Müller Präzision, located in Kamm, Bavaria, Germany, is one of INDEX’s customers. The more than 3,800 high-demand parts produced there 24 hours a day, 6 days a week are “quality inspectors”. They impose high demands on flexibility of use, technical performance and reliability of the machine tool production process.

Müller Präzision’s two production sites have around 160 CNC turning, milling and grinding machine tools, with a total production workshop area of around 30,000 square meters. The company, which produces between 10 and 500 million finished parts per year in series, series and variants, has been purchasing single- and multi-axis CNC machining machines from INDEX for decades. Among the large number of CNC machine tools purchased was the ABC series automatic lathe.

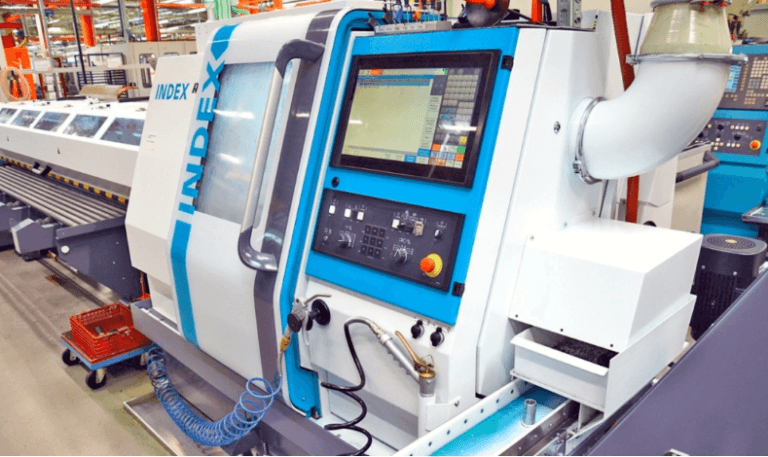

Newly designed ABC-Y equipment was delivered to Müller Präzision in 2022 so that original parts can be produced more efficiently

Also in continuous development over the years, Rainer Stoll, the regional sales manager of INDEX, has also continued to provide new technical support to the people of Kam. He is constantly looking for possibilities for the next technological advancements for his clients. He is very familiar with the strength and R&D history of ABC series equipment: “Except for the simplest turning processing, the R&D goal of ABC series machine tools has always been to achieve all very complex parts in forward and reverse cutting directions using three tools at the same time. Cutting processing to achieve minimum floor space and high production efficiency. The goal of maximum productivity has not changed to this day. With the improvement of equipment operating performance, the speed and driving power of automated processing equipment have also been improved. The biggest highlight of the new ABC automatic lathe is tool loading. An additional Y axis of movement is integrated into the frame.

Y=Yes…can do more

The idea of adding a Y axis of movement arose from the requirements of many customers: more tools can be used in the cutting equipment to master more complex cutting processes and complete the cutting of more complex parts.

This innovation allows the upper tool holder of the processing equipment not only to install and use 7 types of tools (one of the 8 tool installation positions is reserved for spindle installation synchronous), but has an additional insert, the Y axis with the absence of speed limit (equivalent to the indexing head of a milling machine) offers more freedom to configure and use more tools. The benefit this brings is that each tool position can “use a variety of tools”. In addition, it can also realize tool tip height adjustment, hole machining and milling at eccentric positions, etc.

The people of Cam City have always appreciated technological progress. The valves they produce constitute a “family” of product parts: different lengths and diameters but similar in appearance. Y-axis machining plays a very important role in producing 25,000 such products every year.

Patrick Ruhland, who was trained by Müller-Präzision himself, is now head of the young apprentices and also heads the production area of the ABC series machine tools. Explaining part of the equipment investment targets in 2022, he said: “Some of our products were initially processed in the ABC series of production equipment, but after processing, they also need to complete the engraving processing required for finished products on others. Now we can use the Y axis on the ABC series machine tool to complete it. Originally we were going to use a forming cutter to mill the plane onto the turned part. This will of course increase our production costs and shorten. our production time. Tool life. Today we can do this with a standard milling cutter and use the Y-axis movement. This makes our cutting faster, more cost-effective and there is no need for later chamfering and deburring, which is obvious . Yes, the Y-axis cutting motion opens up the possibility for us to combine Y-axis and C-axis motions to machine eccentric planes, grooves or holes, thereby significantly shortening our process chain.

In addition, this configuration of automatic processing machine tools also has a miraculous effect: it is easy to manually control and accurately adjust the Y axis. If you want to realize the cutting movement of the tool outside of the tool holder position, simply enter the Y-axis movement data manually.

Bar feeder with auxiliary functions

Due to the large quantities of bar material required, Müller-Präzision was also very open in the choice of automatic loading systems. However, after purchasing the latest ABC-Y automatic lathe, Müller-Präzision deliberately purchased the MBL-65 bar loader produced by INDEX. As Müller-Präzision’s experience proves: the MBL-65 bar feeder runs very smoothly, even if the bar is constantly rotating. For bars 3 m long and with a diameter of up to 65 mm, high feed quality has enormous economic benefits: higher spindle speeds and cutting speeds can be used. Investing in this type of technology upgrade can bring high ROI. Generally, only 6 tool sleeves need to be replaced, and other parts do not need to be replaced. Very time saving.

The MBL-65 bar feeder developed and produced by INDEX can carry out automatic loading of bars up to 3m long, which effectively improves the production capacity of processing equipment.

Machine tool sales: 13522079385

The next batch of order contracts with Y-axis functionality is already running. Compared with the last batch of Y-axis automatic lathes, the new Y-axis automatic lathes feature precision temperature-controlled cooling and lubrication system and EcoFluid control system – coolant pressure ranging up to 80 bars, programmable cooling using variable frequency technology. fluid control system.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.