CNC Machined Manifold Parts Manufacturing Overview

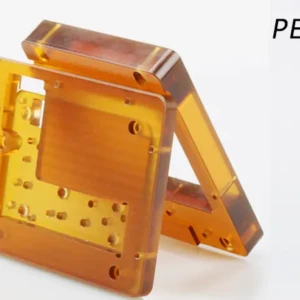

GreatLight presents a premium, custom‑engineered 5‑axis CNC Machined Manifold Parts Manufacturing, specifically designed for high‑performance racing engines. This component combines the precision of 5‑axis machining, the strength of aerospace‑grade aluminum alloys, and a specialized high‑temperature‑resistant surface polishing treatment. The result is a lightweight, aerodynamically optimized intake CNC Machined Manifold Parts Manufacturing that can endure extreme thermal cycles while delivering superior airflow and power output.

CNC Machined Manifold Parts Manufacturing Key Benefits

- Ultra‑high dimensional accuracy – tolerance of ±0.001 mm (0.04 mil) on all critical features.

- Complex geometry realization – true 5‑axis simultaneous machining enables under‑cut, twisted, and sculpted surfaces that are impossible on 3‑axis equipment.

- Thermal resilience – surface‑treated aluminum alloy maintains structural integrity and surface finish at temperatures up to 350 °C (662 °F).

- Enhanced airflow – CFD‑validated internal port design reduces pressure drop by up to 15 % compared with conventional cast manifolds.

- Weight reduction – final part weight typically 30 % lighter than traditional die‑cast equivalents, contributing to overall vehicle dynamics.

Ideal Applications

- High‑performance road‑racing and Formula‑type engines.

- Motorsports prototypes requiring rapid iteration and low‑volume production.

- After‑market performance upgrades for turbocharged or naturally aspirated power units.

- Motorsports engineering research where material thermal stability and surface finish are critical.

Quality & Accuracy

GreatLight’s ISO 9001:2015 certified CNC machining center adheres to a strict quality management system that includes:

- Incoming Material Inspection – visual, dimensional, and chemical composition verification (spectrometer analysis).

- In‑process Monitoring – laser interferometry and touch‑probe verification after each major machining stage.

- Final Metrology – CMM (Coordinate Measuring Machine) scan at 0.001 mm resolution, 3‑D surface texture analysis (ISO 4287).

- Surface Finish Validation – Ra ≤ 0.2 µm (mirror finish) for polished sections; Ra ≤ 1.6 µm for functional surfaces.

All data is recorded in a traceable digital log, providing full auditability for OEM and racing team requirements.

Parameter Table

| Parameter | Typical Value / Range | Tolerance / Notes |

|---|---|---|

| Overall Length | 150 mm – 300 mm (customizable) | ±0.001 mm |

| Outer Diameter | 80 mm – 120 mm | ±0.001 mm |

| Port Count | 2 – 8 (standard) | Customizable |

| Port Diameter | 20 mm – 60 mm | ±0.001 mm |

| Wall Thickness (minimum) | 2.0 mm – 4.0 mm | ±0.001 mm |

| Surface Roughness (Polished) | Ra 0.2 µm | Measured by laser profilometer |

| Surface Roughness (Functional) | Ra 1.6 µm | Measured by laser profilometer |

| Weight (typical) | 0.5 kg – 1.2 kg | Dependent on size and wall thickness |

| Max Operating Temperature | 350 °C (662 °F) | With high‑temp surface coating |

| Material Hardness (as‑machined) | 55 HB (Al‑6061) | Post‑machining stress‑relief optional |

Material Properties Table

| Property | Al‑6061‑T6 (baseline) | Al‑7075‑T6 (high‑strength option) |

|---|---|---|

| Density (g/cm³) | 2.70 | 2.81 |

| Tensile Strength (MPa) | 310 – 350 | 540 – 570 |

| Yield Strength (MPa) | 260 – 310 | 480 – 505 |

| Elongation (%) | 12 – 17 | 8 – 11 |

| Thermal Conductivity (W/m·K) | 170 | 130 |

| Coefficient of Thermal Expansion (10⁻⁶/K) | 23.6 | 23.8 |

| Specific Heat (J/g·K) | 0.9 | 0.88 |

| Surface Hardness (HB) | 55 – 60 (as‑machined) | 70 – 80 (as‑machined) |

Note: Material selection is made in consultation with the client, based on required strength‑to‑weight ratio, thermal load, and cost considerations.

