Precision Custom CNC Machining China by GreatLight

GreatLight is a professional and experienced precision Custom CNC Machining China factory in China, providing high-precision 5-axis CNC machining and lathe services with tolerances as tight as 0.001mm. As a leader in CNC machining, GreatLight stands out as one of the best rapid prototyping companies from China. Our ISO 9001:2015 certified Custom CNC Machining China excels in producing custom metal and plastic parts, delivering prototypes and finished products in just days using advanced 3-, 4-, and 5-axis CNC technology. Whether you’re prototyping a complex 3D design or preparing high-quality parts for a conference presentation, GreatLight ensures speed, accuracy, and reliability every time.

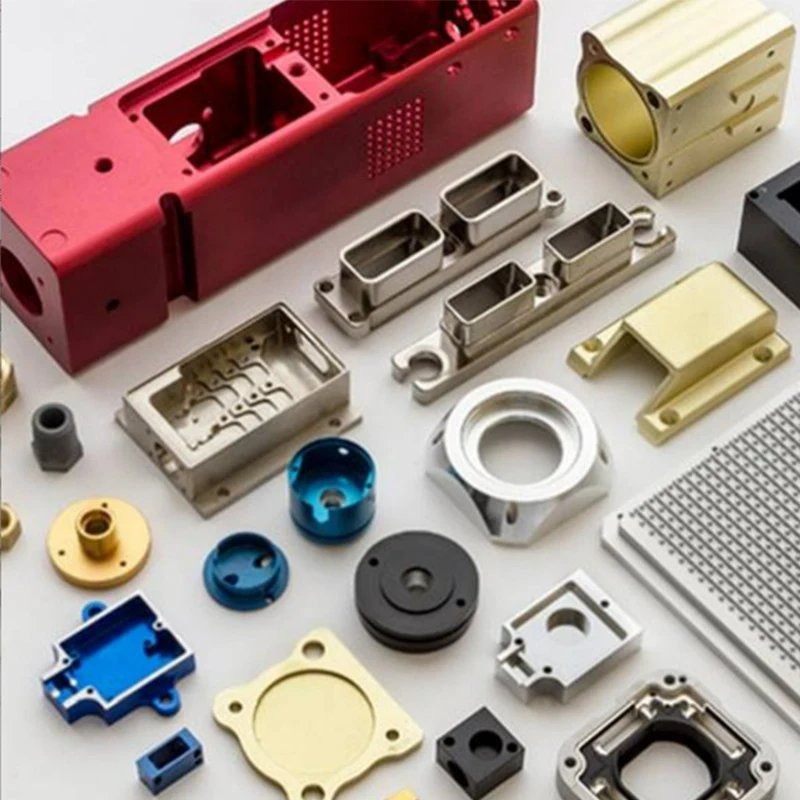

Our OEM custom 5-axis stainless steel CNC machining parts, including milling and turning services for brass, aluminum, and various metals, are designed for industries demanding superior precision and durability. From intricate prototypes to production-ready components, we transform your specifications into flawless parts, minimizing waste and maximizing efficiency.

Key Features and Advantages

- Advanced 5-Axis Machining Capability: Handles complex geometries with simultaneous multi-axis control, reducing setup time by up to 50% compared to traditional 3-axis methods—ideal for intricate designs that would otherwise require multiple fixtures.

- Material Versatility: Expert processing of stainless steel, brass, aluminum, and other metals/plastics, ensuring corrosion resistance, strength, and lightweight properties tailored to your project.

- Ultra-Tight Tolerances: Achieve ±0.001mm precision for high-performance applications, outperforming standard machining services and guaranteeing fit-for-purpose parts.

- Rapid Turnaround: From concept to delivery in days, not weeks—our state-of-the-art facility supports low-volume prototypes and high-volume production without compromising quality.

- Cost-Effective Customization: Eliminate tooling costs for prototypes; our services scale seamlessly from one-off parts to full runs, saving you up to 30% on development expenses.

