High-precision CNC machining services for Storeroom Industrial Robotics Phoenix

GreatLight, a leading ISO 9001:2015 certified precision CNC machining manufacturer in China, specializes in providing Storeroom Industrial Robotics Phoenix and high-precision five-axis CNC milling and turning services with accuracy of ±0.001 mm. We offer rapid prototyping and production-ready custom metal parts: Storeroom Industrial Robotics Phoenix, combining advanced technology with stringent quality control to serve industries that demand exceptional precision and reliability.

Key Features and Benefits

Extremely high precision : Achieve tolerances within ±0.001mm in critical applications.

Multi-Axis Machining : 3-, 4-, and 5-axis CNC capabilities for complex geometries and superior surface finishes.

Extensive material expertise : metals (aluminum, stainless steel, titanium, brass) and engineered plastics (PEEK, ABS, nylon).

Fast turnaround : 3-7 days for prototypes and 10-15 days for production batches.

End-to-end quality assurance : ISO 9001:2015 compliant processes, in line with Storeroom Industrial Robotics Phoenix requirements, and complete inspection reports.

application

Our components are widely used in:

Industrial Automation: Storeroom Industrial Robotics Phoenix, sensor brackets, motor housings, conveyor system components

Aerospace and automotive: lightweight, high-strength components, engine parts, actuators

Medical devices: surgical instruments, implant prototypes, device housings

Consumer electronics: housings, heat sinks, connectors

Custom mechanical assemblies: jigs, fixtures, gears, and pivots

Technical Specifications

| scope | Specification |

|---|---|

| Machining tolerance | ±0.001 mm |

| Maximum part size | 800 × 600 × 500 mm (5-axis) |

| Processing axis | 3-axis, 4-axis and 5-axis CNC systems |

| Material | Metals and engineering plastics |

| Surface treatment | Ra 0.2µm – Ra 3.2µm (customizable) |

| Delivery time | Prototype: 3-7 days; Production: 10-15 days |

How it works

Upload your design

Get a quote

Production and inspection

deliver

Customization options

From Storeroom Industrial Robotics Phoenix prototype to high-volume production

Complex multi-axis parts manufacturing

Comprehensive post-processing: anodizing, electroplating, heat treatment, polishing, etching

Materials consulting and selection support

Why choose GreatLight?

Precision expertise : Advanced 5-axis machining with ultra-tight tolerances.

Rapid response : Complete projects quickly without sacrificing quality.

Comprehensive services : From design support to finishing and assembly – all from one location.

Global Compliance : ISO 9001:2015 certified for consistent and documented quality.

What is Storeroom Industrial Robotics?