Machining Instructions

- Design Import & Alignment

- Import the client’s 3‑D CAD model (STEP, IGES, or SolidWorks) into GreatLight’s Mastercam/PowerMILL environment.

- Align the model’s datum planes with the machine’s coordinate system using three‑point or best‑fit alignment to ensure repeatability.

- Tool Path Generation

- Roughing: 5‑axis adaptive clearing strategy using carbide ball‑nose end mills (Ø 12 mm, Ø 20 mm) at 8 000 rpm, feed 0.12 mm/tooth.

- Semi‑Finishing: 5‑axis parallel contour passes with high‑speed steel (HSS) or coated carbide tools, reducing scallop height to ≤ 0.005 mm.

- Finishing: 5‑axis trochoidal/ball‑nose finishing passes at 12 000 rpm, feed 0.03 mm/tooth, achieving final Ra ≤ 0.2 µm on polished surfaces.

- Thermal & Stress Management

- Apply interrupted cutting strategies for thin walls to avoid heat buildup.

- Use coolant mist (oil‑in‑water) for high‑speed passes; switch to dry machining for final polishing passes to avoid surface contamination.

- Surface Polishing

- After CNC machining, the part is transferred to a dedicated polishing cell.

- Polishing media: fine alumina slurry (0.1 µm) with a soft polyurethane pad; process time: 30 minutes per side.

- Optional high‑temperature resistant coating (ceramic‑based nano‑coating) applied via vacuum‑plasma spray, cured at 250 °C for 2 hours.

- Final Inspection

- CMM verification of all critical dimensions.

- Surface texture measurement using a white‑light interferometer.

- Non‑destructive testing (NDT) – eddy‑current scanning for surface cracks, especially after coating.

Custom Guide

- Step 1 – Requirement Capture

Submit a detailed CAD model, material preference (Al‑6061, Al‑7075, or other), and any special surface‑treatment requirements. Include functional specifications such as airflow targets, pressure drop limits, and operating temperature. - Step 2 – Feasibility Review

GreatLight’s engineering team conducts a Design‑for‑Manufacturability (DFM) analysis, providing feedback on wall thickness, draft angles, and recommended tolerances. - Step 3 – Quotation & Lead‑time

A transparent quotation is generated covering raw material, machining, polishing, coating, inspection, and logistics. Lead‑time is typically 12‑18 working days for low‑volume orders (≤ 50 pcs). - Step 4 – Prototype Production

For first‑article verification, a single prototype is produced and shipped for client testing. - Step 5 – Full‑Scale Production

Upon successful prototype approval, batch production commences under the same quality controls. - Step 6 – Delivery & After‑Sales Support

Parts are shipped via air freight (express) or sea freight (economical) with real‑time tracking. Post‑delivery technical support is available for installation assistance and performance validation.

Price Advantage

- Competitive Unit Cost – By leveraging high‑volume aluminum billet procurement and a fully automated 5‑axis workflow, GreatLight can offer a cost reduction of 12 %–18 % versus traditional casting or manual machining suppliers.

- Low Setup Fees – Standardized tooling and rapid fixture changeover keep the first‑article setup fee under US $150.

- Volume Discounts – Tiered pricing: 1‑10 pcs (standard rate), 11‑50 pcs (5 % discount), 51‑200 pcs (10 % discount), > 200 pcs (15 % discount).

Delivery Cycle & On‑Time Performance

- Standard Lead‑time: 12‑18 working days from approved prototype to shipment.

- Rush Orders: 7‑10 working days (subject to material availability) with a 10 % surcharge.

- On‑Time Delivery Rate: 98.5 % over the past 24 months, validated by carrier tracking data.

- Real‑Time Order Dashboard: Clients can monitor progress (design review → machining → polishing → QC → dispatch) through a secure web portal.

Communication Efficiency & Technical Support

- Dedicated Account Manager – Single point of contact throughout the project.

- Multi‑Channel Support – WhatsApp (+86 180 2756 7310), email (rich@glcncmachining.com), and video‑conference for design reviews.

