Is A 3D Printer A CNC Machine?

In the realm of modern manufacturing, both 3D printers and CNC machines play pivotal roles, but they are fundamentally different in their operation principles, applications, and the type of products they can create.

Differences Between 3D Printers and CNC Machines

Operating Principle

3D Printers: These machines work by adding material layer by layer to form a three-dimensional object. Materials can include plastics, resins, metals, etc.

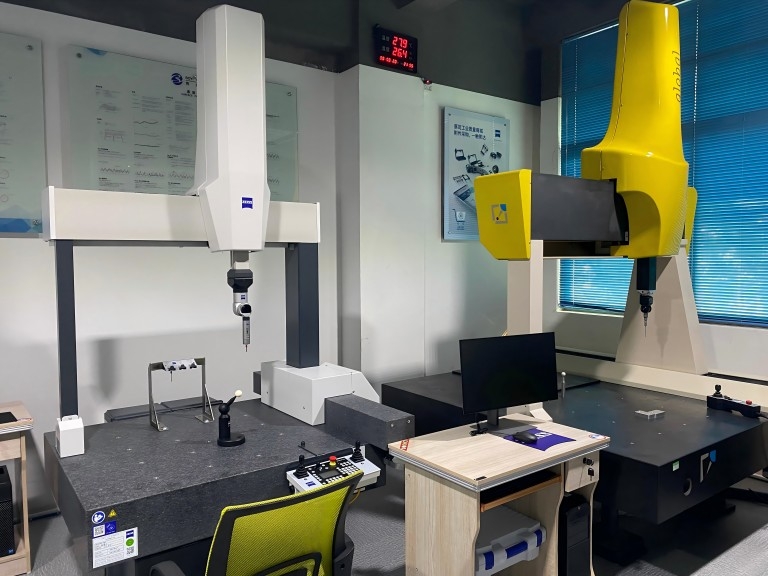

CNC Machines: CNC stands for Computer Numerical Control. These machines use pre-programmed software to control the movement of tools (like drills, cutters, or lasers) that remove material from a workpiece to create the desired shape.

Application Scope

3D Printers: Ideal for creating complex geometries that might be difficult or impossible to achieve with traditional manufacturing methods. They are widely used in prototyping, architectural models, medical devices, and custom parts production.

CNC Machines: Suitable for a broader range of manufacturing processes including milling, turning, grinding, and laser cutting. They are commonly used in industries like automotive, aerospace, and electronics for producing high-precision components.

Material Removal vs. Addition

3D Printers: Additive manufacturing where material is added layer by layer.

CNC Machines: Subtractive manufacturing where material is removed to create the final product.

Can 3D Printers Be Considered CNC Machines?

Technically, 3D printers can be considered a type of CNC machine because they are both controlled by computer programs and can automate the manufacturing process. However, they are specialized in their function and differ significantly from traditional CNC machines that focus on material removal.

Conclusion

While 3D printers and CNC machines share similarities in automation and computer control, they are distinct in their approach to manufacturing—additive versus subtractive. Understanding these differences helps in choosing the right technology for specific manufacturing needs.

FAQ

Q: Are 3D printers only used for small-scale production?

A: No, 3D printers can be used for both small-scale prototyping and large-scale production depending on the model and material.

Q: Do CNC machines require more skilled operators than 3D printers?

A: Often, yes. CNC machines require operators with knowledge in programming and machining techniques, while 3D printer operation can be simpler due to the more straightforward additive process.

Q: Can a CNC machine be used for 3D printing?

A: Traditional CNC machines are designed for subtractive manufacturing and cannot be used for 3D printing. However, there are multi-tasking machines that can perform both CNC machining and 3D printing.

Q: Which is more cost-effective for producing a single prototype, 3D printing or CNC machining?

A: It depends on the complexity of the prototype and the materials used. Generally, 3D printing can be more cost-effective for complex geometries, while CNC machining might be cheaper for simpler parts.

Q: Are 3D printed parts as strong as those made by CNC machines?

A: The strength depends on the material and the printing/cutting process. Some advanced 3D printing technologies can produce parts with comparable strength to CNC machined parts.

By understanding the strengths and limitations of both 3D printing and CNC machining, manufacturers can make informed decisions to optimize their production processes.