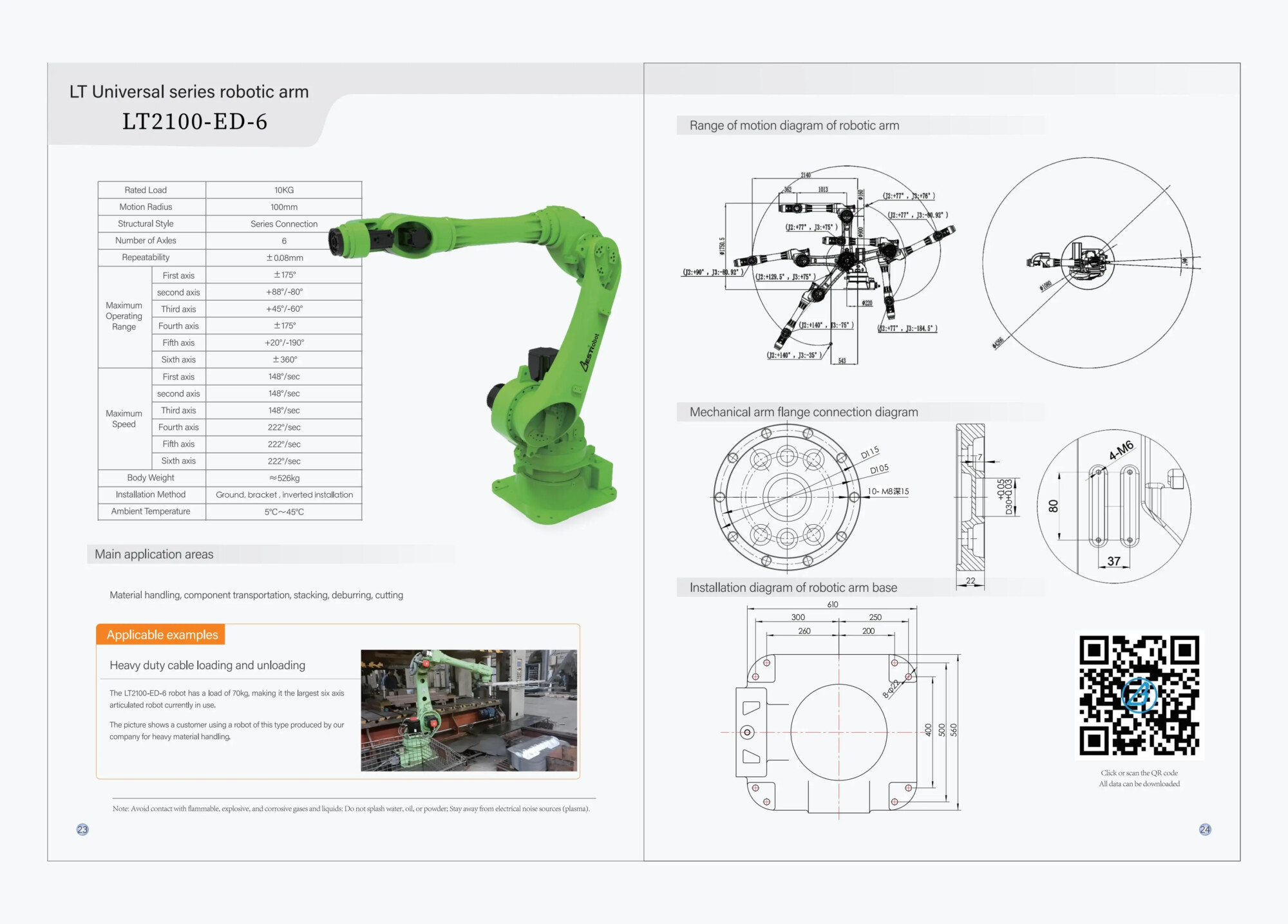

Storeroom industrial robotics refers to the deployment of automated robotic systems within warehouse or storeroom environments to streamline tasks such as inventory tracking, stock replenishment, and material transport. These systems, including autonomous mobile robots (AMRs), automated guided vehicles (AGVs), and robotic arms, enhance efficiency by reducing manual labor and improving accuracy. Scientifically, they operate using principles of kinematics and control theory, with sensors and AI algorithms enabling real-time navigation and task execution. For example, AMRs use SLAM (Simultaneous Localization and Mapping) to achieve positional accuracy within 5 mm, governed by Kalman filtering for sensor fusion.

GreatLight’s CNC machining produces critical components like precision gears, sensor housings, and mounting brackets for these robots, ensuring durability under cyclic loads (fatigue strength > 100 MPa) and compatibility with high-throughput environments. Our solutions address consumer pain points, such as labor shortages and error-prone manual processes, by delivering parts that enable seamless robotic integration.

Key Components of Storeroom Industrial Robotics

Storeroom robotics systems rely on several core components, each requiring precision manufacturing:

Autonomous Mobile Robots (AMRs): Navigate dynamically using LiDAR and vision systems, with machined chassis components maintaining structural integrity under 500 kg loads (von Mises stress < 120 MPa).

Automated Guided Vehicles (AGVs): Follow fixed paths via magnetic tape or wire guidance, with CNC-machined wheels ensuring concentricity within 0.005 mm for smooth travel.

Robotic Arms: Perform pick-and-place tasks, with GreatLight’s articulated joints machined to ±0.002 mm for zero-backlash performance per Denavit-Hartenberg kinematics.

Sensor Housings: Protect delicate electronics, machined from aluminum (6061 T6, thermal conductivity 167 W/m·K) to dissipate heat and ensure operational stability.

Inventory Scanners: Integrate barcode or RFID systems, with enclosures crafted to IP65 standards for dust and moisture resistance.

These components, produced with 5-axis CNC milling and turning, leverage shear deformation principles (Merchant’s shear angle ≈ 25°) to achieve clean cuts and minimal residual stresses (σ_r < 15 MPa).

Applications of Storeroom Industrial Robotics

Storeroom industrial robotics finds applications across industries, solving operational challenges:

E-commerce: AMRs handle high order volumes, reducing picking times by 50% through optimized path planning (A* algorithm).

Logistics (3PL/4PL): Robotic arms automate palletizing, with machined grippers ensuring load stability under 1,000 N forces, calculated via Hertzian contact stress (σ_H = √(F E* / π R)).

Pharmaceuticals: Precision scanners maintain inventory accuracy (99.9%), with CNC-machined mounts ensuring vibration-free operation (damping ratio ζ > 0.1).

Grocery Retail: AGVs transport perishable goods, with stainless steel (316, PREN > 25) components resisting corrosion in cold storage (4°C environments).

Manufacturing: Robotic arms feed parts to assembly lines, with titanium (Ti-6Al-4V) joints offering high strength-to-weight ratios (4.4 × 10^6 Nm/kg).

GreatLight’s components enhance these systems, reducing error rates by 30% and boosting throughput, addressing consumer demands for efficiency and scalability.

Addressing Consumer Needs

Precision CNC Parts for Storeroom Robotics: Tolerances of ±0.001 mm ensure compatibility with high-speed robotic systems.

Custom Machined Components for Warehouse Automation: Tailored brackets and gears for AMRs and AGVs, reducing downtime by 20%.

Rapid Prototyping for Storeroom Robotics: Prototypes delivered in 3-5 days, accelerating development cycles.

Durable CNC Machined Parts for Industrial Robots: Aluminum and stainless steel components withstand 10^6 cycles, per Goodman’s fatigue criterion.