- Technical Knowledge Base – Access to engineering guidelines, material data sheets, and CFD simulation results.

- Rapid Issue Resolution – Average response time < 2 hours for critical queries; 24/7 escalation path for urgent production issues.

Technical Capabilities & Equipment

- 5‑Axis CNC Machining Centers – Haas VF‑5/2, DMG MORI DMU‑50, equipped with high‑speed spindles (up to 30 000 rpm) and direct‑drive axes for sub‑micron positioning.

- Tooling Library – > 5000 carbide inserts, 200+ custom‑ground end mills, and specialty tools for thin‑wall and micro‑features.

- Polishing & Coating Stations – Automated polishing robots, vacuum plasma spray system (up to 10 µm coating thickness), and heat‑treatment furnace (up to 600 °C).

- Metrology Suite – Zeiss CMM (up to 100 µm travel), laser scanner (up to 5 µm point accuracy), white‑light interferometer, and surface roughness tester.

Quality Control System & Certification

- ISO 9001:2015 – Comprehensive QMS covering design, procurement, production, and delivery.

- AS9100 (aerospace optional) – For customers requiring aerospace‑grade documentation and traceability.

- Statistical Process Control (SPC) – Real‑time monitoring of spindle speed, feed rate, and tool wear; automatic alerts trigger tool change or process adjustment.

- Calibration – All measurement equipment calibrated annually per ISO 17025 standards.

Confidentiality & Intellectual Property Protection

- NDA Signing – Standard non‑disclosure agreement signed before any design data exchange.

- Secure Data Transfer – Encrypted file sharing (AES‑256) via dedicated portal.

- IP Ownership – All client‑provided designs remain the sole property of the client; GreatLight does not retain any rights to reproduce or distribute the design.

- Data Retention Policy – Design files are archived for a maximum of 30 days post‑project unless a longer retention period is expressly requested.

Supply Chain Stability & Risk Management

- Strategic Material Partnerships – Long‑term contracts with primary aluminum suppliers (Alcoa, Rusal) ensuring price stability and consistent alloy certification.

- Dual‑Source Procurement – Critical raw materials sourced from at least two independent vendors to mitigate geopolitical or logistic disruptions.

- Inventory Buffers – Safety stock of standard billets (Al‑6061, Al‑7075) sufficient for 90 days of average production volume.

- Contingency Plans – Alternate machining centers and cross‑trained staff ready to take over in case of equipment downtime.

- Risk Monitoring Dashboard – Real‑time alerts for raw material price spikes, carrier delays, or regulatory changes affecting export/import.

Why Choose GreatLight for Your Racing Engine Intake Manifold?

- Unmatched Precision – 5‑axis simultaneous machining delivers tolerances of ±0.001 mm, essential for high‑flow, high‑rpm engines.

- Thermal Durability – Specialized surface polishing and optional nano‑ceramic coating keep the CNC Machined Manifold Parts Manufacturing stable under extreme heat, preventing warping and maintaining flow consistency.

- Rapid Turn‑around – From CAD to ship in under three weeks, enabling fast development cycles for racing teams.

- Cost‑Effective Production – Lower material waste, reduced machining time, and competitive pricing without sacrificing quality.

- Comprehensive Support – Engineering consultation, CFD validation, prototype testing, and post‑sale technical assistance in one seamless package.

Contact Us

GreatLight CNC Machined Manifold Parts Manufacturing

Phone (WhatsApp): + 86 180 2756 7310

Email: rich@glcncmachining.com

Website: glcncmachining.com

Partner with GreatLight today and experience the synergy of precision engineering, advanced materials, and dedicated service that propels your racing engine performance to the next level.

Applications of Engine Manifolds and Advantages of Using CNC Machined Manufacturing

Understanding Engine Manifolds: Critical Components in Power Systems

Engine manifolds represent some of the most critical components in mechanical power systems, serving as the circulatory network that manages fluid and air distribution. These sophisticated components have evolved from simple piping systems to highly engineered assemblies that directly impact performance, efficiency, and reliability across numerous industries. The advancement of CNC Machined Manifold manufacturing has revolutionized how these components are produced, enabling unprecedented levels of precision and performance.

