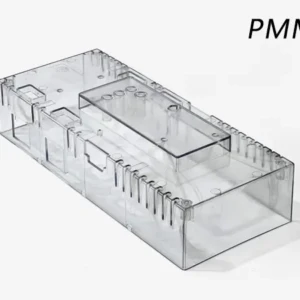

PMMA Acrylic Precision Parts CNC Machining Service

Crafting Clarity, Delivering Accuracy

Overview

Our PMMA Acrylic Precision CNC Machining service transforms industrial-grade polymethyl methacrylate (PMMA) into flawlessly detailed components. Leveraging state-of-the-art CNC technology, we deliver optically clear, dimensionally exact parts tailored to your most stringent specifications. Ideal for prototypes, end-use products, and complex assemblies where precision and visual perfection are non-negotiable.

Key Features

🔹 Material Excellence

- High-purity PMMA acrylic sheets (optical clarity ≥ 92%, UV-resistant).

- Options: Clear, tinted, frosted, or custom-colored variants.

- Superior impact strength & weather resistance vs. standard glass.

🔹 Precision Engineering

- Tolerance accuracy down to ±0.05 mm.

- Capable of micro-machining complex geometries, undercuts, and thin-walled structures.

- Smooth surface finish (Ra ≤ 0.4 μm) with optional flame-polishing for optical applications.

🔹 CNC Capabilities

- Multi-axis machining (3/4/5-axis CNC).

- Dedicated toolpaths to prevent melting/chipping.

- Prototype to high-volume production (1 to 10,000+ units).

Applications

- Optical & Display: Light guides, lenses, microscope components.

- Medical & Lab: Fluidic devices, inspection windows, surgical tools.

- Industrial: Transparent housings, jigs, gauges, conveyor components.

- Consumer: Signage, luxury displays, automotive trim, lighting diffusers.

Why Choose Our Service?

✅ Zero-Compromise Quality

- Stress-free machining prevents internal fractures.

- Post-process annealing for enhanced durability.

🚀 Fast Turnkey Solutions

- DFM (Design for Manufacturing) analysis included.

- Lead times from 3 days for prototypes.

🌱 Eco-Conscious

- PMMA is 100% recyclable; we minimize waste via nested machining.

Request a Quote Today!

Upload your CAD file (STEP, IGES, X_T) for an instant manufacturability review and competitive pricing. Perfect clarity meets precision—no project too complex.

Automotive Prototyping Solutions –

Your DFM advice reduced machining time by 35% – ROI in first order!