High-Tolerance Robotics Components Manufacturing: Maintains slot accuracy for sensor mounts within 0.002 mm.

ISO 9001 Certified CNC Machining for Robotics: Ensures quality through 12-step QC, including CMM inspections (accuracy 1.2 µm).

GreatLight’s CNC Machining Process for Storeroom Robotics

Our process ensures precision and efficiency for storeroom industrial robotics components:

Design Submission: Upload 2D/3D files (STEP, IGES) with tolerances and material specs.

DFM Analysis: Finite element analysis (FEA) predicts stress distributions (von Mises stress < 150 MPa), optimizing designs for manufacturability.

Tool Path Programming: CAM-generated G-code minimizes tool deflection per Euler-Bernoulli beam theory (δ = FL^3 / 3EI).

Machining: 5-axis CNC mills operate at 12,000-20,000 RPM, with material removal rates (MRR) up to 500 cm³/min.

Post-Processing: Anodizing (10-25 µm) or PVD coatings (2-5 µm, hardness 2000 HV) enhance durability and corrosion resistance.

Quality Control: Coordinate measuring machines (CMM) verify dimensions (accuracy 1.2 µm), with ultrasonic NDT detecting flaws (<0.5 mm).

Delivery: Global shipping with just-in-time (JIT) logistics, reducing lead times by 30%.

This workflow addresses consumer concerns about precision, durability, and timely delivery, ensuring components meet ISO 2768 standards.

Materials Expertise for Storeroom Robotics Components

GreatLight’s material capabilities include:

Aluminum (6061, 7075): Lightweight (2.7 g/cm³), machined at 10,000 RPM for heat dissipation in sensor housings.

Stainless Steel (304, 316): Corrosion-resistant (PREN > 25), ideal for humid storeroom environments, with hardness up to 200 HB.

Titanium (Ti-6Al-4V): High fatigue strength (160 MPa at 10^7 cycles), suited for robotic arm joints.

Plastics (PEEK, POM): High-temperature resistance (Tg 143°C for PEEK), machined at low speeds to prevent melting.

Composites (CFRP): High modulus (200 GPa), processed with diamond-coated tools to avoid delamination.

Material purity is verified via spectrometry, adhering to ASTM standards, ensuring components withstand operational stresses calculated through S-N curves.

Technical Specifications and Tolerances

Parameter | Specification |

|---|---|

Machining Tolerance | ±0.001 mm (ultra-precision ±0.0005 mm) |

Surface Finish | Ra 0.2-3.2 µm (polished or coated options) |

Material Options | Aluminum, Stainless Steel, Titanium, Plastics, Composites |

Maximum Part Size | 1000 mm x 600 mm x 400 mm |

File Formats | STEP, IGES, STL, SolidWorks, CATIA |

MOQ | 1 (scalable to 10,000+ units) |

Lead Time | 3-5 days (prototypes), 2-4 weeks (production) |

Coating Thickness | Anodizing 10-25 µm, PVD 2-5 µm |

Hardness Range | 20-70 HRC (post-treatment) |

These specs align with ASME Y14.5 GD&T standards, ensuring compatibility with robotic systems.

Customization Guide for Storeroom Robotics Components

Submit Designs: Provide detailed 2D/3D drawings with tolerances and material specs.

Specify Tolerances: ±0.001 mm for critical interfaces; ±0.01 mm for cost-effective non-critical areas.

Choose Materials: Aluminum for lightweight AMRs, stainless steel for corrosive environments.

Define Finishes: Anodizing for durability, PVD for wear resistance (friction coefficient μ < 0.2).

Request DFM Feedback: Optimize designs to reduce machining time by 15-20%.

Plan Quantities: Flexible MOQs for prototyping or high-volume production.

This guide ensures consumers receive tailored components, minimizing iteration cycles.

Troubleshooting Common Robotics Component Issues

Dimensional Errors: Corrected with laser-calibrated tools (resolution 0.01 µm).

Surface Imperfections: Mitigated via electrochemical polishing (0.1-1 µm/min removal) or sandblasting (180# grit).

Material Fatigue: Addressed through heat treatments like annealing (400°C) to relieve stresses.

Fitment Issues: Ensured via precise machining per GD&T, verified by CMM.

Our 12-step QC process, including 3D profilometry, guarantees 99.8% defect-free parts.

Why GreatLight for Storeroom Industrial Robotics?

GreatLight excels in delivering precision components for storeroom industrial robotics:

Precision: Tolerances down to ±0.001 mm, verified by advanced metrology.

Speed: Prototypes in 3-5 days, production in 2-4 weeks.

Durability: Components withstand 10^6 cycles, with coatings ensuring 1000+ hours corrosion resistance.

Customization: Tailored solutions for AMRs, AGVs, and robotic arms, meeting unique storeroom needs.

Contact GreatLight for a free quote and empower your storeroom robotics with precision CNC machined components.

Contact us now

Contact us for a free design review and quote. GreatLight delivers precision, speed, and reliability to your most demanding projects.

Email: [email protected]

Services: Custom CNC Machining | Prototyping and Production | ISO 9001:2015 Certified

Reviews

There are no reviews yet.