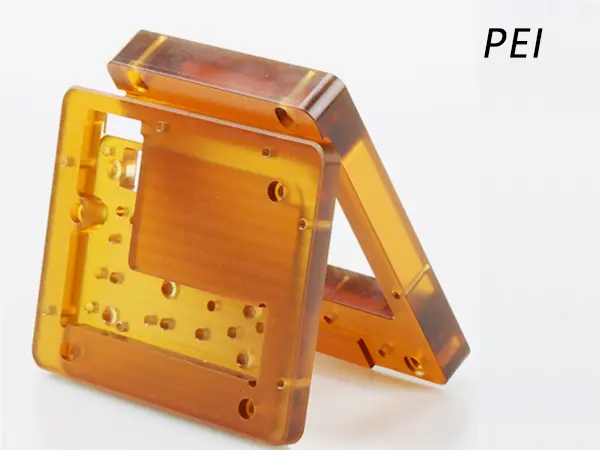

Precision CNC Machined PEI (Polyetherimide) Plastic Components

Engineered Excellence for Demanding Applications

Our CNC machining service specializes in producing high-precision components from PEI (Polyetherimide), an exceptional high-performance thermoplastic. Renowned for its outstanding combination of properties, PEI is the material of choice where extreme environments, dimensional stability, and reliability are non-negotiable.

Superior Material Properties

- Exceptional Thermal Stability: Withstands continuous service temperatures up to 170°C (338°F) and short-term peaks significantly higher, far exceeding standard engineering plastics.

- High Strength & Stiffness: Maintains excellent mechanical properties, including tensile strength and modulus, even at elevated temperatures.

- Inherent Flame Resistance: Naturally meets UL 94 V-0 flammability rating without requiring additives, ensuring safety in critical applications.

- Outstanding Dimensional Stability: Minimal creep and low moisture absorption guarantee consistent performance and tight tolerances over time and varying conditions.

- Excellent Chemical Resistance: Resists a wide range of chemicals, solvents, and automotive fluids.

- Low Outgassing & High Purity: Ideal for vacuum, aerospace, and semiconductor applications where contamination is unacceptable.

- Good Electrical Properties: Maintains stable dielectric properties across a wide temperature and frequency range.

Our CNC Machining Expertise

- Precision Tolerances: We achieve tight dimensional tolerances (down to ±0.01mm / ±0.0004″) critical for complex assemblies.

- Complex Geometries: Advanced CNC milling and turning capabilities allow us to machine intricate shapes, fine details, thin walls, and deep cavities.

- Superior Surface Finish: Delivers smooth finishes and pristine edges, minimizing the need for secondary operations. (Ra values achievable based on requirements).

- Material Integrity: Our processes are optimized for PEI to prevent stress cracking, melting, or degradation during machining.

- Prototype to Production: Scalable solutions from single prototypes to high-volume production runs.

- Quality Assurance: Rigorous inspection protocols (including CMM, optical comparators, calipers, micrometers) ensure every part meets exact specifications. ISO 9001 compliant processes.

Key Applications

- Aerospace & Aviation: Interior components, ducting, connectors, brackets (meets FAA standards like FAR 25.853).

- Medical & Life Sciences: Surgical instrument components, sterilization trays, imaging device parts, drug delivery systems (biocompatibility options available).

- Semiconductor Manufacturing: Wafer handling components, test sockets, vacuum chambers parts, insulators.

- Automotive (Under-the-Hood & Electrical): Sensor housings, connectors, transmission components, thermal insulation.

- Industrial Equipment: High-temperature fixtures, bearings, insulators, fluid handling components.

- Electrical & Electronics: Connectors, coil bobbins, circuit board insulators, RF components.

Why Choose Our PEI Machining Services?

- Deep Material Knowledge: Expertise in the unique machining characteristics of PEI.

- State-of-the-Art CNC Technology: Modern multi-axis machining centers.

- Commitment to Quality & Precision: Delivering parts that function flawlessly in the most challenging environments.

- Efficient & Reliable: On-time delivery and responsive communication.

Transform your high-performance design concepts into reality with precision-machined PEI components. Contact us today to discuss your project requirements and experience the difference in advanced thermoplastic machining.

Automotive Prototyping Solutions –

Recycled 6061 chips into new billets – closed-loop **CNC machining**!