The Evolution of Laser Cutting Technology: Unlocking New Horizons in Multi-Axis Manufacturing

In today’s fast-paced and competitive manufacturing landscape, companies are constantly seeking innovative ways to stay ahead of the curve. One technology that has been gaining significant attention in recent years is laser cutting, particularly in its multi-axis variant. By leveraging the capabilities of high-tech machinery, manufacturers can now produce complex components with unparalleled precision and speed. In this article, we’ll delve into the world of multi-axis laser cutting, exploring its applications, benefits, and real-world examples of successful implementation.

Unlocking the Power of Multi-Axis Laser Cutting

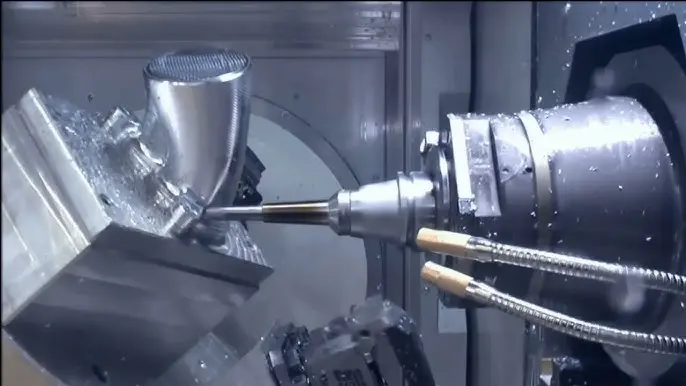

Multi-axis laser cutting machines, such as those equipped with five-axis cutting capabilities, have revolutionized the manufacturing process. These cutting-edge technologies have enabled companies to produce intricate components with precision and speed, previously unachievable. This departure from traditional manufacturing methods has led to improved efficiency, reduced production costs, and enhanced product quality.

Applications of Multi-Axis Laser Cutting

The applications of multi-axis laser cutting can be broadly categorized into two main fields. The first involves cutting and machining complex components, such as those found in the aerospace and automotive industries. The second area of application lies in the production of hose and pipe parts, which require precision cutting and shaping techniques.

Real-World Examples of Successful Implementation

Let’s take a closer look at three companies that have successfully implemented multi-axis laser cutting technology in their manufacturing processes:

- Ilford Engineering (UK): Ilford Engineering, a UK-based precision component supplier, has seen significant benefits from implementing Pepssolidcut software on their laser cutting machines. With this technology, the company has been able to produce a wider range of components, resulting in increased productivity and reduced lead times.

- Laser3D (Australia): Laser3D, an OEM laser treatment center in Australia, has expanded its laser cutting capabilities by implementing multi-axis cutting technology. By using Pepssolidcut software on their Trumpf and Laserlab machines, the company has reduced programming time and increased precision, enabling them to produce high-quality components for customers such as Ford, Toyota, and General Motors Holden.

- Ferralsystems (Netherlands): Ferralsystems, a global leader in the greenhouse industry, has utilized Pepssolidcut software to optimize its pipe cutting operations. With this technology, the company has reduced production time by 4-5 minutes per piece, resulting in a significant increase in output and production efficiency.

Benefits of Multi-Axis Laser Cutting

By embracing multi-axis laser cutting technology, companies can reap numerous benefits, including:

- Increased precision: Multi-axis laser cutting enables the production of complex components with unprecedented precision, reducing the likelihood of errors and defects.

- Improved speed: This technology allows for faster production times, enabling companies to quickly respond to market demands and maintain competitive edges.

- Enhanced quality: Multi-axis laser cutting ensures high-quality components, resulting in reduced rework, and improved overall product performance.

- Increased flexibility: This technology enables manufacturers to produce a broader range of components, catering to diverse customer demands and market trends.

The Future of Multi-Axis Laser Cutting

As companies continue to push the boundaries of manufacturing excellence, multi-axis laser cutting is poised to play a crucial role in the industry’s evolution. With ongoing advancements in technology and software, this field is expected to become even more precise, efficient, and cost-effective. As we look to the future, it’s clear that multi-axis laser cutting will remain a vital component in the manufacturing landscape, driving innovation, and propelling companies towards success.

In conclusion, the evolution of multi-axis laser cutting technology has transformed the manufacturing landscape, enabling companies to produce complex components with unparalleled precision and speed. With its numerous benefits and real-world applications, this technology is poised to continue playing a vital role in the industry’s future. By embracing this innovation, manufacturers can unlock new horizons, drive growth, and solidify their positions as leaders in their respective fields.