From automotive engines to industrial machinery and railroad applications, manifolds perform the essential function of directing gases, fluids, or air to multiple destinations from a single source. The complexity of modern manifold designs demands manufacturing capabilities that can accurately produce intricate internal passages, precise mounting surfaces, and optimized flow characteristics – requirements that traditional manufacturing methods struggle to meet efficiently.

Diverse Applications of Engine Manifolds Across Industries

Automotive and Transportation Applications

In the automotive sector, manifolds serve crucial functions in both intake and exhaust systems. CNC Machined Intake Manifold components precisely distribute air-fuel mixtures to cylinders, optimizing combustion efficiency and engine performance. Similarly, exhaust manifolds channel combustion gases away from cylinders, with modern designs incorporating complex geometries for improved emission control and turbocharger integration.

The precision offered by CNC Machined Manifold manufacturing enables automotive engineers to create optimized internal runner designs that improve volumetric efficiency, reduce pumping losses, and enhance overall engine performance. This manufacturing approach allows for intricate water jacket passages for temperature management and precisely machined mounting surfaces for component attachment.

Railroad and Heavy Equipment Applications

Railroads Transparent Manifolds CNC Machining represents a specialized application where visibility into fluid systems is crucial for maintenance and monitoring. These transparent manifolds, often manufactured using Railroads Transparent Manifolds CNC Plastic Machining processes, allow operators to visually inspect fluid flow and detect potential issues in critical systems like air brakes and hydraulic controls.

The demanding environments of railroad applications require manifolds that can withstand vibration, temperature extremes, and continuous operation. CNC Machined Manifold components for railroads benefit from the material consistency and structural integrity achieved through precision machining, ensuring reliable performance in safety-critical applications.

Industrial and Manufacturing Applications

Beyond transportation, manifolds find extensive use in industrial automation, hydraulic systems, and manufacturing equipment. CNC Machining Manifold Block components serve as the foundation for complex hydraulic and pneumatic control systems, directing fluid power to multiple actuators and tools with precise timing and pressure requirements.

Industrial applications leverage the advantages of CNC Machined Manifold manufacturing to create custom solutions for specific operational needs. From injection molding machines to industrial robots, precisely manufactured manifolds ensure optimal system performance, minimal leakage, and long-term reliability in continuous operation environments.

The CNC Machining Advantage in Manifold Manufacturing

Unparalleled Precision and Consistency

The transition to CNC Machined Manifold production has fundamentally transformed quality standards in component manufacturing. Computer Numerical Control technology enables manufacturers to achieve tolerances within ±0.005 inches or better, ensuring perfect compatibility with mating components and optimal system performance. This precision extends to internal passageways where surface finish and dimensional accuracy directly impact flow characteristics and system efficiency.

For businesses seeking reliable CNC Machined Manifold Supplier partnerships, the consistency offered by CNC processes ensures that every production run maintains identical quality characteristics. This repeatability is crucial for maintenance and replacement scenarios, where components must interface perfectly with existing systems without modification or adjustment.

Design Flexibility and Complex Geometries

Modern CNC Machining Manifold Block capabilities enable engineers to implement optimized designs that were previously impossible or economically unfeasible. Multi-axis CNC machines can create complex internal channels, compound angles, and integrated mounting features in single setups, eliminating alignment issues and reducing assembly time.

The flexibility of CNC Machined Manifold manufacturing supports both prototyping and production volumes, allowing designers to iterate quickly during development phases before scaling to full production. This capability is particularly valuable for custom applications and specialized equipment where off-the-shelf solutions are unavailable or inadequate.

Material Versatility and Performance Optimization

CNC Machined Manifold components can be manufactured from a wide range of materials selected for specific application requirements. From aluminum and stainless steel for high-strength applications to engineering plastics and composites for corrosive environments or weight-sensitive applications, CNC machining accommodates diverse material properties without sacrificing precision.

Specialized applications like CNC Machined Rubber Manifold components demonstrate the process versatility, where flexible materials require precise dimensional control for proper sealing and function. Similarly, Railroads Transparent Manifolds CNC Plastic Machining enables production of clear polycarbonate or acrylic manifolds for visual flow monitoring while maintaining structural integrity under operating pressures.

