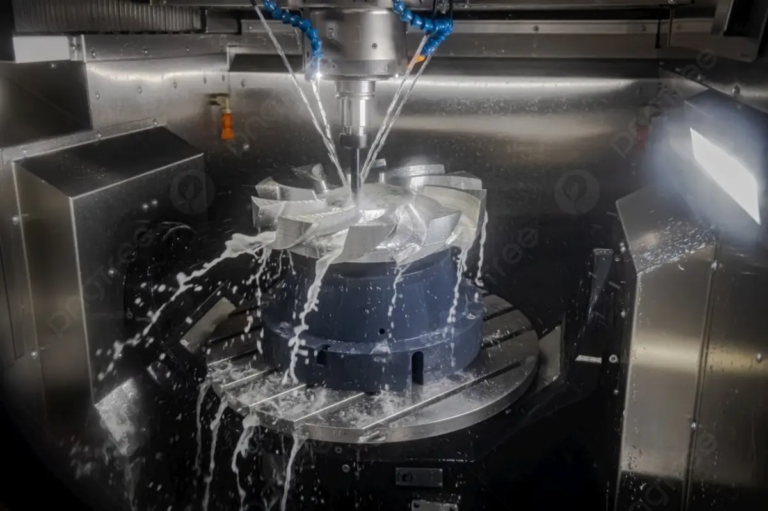

In the world of CNC machining, three-axis CNC vertical machining centers (VMCs) have been the main one for many years. However, in recent years, the need for improved accuracy and versatility has led to the development of 5-axis CNC machining centers. In this blog post, we will explore the benefits of a 3-axis CNC vertical machining center and why it remains a popular choice among manufacturers.

One of the main advantages of a 3-axis CNC VMC is its reliability and simplicity. With only three axes to control, the machine is less prone to errors and is easier to maintain than a five-axis machine. This means greater uptime and reduce downtime, thereby improving productivity and cost reduction.

Another important advantage of 3-axis CNC VMC is its flexibility. These machines can be used in a wide range of applications from milling and drilling to turning and grinding. This versatility makes them an excellent choice for manufacturers with different product lines or need to process different materials.

In addition to its reliability and flexibility, the 3-axis CNC VMC is also known for its ease of operation. The control system is usually easy to learn, and the machine is designed for easy setup and operation. This reduces the need for extensive training that can save time and resources.

A further benefit of a 3-axis CNC VMC is its affordability. Purchasing and maintaining 3-axis CNC VMCs are usually cheaper than five-axis machines. This is an attractive option for small and medium-sized manufacturers or manufacturers with limited budgets.

In addition to these advantages, the 3-axis CNC VMC also offers excellent surface surface and accuracy. The machine’s control system allows precise movement, resulting in high-quality finishes and accurate tolerances.

In short, 3-axis CNC VMC is a popular choice for manufacturers due to its reliability, flexibility, ease of operation, affordability, and excellent finish and accuracy. While five-axis machines may offer additional features, a 3-axis CNC VMC remains a trusted and reliable option for many manufacturers.

FAQ:

Q: What are the benefits of 3-axis CNC VMC?

A: The benefits of a 3-axis CNC VMC include its reliability, flexibility, ease of operation, affordability, and excellent finish and accuracy.

Q: Is 3-axis CNC VMC suitable for all types of manufacturing?

A: Yes, 3-axis CNC VMCs can be used in a wide range of applications including milling, drilling, turning and grinding.

Q: Is 3-axis CNC VMC more expensive than 5-axis CNC machining centers?

A: Generally, 3-axis CNC VMCs purchased and maintained are at a lower price than 5-axis CNC machining centers.

Q: What is the finish and accuracy of a 3-axis CNC VMC?

A: 3-axis CNC VMC provides excellent surface surface and accuracy thanks to its precise control system.