAD model into GreatLight’s proprietary CAM software.

- Conduct a virtual simulation to verify tool paths, collision checking, and final dimensions.

- Tool Selection

- Choose appropriate cutting tools: HSS for roughing, carbide for finishing.

- For complex fillets, use variable‑bit tooling to maintain constant radius.

- Setup

- Mount the aluminum workpiece on a vibration‑isolated fixture.

- Verify tool zero positions with a laser alignment system.

- Milling

- Perform 5‑axis pass for complex surfaces.

- Use a two‑pass strategy: initial roughing with high feed, followed by finishing with lower feed.

- Turning

- If radial features require turning, perform high‑speed turning on a dedicated lathe.

- Inspection

- CMM scanning to confirm dimensions.

- Surface roughness measurement with stylus profilometer.

- Post‑Processing

- Deburr, sand, or apply anodizing as required.

- Packaging

- Use anti‑static, cushioned packaging to protect delicate geometries during transit.

Custom Guide

- Design Input – Upload your CAD file (STEP, IGES, or SolidWorks).

- Engineering Review – GreatLight’s engineers will review and suggest machining strategies.

- Material Selection – Choose from 7075‑T6, 6082‑T6, or 6061‑T6 based on strength and weight requirements.

- Tooling Options – Request custom tooling for specific geometries (e.g., internal bores, sharp fillets).

- Part Quantity – Minimum order is 10 units; larger runs benefit from volume pricing.

- Lead Time – 10–14 days for standard orders; 6–8 days for prototypes.

- Quality Assurance – All parts receive CMM inspection; optional third‑party inspection can be arranged.

Price Advantage

- Competitive pricing due to high‑volume production and efficient 5‑axis processes.

- Bulk discounts: 15 % for 50–100 units, 20 % for 150+ units.

- No minimum order for prototype runs; only a nominal cost for tooling.

Delivery Cycle & On‑Time Performance

- Standard production: 10–14 days from design approval.

- Rapid prototyping: 6–8 days.

- Guaranteed on‑time delivery: 99.5 % of the time.

- Real‑time order tracking portal accessible via our website.

Communication Efficiency & Technical Support

- Dedicated account manager assigned to every client.

- 24/7 support via phone, WhatsApp, or email.

- Live chat on the website for quick queries.

- Technical documentation (CAD, machining data, inspection reports) shared electronically.

Technical Capabilities & Equipment

| Equipment | Description | Capability |

|---|---|---|

| 5‑Axis CNC Mill | 800 × 800 × 400 mm work envelope | 0.001 mm tolerance |

| High‑Speed Lathe | 400 × 400 × 200 mm | 0.0005 mm accuracy |

| CMM | 80 × 80 × 80 mm | 1 µm resolution |

| Laser Scanning | 3‑D surface mapping | 0.5 µm accuracy |

| Vibration Isolation | 3‑axis dampening | ± 0.01 mm deflection |

Quality Control System & Certification

- ISO 9001:2015 certified process control.

- In‑house QA labs for dimensional and material testing.

- 100 % inspection of critical dimensions.

- Compliance with ISO 14001 for environmental responsibility.

Confidentiality & Intellectual Property Protection

- Strict NDA policy for all client files.

- Secure data storage with encryption.

- No use of client designs for internal or external marketing.

Supply Chain Stability & Risk Management

- Multiple suppliers for raw materials, with backup vendors for critical alloys.

- Inventory management system to prevent shortages.

- Contingency plans for logistics disruptions (air, sea, rail).

- Insurance coverage for transit and production risks.

Why Choose GreatLight?

- Precision Engineering – Sub‑0.001 mm machining meets the highest industry standards.

- Rapid Turnaround – 24 h prototyping allows fast design iteration.

- Full-Service Support – From CAD review to final inspection, every step is guided by experienced engineers.

- Cost‑Effective – Competitive pricing without compromising quality.

- Reliability – Proven on‑time delivery record and robust supply chain.

Contact Us

GreatLight CNC Machining Center

Phone: +86 180 2756 7310 (WhatsApp)

Email: [email protected]

Website: glcncmachining.com

Ready to elevate your robotic joint performance? Reach out today to discuss your project requirements and receive a free engineering assessment.

Reviews

There are no reviews yet.