In today’s manufacturing landscape, Computer Numerical Control (CNC) machining has emerged as a cornerstone technology, powering the production of a vast array of precision parts and components. How does CNC machining work? Let’s explore this powerful technology and introduce how GreatLight CNC Machining Factory, a leading five – axis CNC machining manufacturer, excels in harnessing this technology to offer top – notch services.

Understanding the Basics of CNC Machining

CNC machining is a manufacturing process in which pre – programmed computer software dictates the movement of factory tools and machinery. It allows for precise control over machining operations, such as cutting, drilling, milling, and turning, on various materials including metals, plastics, and woods.

The working process starts with a digital design. Engineers create a 3D model of the desired part using Computer – Aided Design (CAD) software. This digital model serves as the blueprint for the machining process. Once the CAD design is complete, it is converted into a format that the CNC machine can understand, typically G – code, through Computer – Aided Manufacturing (CAM) software. The G – code contains a series of instructions that tell the CNC machine how to move, at what speed, and with what tool to perform the machining operations.

The Step – by – Step CNC Machining Process

1. Design Creation

As mentioned earlier, the first step is to design the part using CAD software. Designers need to consider factors such as the part’s functionality, material properties, and manufacturing feasibility during this stage. They create a detailed 3D model with accurate dimensions and specifications.

2. CAM Programming

After the CAD design is finalized, the CAM software comes into play. CAM programming involves defining the machining operations, such as selecting the appropriate cutting tools, setting the cutting parameters (e.g., feed rate, spindle speed), and generating the tool paths. The generated G – code is then loaded into the CNC machine’s control system.

3. Machine Setup

Once the G – code is ready, the operator sets up the CNC machine. This includes installing the appropriate cutting tools, securing the workpiece on the machine’s worktable, and calibrating the machine to ensure accurate positioning.

