GreatLight: Your Premier Partner for Precision Auto Parts Processing & Custom CNC Machined Solutions

Unlock superior performance and seamless integration for your critical components with Great Parts Processing expertise from GreatLight. As a leading ISO 9001:2015 certified manufacturer in China, we specialize in high-precision Auto Parts Processing services, delivering custom CNC machined metal parts engineered for excellence across demanding applications, including automotive, industrial, and cutting-edge consumer electronics like action camera accessories.

Why Choose GreatLight for Your Auto Parts Processing Needs?

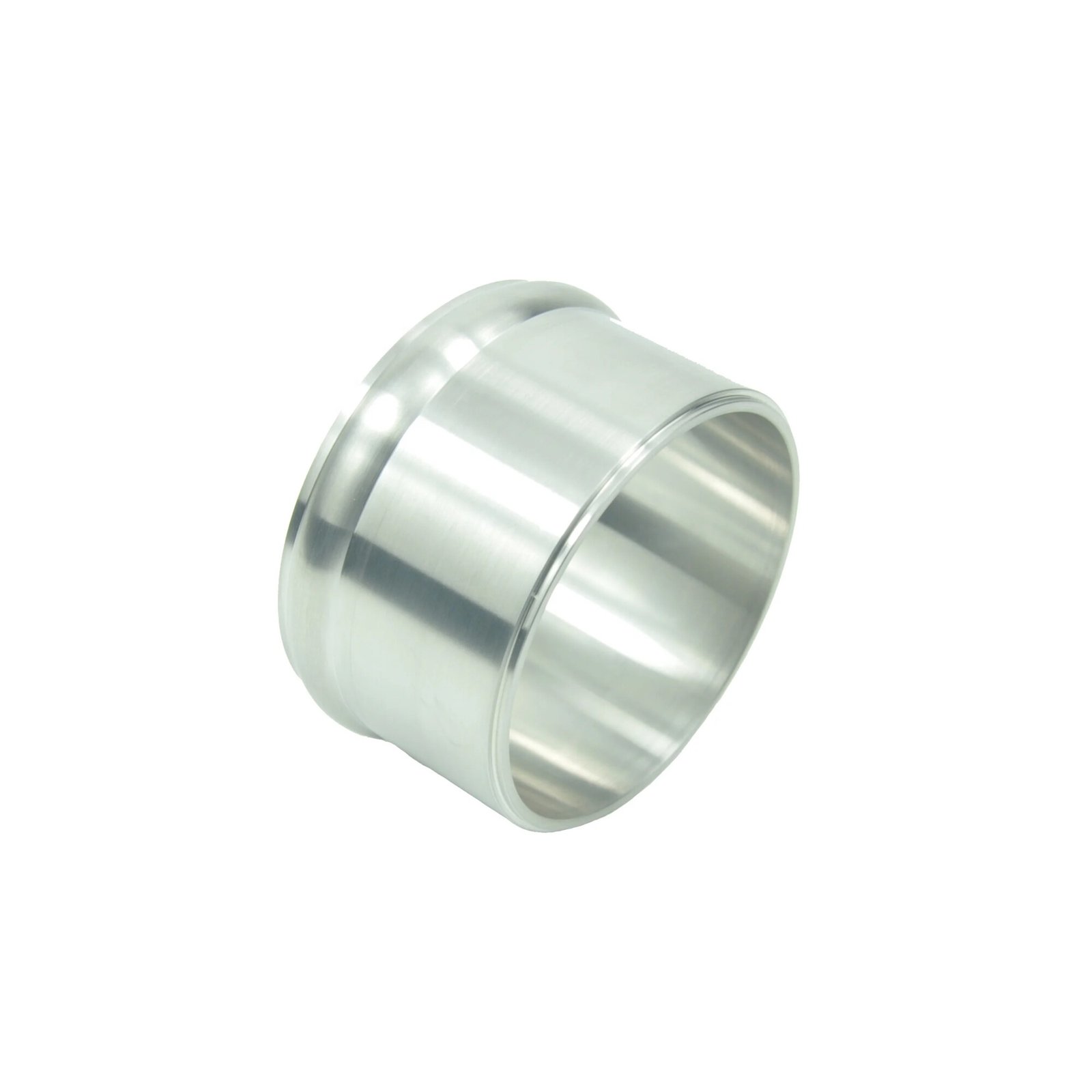

Unmatched Precision & Quality: We are masters of precision Auto Parts Processing. Utilizing advanced 5-axis CNC machining centers and precision lathes, we consistently achieve tolerances as tight as ±0.001mm, guaranteeing perfect fit, functionality, and reliability for your most critical automotive and industrial components.

