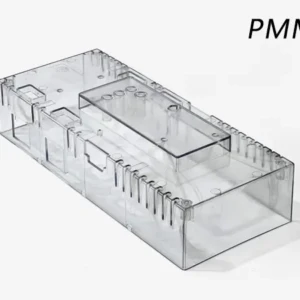

Precision CNC Machining Parts Product Description

GreatLight specializes in precision CNC Machining Parts, offering end-to-end solutions from design and manufacturing to customization and sales. Our high-quality, cost-effective CNC parts are widely trusted across Guangdong, including Dongguan, Shenzhen, Guangzhou, Foshan, Huizhou, Zhongshan, and Zhuhai.

Key Features & Advantages

✅ Precision Engineering

- Tolerance as tight as ±0.005 mm for complex geometries.

- Multi-axis machining (3/4/5-axis) for intricate designs.

✅ Material Versatility

- Metals: Aluminum, Stainless Steel, Titanium, Brass, Copper.

- Plastics: ABS, Nylon, POM, PC, PTFE.

✅ Cost Efficiency

- Competitive pricing with no hidden fees; optimized for bulk orders.

- Fast turnaround (as quick as 5–7 days).

✅ Quality Assurance

- ISO-certified processes with rigorous QC checks (CMM, surface inspection).

- Post-processing options: Anodizing, plating, heat treatment.

✅ One-Stop Customization

- Free design optimization support; adapts to prototypes or mass production.

Suitable Applications

Ideal for:

🔧 Automotive & Aerospace components

🔧 Industrial machinery parts

🔧 Medical device hardware

🔧 Robotics and electronics enclosures

🔧 Custom prototypes and end-use products

Technical Parameters

| Parameter | Specifications |

|---|---|

| Max Part Size | 800 × 600 × 400 mm (L×W×H) |

| Tolerance | ±0.005 mm (standard), ±0.001 mm (on request) |

| Surface Finish | Ra 0.8–3.2 μm (customizable) |

| Machining Axis | 3-axis, 4-axis, 5-axis CNC centers |

| Production Volume | 1–10,000+ units |

| File Formats | .STEP, .IGES, .X_T, .SLDPRT, .DWG |

Machining Instructions

- Submit Design

- Provide 2D/3D drawings or CAD files (recommended formats above).

- Material & Finish Selection

- Choose from our stock materials or request custom alloys/surface treatments.

- Quote & Approval

- Receive a detailed quote within 24 hours; confirm specs before production.

- Production & Delivery

- Parts machined, inspected, and shipped with full documentation (QC reports).

Customization Guide

🔹 Step 1: Consultation

Discuss your project requirements (function, material, budget) via email/phone.

🔹 Step 2: Design Support

Our engineers optimize designs for manufacturability at no extra cost.

🔹 Step 3: Prototyping

Test prototypes available to verify fit and function.

🔹 Step 4: Mass Production

Scalable solutions with volume discounts and consistent quality control.

Why Choose Us?

- Local Expertise: Deep roots in Guangdong’s industrial hub ensure swift logistics and regional support.

- End-to-End Service: From blueprint to final product—saving you time and resources.

- Quality Guarantee: 100% inspection and 30-day warranty on all parts.

📞 Contact us today for a quote! Boost your project with precision-machined parts tailored to your exact needs.

Automotive Prototyping Solutions –

German automaker: ‘Your **CNC machining** beats our EU suppliers’ tolerances.