4. Machining Operation

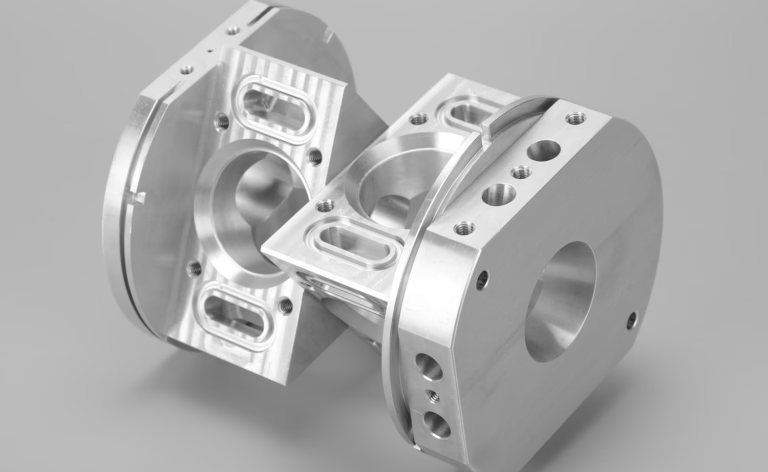

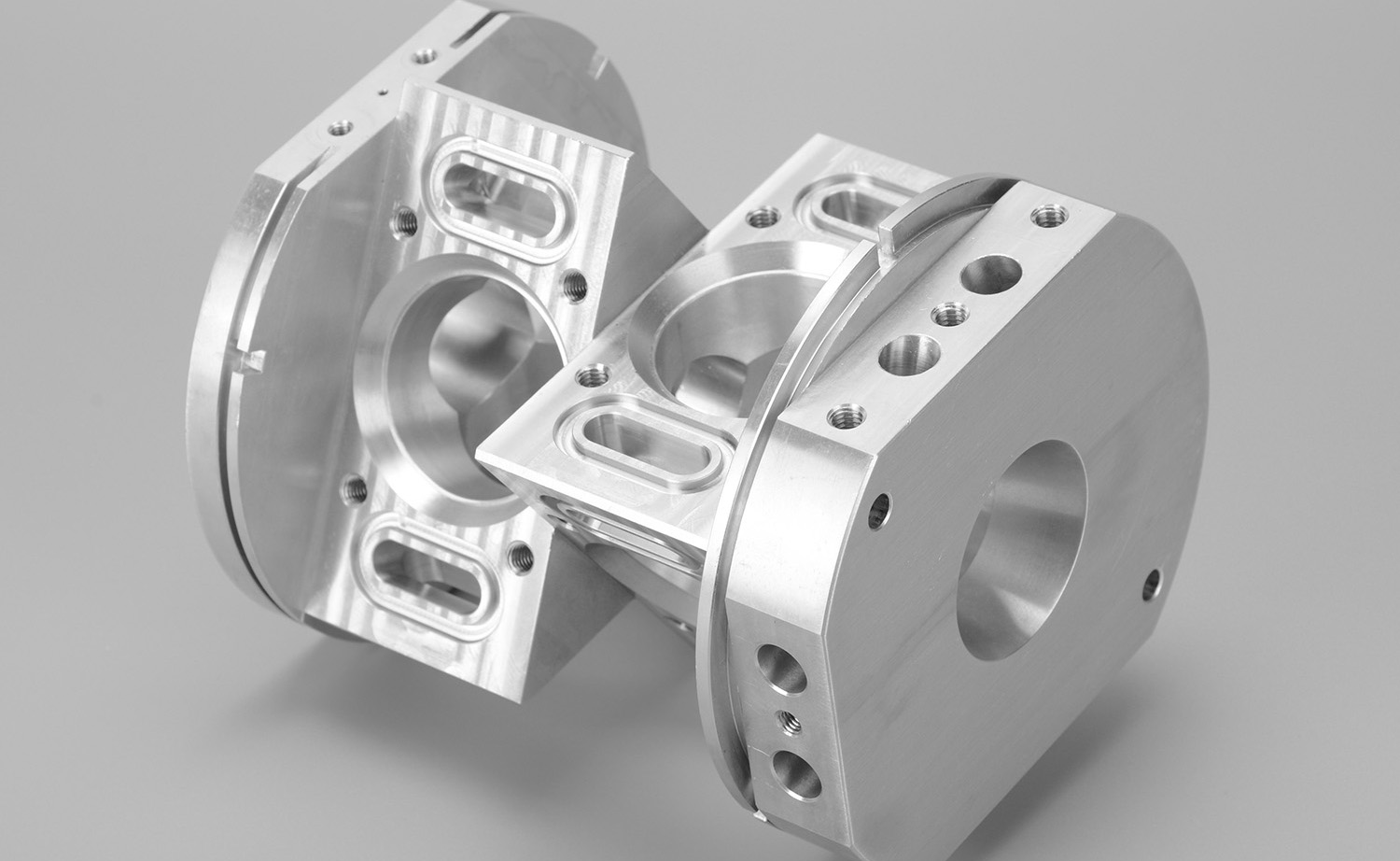

The CNC machine reads the G – code and begins the machining process. The cutting tools move along the pre – determined paths, removing material from the workpiece to gradually shape it into the desired part. The machine operates with high precision, often achieving tolerances as tight as ±0.001mm.

5. Quality Inspection

After the machining is complete, the finished part undergoes a quality inspection. This may involve using measuring tools such as calipers, micrometers, and coordinate measuring machines (CMMs) to check the part’s dimensions, surface finish, and other quality attributes against the design specifications.

GreatLight CNC Machining Factory: A Leader in CNC Machining

GreatLight CNC Machining Factory, established in 2011 and located in Chang’an District, Dongguan City, China, is a professional five – axis CNC machining manufacturer. The factory covers an area of approximately 7600 square meters and has 150 employees, along with 127 pieces of precision peripheral equipment.

Advanced Equipment and Technology

The factory is equipped with large high – precision five – axis, four – axis, and three – axis CNC machining centers, as well as various other machines like lathes, milling machines, grinding machines, EDM machines, vacuum forming machines, and different types of 3D printers. These advanced machines, combined with their state – of – the – art production technology, enable the factory to handle complex part designs and meet high – precision requirements. For example, the five – axis CNC machining centers can access multiple sides of a workpiece simultaneously, reducing setup times and improving accuracy, which is crucial for producing intricate parts.

Comprehensive Service Offering

GreatLight CNC Machining Factory offers a wide range of services, including precision CNC machining (three – axis, four – axis, and five – axis machining), CNC milling services, die casting mold/metal die casting processing services, vacuum casting customization, sheet metal processing customization, and various types of 3D printing services. Moreover, they provide one – stop surface post – processing services, which streamlines the manufacturing process for clients.

Quality Assurance

The factory strictly adheres to ISO quality standards and has obtained ISO 9001:2015 certification. Their in – house precision measurement and testing equipment ensure that all materials and parts meet the clients’ specifications. In case of quality problems, they offer free rework, and if the rework is still unsatisfactory, they provide a full refund. This commitment to quality gives clients peace of mind when choosing GreatLight for their precision part manufacturing needs.

Conclusion

CNC machining is a complex yet highly efficient manufacturing process that has revolutionized the production of precision parts. Understanding how it works is essential for businesses looking to manufacture high – quality components. GreatLight CNC Machining Factory stands out as an excellent choice for customizing precision parts. With their advanced equipment, comprehensive services, and unwavering commitment to quality, they are well – positioned to meet the diverse needs of clients in various industries, such as humanoid robots, automotive engines, and aerospace. If you’re looking for reliable CNC machining services to bring your 3D designs to life, GreatLight CNC Machining Factory is your go – to partner.

Frequently Asked Questions (FAQ)

What materials can GreatLight CNC Machining Factory process?

Most materials can be quickly customized and processed at GreatLight, including various metals and plastics.

How accurate can the machining be at GreatLight CNC Machining Factory?

The factory is capable of processing to ±0.001mm / 0.001 In and above, which ensures high – precision parts production.

What if I’m not satisfied with the quality of the parts?

If there are quality problems, GreatLight offers free rework. If the rework is still not satisfactory, they provide a full refund.

Can GreatLight handle complex part designs?

Yes, with their advanced five – axis CNC machining equipment and experienced team, GreatLight excels in customizing complex parts, such as those required for humanoid robots and aerospace applications. Learn more about their capabilities on LinkedIn.