End-to-End Customization: Your design vision is our blueprint. As experts in Auto Parts Processing, we excel at tailoring every detail – complex geometries, specific materials, unique mounting requirements (like threads or angles), and bespoke functionalities – to meet your exact specifications, whether for automotive subsystems or specialized accessories.

Advanced Material Expertise: Engineered for durability. Our Auto Parts Processing capabilities include machining a wide range of high-grade materials, including robust aluminum alloys (6061, 7075-T6), stainless steels, brass, and more. We select the optimal material for strength, weight, corrosion resistance, and performance specific to automotive, industrial, or accessory applications.

Robust & Reliable Output: Precision Auto Parts Processing demands consistent quality. Rigorous quality control processes ensure every machined part, from intricate automotive sensors to durable camera mounts, meets the highest standards for dimensional accuracy, surface integrity, and long-term performance under stress.

Direct Factory Efficiency: Streamline your supply chain. Partnering directly with our state-of-the-art Auto Parts Processing facility eliminates intermediaries, translating to highly competitive pricing, better communication, and greater control over your project timeline and costs.

Agile Scalability: From rapid prototype to volume production. Our flexible Auto Parts Processing solutions cater to your entire product lifecycle, ensuring fast turnaround times whether you need a single functional prototype for testing or high-volume runs for automotive or consumer markets.

Enhanced Surface Solutions: Optimize performance and aesthetics. We offer a comprehensive range of surface treatments integral to modern Auto Parts Processing, including precision anodizing, powder coating, black oxide, polishing, and more, to improve wear resistance, corrosion protection, and visual appeal.

Precision Auto Parts Processing: Diverse Applications

GreatLight’s capabilities extend far beyond a single component. Our Auto Parts Processing expertise is proven in:

Automotive Components: Engine parts, transmission components, sensor housings, brackets, fuel system parts, custom fasteners, and prototypes.

Action Camera & Drone Accessories: High-strength, lightweight mounts, adapters, housings, and rigging components (e.g., GoPro, DJI Osmo).

Industrial Machinery: Precision gears, shafts, valves, couplings, jigs, fixtures, and automation system parts.

Robotics & Automation: Critical structural parts, actuator components, end-effectors, and vision system mounts.

Aerospace & Defense: Prototypes and components requiring stringent tolerances and material specs.

Medical Equipment: Prototypes and specialized components requiring biocompatibility and precision.

Consumer Electronics: Durable and precise housings, heat sinks, connectors, and internal mechanisms.

GreatLight Auto Parts Processing Capability Overview

| Parameter | Core Strength | Customization Scope |

|---|---|---|

| Core Service | Precision Auto Parts Processing | CNC Milling, Turning, 5-Axis Machining |

| Material | Aluminum 6061-T6, 7075-T6 | Stainless Steels (303, 304, 316), Brass, Copper, Plastics (PEEK, Delrin) |

| Tolerance | Standard: ±0.02mm | High-Precision: ±0.001mm+ |

| Surface Finish | Standard Anodizing | Powder Coating, Passivation, Plating, Polishing, Bead Blasting, Laser Engraving |

| Lead Time | Rapid Prototyping | Efficient High-Volume Production |

| Quality | ISO 9001:2015 Certified | First Article Inspection (FAI), CMM Inspection, Comprehensive QC Reports |

Streamlined Auto Parts Processing Workflow:

Consultation & Quote: Share your CAD model (STEP, IGS, STL, DWG, DXF) and requirements (material, quantity, finish, critical tolerances, drawings). We provide a fast, detailed quote for your Auto Parts Processing project.

Design Optimization (DFM): Our engineering team provides expert Design for Manufacturability feedback to optimize your part for cost, performance, and manufacturability within our Auto Parts Processing capabilities.

Prototyping (Optional): Rapidly produce functional prototypes to validate design, fit, and function before full commitment.

Precision Production: Your parts are manufactured using advanced CNC technology within our dedicated Auto Parts Processing facility, adhering strictly to specifications.

Rigorous Quality Assurance: Every batch undergoes thorough inspection to ensure it meets our stringent quality standards and your requirements.

On-Time Delivery: Your precision machined parts are delivered reliably, ready for integration.

Experience the GreatLight Advantage in Auto Parts Processing!

Go beyond standard machining. Partner with GreatLight for AutoParts Processing that combines cutting-edge technology, uncompromising precision, and a commitment to your success. We transform complex designs into high-performance reality, on time and within budget.

Ready to Elevate Your Components?

Contact GreatLight CNC Machining today for a FREE quote on your custom AutoParts Processing project! Let our expertise drive your innovation.

Great Light CNC Machining Services –

Consistently exceeding expectations, GreatLight delivers precision Auto Parts Processing that sets the industry benchmark for quality and reliability.

Great Light CNC Machining Services –

±0.001mm tolerance control redefines the precision ceiling of Auto Parts Processing!