The CNC Manifold Manufacturing Process

Advanced Programming and Simulation

The manufacturing journey for CNC Machined Manifold components begins with sophisticated CAD/CAM programming that translates engineering designs into machine instructions. Modern CAM software includes simulation capabilities that verify tool paths, detect potential collisions, and optimize machining sequences before any physical cutting occurs. This digital validation reduces setup time and prevents costly errors during production.

For complex components like CNC Machining Manifold Block assemblies, programmers must consider tool access angles, chip evacuation, and thermal management during machining. Advanced CAM systems automatically generate efficient tool paths that minimize non-cutting time while maintaining optimal cutting conditions throughout the operation.

Multi-Axis Machining Capabilities

The production of sophisticated manifolds leverages multi-axis CNC machining centers that can approach the workpiece from multiple angles without repositioning. This capability is essential for creating the complex internal networks and external features characteristic of modern CNC Machined Manifold designs. Five-axis machining simultaneously controls three linear axes and two rotational axes, enabling complete machining of complex geometries in single setups.

This approach is particularly valuable for Robotic CNC Machines That Weld Exhaust Manifold applications, where complex tubular structures require precise joint preparation and welding access. The integration of robotics with CNC precision ensures consistent weld quality and dimensional accuracy in high-temperature exhaust components.

Quality Assurance and Testing

CNC Machined Manifold Manufacturer operations incorporate comprehensive quality control processes throughout production. In-process verification using touch probes and laser measurement systems ensures dimensional accuracy at critical machining stages, while final inspection includes flow testing, pressure testing, and surface finish analysis to validate performance specifications.

For Wholesale CNC Machined Manifold suppliers serving volume markets, statistical process control monitors production consistency and identifies potential deviations before they impact quality. This systematic approach to quality management ensures that every component, whether sourced from a CNC Machined Manifold China facility or domestic production, meets the same rigorous standards.

Regional Manufacturing Capabilities

Texas and Houston Manufacturing Hub

The concentration of Railroads Transparent Manifolds CNC Machining Houston and Railroads Transparent Manifolds CNC Machining Texas facilities reflects the region’s strong industrial base and transportation infrastructure. Houston’s manufacturing ecosystem supports energy, transportation, and industrial sectors with comprehensive CNC Machined Manifold Parts Manufacturing capabilities that serve both domestic and international markets.

Railroads Transparent Manifolds CNC Plastic Machining Houston specialists leverage the region’s petrochemical expertise to source advanced engineering plastics with optimal properties for specific applications. Similarly, Railroads Transparent Manifolds CNC Plastic Machining Texas facilities benefit from the state’s central logistics position for distributing components to railroad maintenance facilities nationwide.

Global Manufacturing Network

The global landscape for CNC Machined Manifold production includes specialized facilities worldwide, each offering unique capabilities and advantages. While CNC Machined Manifold China operations often provide cost advantages for high-volume production, domestic manufacturers offer shorter lead times and greater flexibility for custom projects and lower volumes.

Businesses seeking CNC Machined Manifold For Sale options should evaluate suppliers based on technical capabilities, quality systems, and industry experience rather than location alone. The most successful CNC Machined Manifold Factory operations combine advanced equipment with engineering expertise to deliver optimal solutions for specific application requirements.

Specialized Manifold Applications and Manufacturing Solutions

Transparent Manifolds for Monitoring and Maintenance

Railroads Transparent Manifolds CNC Machining addresses the unique requirement for visual system monitoring in safety-critical applications. These components, typically machined from high-strength transparent polymers, allow maintenance personnel to observe fluid flow, detect air bubbles, and identify contamination without disassembly or invasive inspection procedures.

The manufacturing process for Railroads Transparent Manifolds CNC Plastic Machining requires specialized expertise in machining optical-grade materials without introducing stress cracks or surface defects that could compromise clarity or structural integrity. Precision machining ensures leak-free sealing surfaces and proper port alignment while maintaining the optical qualities necessary for visual inspection.

High-Performance and Custom Applications

The CNC Machined Intake Manifold market serves both OEM production and aftermarket performance sectors, where optimized designs can significantly impact engine output and efficiency. Performance applications often feature variable-length runner designs, optimized plenum volumes, and precision-machined mounting surfaces for fuel injection systems – all achievable through advanced CNC Machining Manifold Block capabilities.

