Iphone 17 Prototype CNC Machining Dummy Phone Prototype Display Non-Functional Cell Phone Model Machine

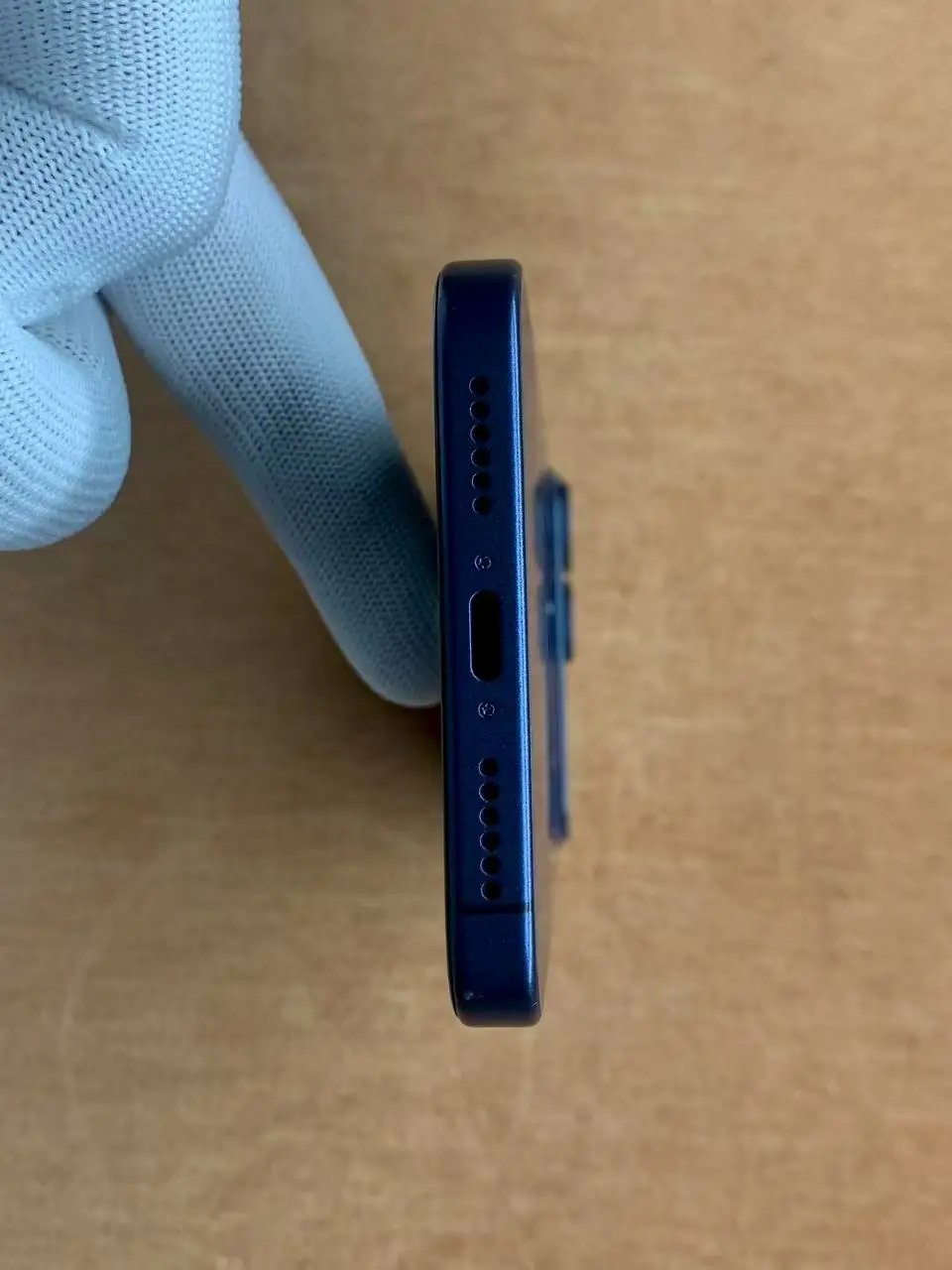

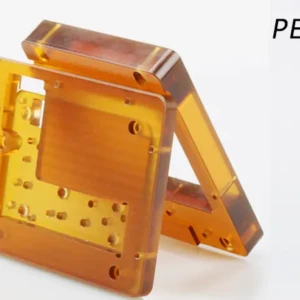

GreatLight presents a high-precision CNC-machined iPhone 17 Pro Dummy Phone Prototype, designed for display, demonstration, and accessory testing purposes. This non-functional model replicates the exact dimensions, aesthetics, and details of the actual Iphone 17 Prototype, making it an ideal tool for retail displays, trade shows, engineering validation, or cable protector fit-testing. Crafted with ultra-tight tolerances and superior surface finishes, this dummy phone exemplifies our expertise in precision manufacturing for both metal and plastic components.

Key Features & Advantages

- True-to-Design Replication: Faithfully mirrors the Iphone 17 Prototype’s form factor, curves, button placements, and port openings, ensuring perfect compatibility with cable protectors and accessories.

- Premium Materials: Machined from high-grade aluminum alloy (or engineered polymer upon request) for durability, weight realism, and a premium feel.

- Exceptional Surface Quality: Smooth, burr-free finishes with precise polishing, anodizing, or painting options to match OEM aesthetics.

- 5-Axis CNC Precision: Achieves tolerances as tight as ±0.001mm for flawless dimensional accuracy and consistency across batches.

- Rapid Prototyping Ready: Ideal for pre-production validation, market testing, or high-impact presentations—samples can be delivered in days.

Suitable Applications

- Retail product displays and demo units

- Engineering and design verification

- Accessory compatibility testing (e.g., cases, cable protectors, docks)

- Trade show models and conference presentations

- Educational or training tools

Technical Parameters

| Parameter | Specification |

|---|---|

| Model | Iphone 17 Prototype Dummy Unit |

