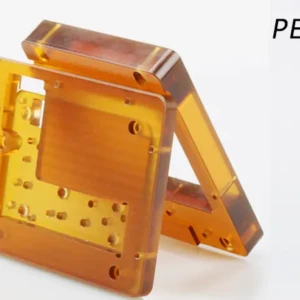

Custom Automotive Engine Oil Pan CNC Machining Service

— High-Precision, Tailor-Made Metal Components for Automotive and Industrial Applications —

Product Overview

Our Custom Automotive Engine Oil Pan CNC Machining Service is designed for clients seeking high-quality, precision-engineered metal components. Leveraging advanced Computer Numerical Control (CNC) technology, we offer bespoke manufacturing solutions for Automotive Engine Oil Pans and a wide range of custom metal parts. Our service is ideal for automotive, industrial, and machinery sectors that demand accuracy, durability, and customization.

Key Features

- Precision Engineering: Utilizing state-of-the-art CNC machining centers, we achieve tight tolerances and complex geometries that meet or exceed international standards.

- Material Versatility: We process a vast array of metals including aluminum alloys, stainless steel, carbon steel, titanium, and other specialized materials to fit your specific requirements.

- Flexible Customization: Whether you provide detailed CAD drawings, samples, or conceptual designs, our engineering team works closely with you to deliver components tailored to your application.

- Surface Finishing Options: A variety of finishes are available, such as anodizing, powder coating, painting, sandblasting, polishing, and electroplating, enhancing both appearance and performance.

- Batch Production Capability: From rapid prototyping to mass production, our flexible manufacturing system adapts to both small and large order volumes.

CNC Machining Process

CNC machining is an advanced manufacturing method that uses computer-controlled tools to remove material from a solid workpiece, creating parts with exceptional precision and repeatability. Our process includes:

- Design Consultation: We review your technical drawings or samples, discuss critical features, and recommend optimal manufacturing solutions.

- Material Selection: Based on your performance, cost, and application needs, we suggest the best material options.

- Programming and Tooling: Our engineers create detailed CNC programs and select specialized cutting tools to ensure accuracy and efficiency.

- Machining Operations: The workpiece is processed through milling, turning, drilling, tapping, and other operations as needed.

- Quality Inspection: Each part undergoes rigorous dimensional and functional checks using advanced metrology equipment.

- Surface Treatment: Parts are finished according to your specifications, ensuring corrosion resistance, improved aesthetics, and extended service life.

- Packaging and Delivery: Secure packaging ensures safe transit, and we offer flexible shipping options worldwide.

Advantages of CNC Machining for Automotive Engine Oil Pans

- High Dimensional Accuracy: CNC machining guarantees precise fitment and sealing, critical for engine oil containment and performance.

- Consistent Quality: Automated controls and repeatable processes ensure every part meets the same high standards, regardless of batch size.

- Complex Design Capability: Intricate features, undercuts, and varying wall thicknesses can be realized with ease, accommodating both standard and innovative designs.

- Material Efficiency: Subtractive manufacturing minimizes waste and allows for the use of high-strength, lightweight alloys.

- Rapid Turnaround: With streamlined workflow and skilled operators, we deliver prototypes and production runs on tight schedules.

Applications

Our CNC machined Automotive Engine Oil Pans and metal components are widely used in:

- Automotive Industry: Passenger cars, trucks, motorcycles, racing vehicles, and specialty vehicles.

- Industrial Machinery: Compressors, generators, pumps, and heavy equipment.

- Aerospace and Defense: Where precision and reliability are paramount.

- Marine and Agricultural Equipment: Durable components for harsh environments.

- Custom Engineering Projects: One-off or low-volume production for research, prototyping, or restoration.

Quality Assurance

We are committed to delivering products that adhere to the highest standards of quality and reliability. Our quality management system includes:

- ISO 9001 Certification: All processes are governed by internationally recognized quality control standards.

- Comprehensive Inspection: Every batch is inspected for dimensional accuracy, surface integrity, and material properties.

- Traceability: All materials and processes are fully documented, ensuring accountability and transparency.

- Continuous Improvement: We invest in staff training and equipment upgrades to maintain cutting-edge capabilities.

Surface Finishing Options

To meet diverse functional and aesthetic needs, we provide a full range of surface treatments, including but not limited to:

- Anodizing: Enhances corrosion resistance and offers various color options for aluminum parts.

- Powder Coating and Painting: Provides durable, attractive finishes suitable for demanding environments.

- Electroplating: Adds a protective or decorative metal layer, such as zinc or nickel.

- Polishing and Sandblasting: Achieves smooth or matte finishes according to design intent.

- Custom Marking: Laser engraving or silk-screen printing for branding or identification.

Customization Process

- Inquiry and Quotation: Send us your requirements, including drawings, specifications, and quantities. We provide a detailed quotation promptly.

- Design Optimization: Our engineers review your design for manufacturability, recommending improvements if needed.

- Sample Production: Upon request, we produce and ship samples for your evaluation and approval.

- Batch Manufacturing: Once samples are approved, we proceed with full-scale production, maintaining consistent quality throughout.

- Logistics and Support: We handle all logistics, including export documentation, customs clearance, and after-sales support.

Why Choose Us?

- Technical Expertise: Decades of experience in CNC machining and component manufacturing.

- Customer-Centric Service: Dedicated project managers provide responsive communication and technical support from start to finish.

- Competitive Pricing: Efficient production and material sourcing keep costs under control without compromising quality.

- Global Reach: We serve clients worldwide, with proven export experience and reliable shipping partners.

- Sustainability: We implement environmentally responsible practices, minimizing waste and energy consumption.

Frequently Asked Questions

Q: What information do I need to provide for a quotation?

A: Please provide 2D/3D drawings (in formats such as PDF, DWG, STEP, or IGES), material requirements, surface finish preferences, quantity, and any special instructions.

Q: What is the typical lead time?

A: Lead times vary depending on complexity and volume. Prototypes are usually delivered within 7–15 days; mass production orders may require 20–35 days.

Q: Can you assist with design or reverse engineering?

A: Yes, our engineering team can help optimize your design for manufacturability or create models from existing parts.

Q: How do you ensure confidentiality of my designs?

A: We sign NDA agreements upon request and strictly protect all customer intellectual property.

Q: What are your payment terms?

A: We offer flexible payment options, including T/T, L/C, and PayPal for sample orders.

Contact Us

Ready to start your custom CNC machining project or need more information?

Contact our sales and engineering team today for a fast, professional response and a free quotation tailored to your needs.

Custom Automotive Engine Oil Pan CNC Machining Service

Your trusted partner for high-precision, customized metal components.

If you need this content expanded further or split into additional sections for a longer format, please let me know!

Reviews

There are no reviews yet.