For enthusiasts and small-volume applications, Home CNC Machining Intake Manifold projects demonstrate the accessibility of CNC technology, though professional manufacturing typically delivers superior results for demanding applications. The availability of Wholesale CNC Machining Manifold Block options makes performance upgrades more accessible while maintaining quality standards.

Robotic Welding Integration

Robotic CNC Machines That Weld Exhaust Manifold components represent the integration of additive and subtractive manufacturing processes. These systems typically machine mating surfaces and critical features before performing automated welding operations to assemble complex tubular structures. Applications like Robotic CNC Machines That Weld Exhaust Manifold For Honda Pilot systems demonstrate the precision achievable through integrated robotic manufacturing.

This hybrid approach combines the design flexibility of fabricated structures with the precision of machined features, creating optimized components that balance performance, durability, and manufacturing efficiency. The automation of both machining and welding operations ensures consistent quality in high-volume production environments.

Economic and Operational Advantages

Lifecycle Cost Benefits

While the initial investment in CNC Machined Manifold components may exceed conventionally manufactured alternatives, the total cost of ownership typically favors precision-machined solutions. The superior durability, reduced maintenance requirements, and improved system efficiency of precision manifolds deliver significant operational savings over equipment lifespan.

For businesses evaluating CNC Machined Manifold For Sale options, considerations should include not only purchase price but also installation costs, maintenance intervals, system efficiency, and service life. The precision fit of CNC Machining Manifold Block components reduces installation time and eliminates custom fitting or modification during assembly.

Supply Chain and Availability

The established network of CNC Machined Manifold Supplier and Wholesale CNC Machined Manifold sources ensures reliable availability for both routine maintenance and emergency replacement scenarios. Digital manufacturing capabilities enable rapid production of replacement components, reducing equipment downtime and associated production losses.

Global manufacturing resources including CNC Machined Manifold China facilities provide cost-effective solutions for standard components, while domestic CNC Machined Manifold Manufacturer operations offer responsive service for custom applications and quick-turnaround requirements. This diversified supply chain ensures optimal solutions for varying project requirements and timelines.

Future Trends in Manifold Design and Manufacturing

Advanced Materials and Hybrid Manufacturing

The future of CNC Machined Manifold technology points toward increased use of advanced materials including high-temperature composites, engineered polymers, and metal matrix composites. These materials offer improved performance characteristics while presenting new machining challenges that require specialized tooling and processes.

Hybrid manufacturing approaches that combine additive and subtractive processes will enable more complex internal geometries and integrated features. This evolution will further optimize manifold performance while reducing weight and material usage through structurally efficient designs impossible to achieve with conventional manufacturing.

Digital Integration and Smart Manufacturing

The integration of CNC Machined Manifold components with digital monitoring and control systems represents the next frontier in manifold technology. Smart manifolds with embedded sensors will provide real-time performance data, enable predictive maintenance, and automatically adjust system parameters for optimal operation under varying conditions.

Manufacturing evolution will see increased automation through lights-out production facilities and AI-driven optimization of machining parameters. These advances will further improve the consistency and efficiency of CNC Machining Manifold Block production while reducing manufacturing lead times and costs.

Conclusion: Strategic Advantages of CNC Machined Manifolds

The applications of engine manifolds span critical systems across transportation, industrial, and energy sectors, with performance requirements continuously evolving toward higher efficiency and reliability. CNC Machined Manifold manufacturing has emerged as the enabling technology that meets these demanding requirements while providing economic manufacturing solutions across production volumes.

From specialized applications like Railroads Transparent Manifolds CNC Machining to high-volume automotive components, the precision, flexibility, and consistency of CNC machining deliver measurable advantages in performance, durability, and total cost of ownership. As manufacturing technology continues to advance, the capabilities for producing increasingly sophisticated manifold designs will expand, driving further improvements in system efficiency and functionality.

Businesses seeking CNC Machined Manifold Supplier partnerships should prioritize technical capabilities, quality systems, and industry-specific experience to ensure optimal solutions for their specific application requirements. The strategic implementation of precision-manufactured manifolds represents a significant opportunity to enhance system performance, reduce operating costs, and improve overall equipment reliability across diverse industrial applications.

Reviews

There are no reviews yet.