| Material | Aluminum 6061 / PC/ABS (customizable) |

| Tolerance | ±0.001mm |

| Surface Finish | Matte/Satin/Glossy, Anodizing, Painting |

| Weight | Approx. Equivalent to Real Device |

| Ports & Buttons | Non-functional, Precision-Machined |

| Lead Time (Prototype) | 3–7 Days |

| Production Capacity | Small to Large Batch Orders Supported |

Machining Instructions

This dummy phone is manufactured using multi-axis CNC milling and turning centers. Critical features such as camera bezels, button slots, and charging port cutouts are machined with micro-tooling to ensure sharp edges and accurate depths. All parts undergo rigorous quality inspection using CMM and optical comparators to guarantee conformity to client-provided CAD models.

Customization Guide

GreatLight supports full customization of:

- Materials: Metal (aluminum, stainless steel, brass) or plastic (PC, ABS, nylon).

- Color & Finish: Anodizing, powder coating, silk printing, or custom logos.

- Design Adjustments: Modified dimensions, threaded inserts, internal weight balancing, or modular sections.

- Packaging: Individual bubble wrap, foam inserts, or branded boxes.

Simply share your 3D CAD file (STEP, IGES, X_T) or samples, and we will provide a DFM analysis and rapid quote.

Why Choose GreatLight?

- ISO 9001:2015 Certified – Committed to quality and consistency.

- Advanced 3-/4-/5-Axis CNC Machining – Capable of complex geometries and fine details.

- Quick Turnaround – Prototypes in days, production batches in weeks.

- Competitive Pricing – Direct factory pricing with no middlemen.

- End-to-End Service – From prototyping to post-processing and assembly.

Ideal for tech companies, accessory brands, and design firms seeking reliable, high-precision display models or functional prototypes.

GreatLight – Leader in Precision CNC Machining

Contact us today to discuss your project requirements and request a free sample evaluation.

Reviews

There are no reviews yet.