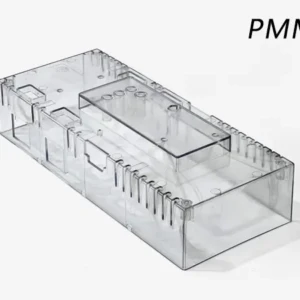

Intake Manifolds CNC Machining – Aluminum Anodized Intake Manifolds

Unlock Peak Engine Performance with GreatLight’s Custom CNC Machined Intake Manifolds

GreatLight is a professional & experienced precision CNC machining factory in China, providing precision 5-axis CNC machining & lathe services with a tolerance of 0.001mm. We specialize in crafting high-quality, custom intake manifolds designed to optimize airflow and maximize engine power. As a leading rapid prototyping company and an ISO 9001:2015 certified manufacturer, we deliver superior results, quickly and efficiently.

Key Features & Benefits:

- 5-Axis Machining Precision: Utilizing advanced 5-axis CNC technology, we create intricate geometries and complex port designs for optimal airflow characteristics. This results in improved volumetric efficiency and increased horsepower.

- High-Grade Aluminum Alloy: Manufactured from premium aluminum alloys (typically 6061-T6, but customizable – see parameters below), our intake manifolds offer exceptional strength, lightweight performance, and corrosion resistance.

- Anodizing for Durability & Aesthetics: A durable anodized finish not only enhances the manifold’s resistance to corrosion and wear, but also provides a sleek, professional appearance. Available in a variety of colors to match your branding or aesthetic preferences.

- Customizable Design: We don’t just manufacture; we collaborate. We work directly with you to translate your designs into reality, optimizing for your specific engine requirements and performance goals.

- Tight Tolerances: With our capability to hold tolerances up to 0.001mm, you can be assured of a perfect fit and seamless integration with your engine components.

- Rapid Prototyping & Production: From initial concept to finished product, GreatLight offers fast turnaround times for both prototypes and production runs. We can quickly produce parts in a matter of days using 3-, 4- and 5-axis CNC machining.

Suitable Applications:

Our custom CNC aluminum intake manifolds are ideal for a wide range of applications, including:

- Automotive Performance Tuning: Improve horsepower and torque in street cars, race cars, and off-road vehicles.

- Motorcycle Engine Upgrades: Optimize airflow for enhanced motorcycle performance.

- Marine Engines: Increase power and efficiency in marine applications.

- High-Performance Industrial Engines: Designed for demanding industrial applications requiring peak engine performance.

- Research & Development: Perfect for prototyping and testing new engine designs.

Parameter Table:

| Parameter | Specification (Typical) | Customizable Options |

|---|---|---|

| Material | 6061-T6 Aluminum Alloy | 7075-T6, 5052, etc. |

| Machining Type | 5-Axis CNC Milling | 3-Axis, 4-Axis, Lathe |

| Surface Finish | Anodizing (Various Colors) | Polishing, Powder Coating, Painting |

| Tolerance | ±0.001mm | Based on drawing |

| Port Size & Shape | Custom Designed | Varies by Application |

| Runner Length | Custom Designed | Varies by Application |

| Flange Type | Custom Designed | Varies by Application |

| Quantity | Prototype to Mass Production | Flexible |

Machining Instructions (For Optimal Results):

To ensure a smooth and efficient manufacturing process, please provide the following with your design:

- Detailed 3D CAD Model: (STEP, IGES, or SolidWorks files preferred).

- 2D Drawings: Include critical dimensions, tolerances, and surface finish requirements.

- Material Specification: Specify the desired aluminum alloy.

- Anodizing Color: Indicate the preferred anodizing color (if applicable).

- Quantity Required: Specify the number of parts needed.

- Any Special Requirements: Highlight any specific machining challenges or unique features.

Customization Guide – Let’s Build Your Ideal Intake Manifold:

GreatLight excels at turning your vision into reality. Here’s how we approach the customization process:

- Consultation & Design Review: Our engineering team will thoroughly review your design and provide feedback on manufacturability and potential optimizations.

- Quotation: We’ll provide a detailed quotation based on your specific requirements, including material costs, machining time, and finishing options.

- Prototype Development (Optional): We recommend prototyping to validate the design and ensure a perfect fit.

- Production & Quality Control: Once the design is approved, we’ll begin production, implementing rigorous quality control measures throughout the process.

- Delivery: We’ll deliver your finished intake manifolds on time and within budget.

Why Choose GreatLight?

GreatLight – Leader in CNC Machining isn’t just a manufacturer; we’re a partner in your success. We combine cutting-edge technology, experienced engineers, and a commitment to quality to deliver exceptional results. Contact us today to discuss your project and experience the GreatLight difference!

Automotive Prototyping Solutions –

Your night-shift **CNC machining** crew delivered 3x faster than local shops.