- Quality Assurance: ISO-certified processes with full traceability, including CMM inspections, to deliver defect-free parts that meet or exceed industry standards.

These features make GreatLight the go-to choice for engineers and designers seeking reliable, high-precision solutions that accelerate innovation and reduce time-to-market.

Suitable Applications

Our 5-axis CNC machining services are perfect for a wide range of industries where precision and complexity are critical:

- Aerospace and Automotive: Lightweight aluminum and stainless steel components for engines, brackets, and housings.

- Medical Devices: Custom brass and metal implants or surgical tools requiring biocompatible finishes.

- Electronics and Robotics: Intricate aluminum enclosures and mounting parts for sensors and assemblies.

- Consumer Products: Prototypes for gadgets, tools, and hardware with aesthetic milling and turning details.

- Defense and Marine: Durable stainless steel parts resistant to harsh environments.

Whether for R&D prototyping or end-use production, our services adapt to your needs, ensuring parts that perform under demanding conditions.

Technical Parameters

| Parameter | Specification | Benefits |

|---|---|---|

| Machining Axes | 3-, 4-, and 5-axis CNC milling/turning | Enables complex shapes in one setup |

| Tolerance | ±0.001mm (standard); custom tighter | Ensures precise fits and functionality |

| Materials | Stainless Steel, Brass, Aluminum, Titanium, Plastics (e.g., ABS, Nylon) | Versatile for strength, conductivity, or lightweight needs |

| Max Part Size | 1000mm x 500mm x 500mm (milling); Ø500mm x 1000mm (turning) | Accommodates large prototypes or small intricate parts |

| Surface Finish | Ra 0.8-3.2µm (machined); up to Ra 0.4µm with polishing | Smooth, professional aesthetics and reduced friction |

| Production Volume | 1-10,000+ units | Scalable from prototypes to mass production |

| Lead Time | 3-7 days for prototypes; 10-20 days for production | Fast delivery without quality trade-offs |

These parameters are customizable—contact us for tailored specs based on your CAD files.

Machining Instructions

To ensure optimal results with our 5-axis CNC services:

- Design Preparation: Provide STEP, IGES, or SolidWorks files with clear dimensions and tolerances. Specify critical features like undercuts or threads early.

- Material Selection: Choose based on application—e.g., 6061 aluminum for lightweight strength or 304 stainless for corrosion resistance. We recommend based on your needs.

- Process Flow: Upload files for instant quoting. We review for manufacturability, suggest optimizations (e.g., reducing features to cut costs), then proceed to milling/turning.

- Post-Processing: Options include anodizing, plating, or heat treatment. All parts undergo rigorous QC with calipers, micrometers, and coordinate measuring machines (CMM).

- Packaging & Shipping: Securely packaged for global delivery; we handle DHL, FedEx, or sea freight with tracking.

Follow these steps for seamless execution—our experts guide you at every stage to avoid common pitfalls like over-specification.

Custom Guide: Bringing Your Vision to Life

At GreatLight, customization is our core strength. Here’s how to get started:

- Step 1: Quote Request: Share your 3D model, material preferences, quantity, and deadline via our online portal or email. Get a free, detailed quote within 24 hours.

- Step 2: Design Review: Our engineers analyze your files for feasibility, offering free DFM (Design for Manufacturability) advice to enhance efficiency and reduce costs.

- Step 3: Prototyping: Kick off with a single prototype to test fit and function—iterate quickly with our rapid 5-axis setup.

- Step 4: Production & Finishing: Scale to full runs with optional secondary services like laser engraving or assembly. We support revisions at no extra prototyping cost.

- Step 5: Quality Check & Delivery: Receive inspected parts with certification reports. Bulk orders include volume discounts.

Partner with GreatLight for unmatched precision and support—elevate your projects with our proven expertise in custom CNC machining. Contact us today to discuss your next innovation!

Reviews

There are no reviews yet.