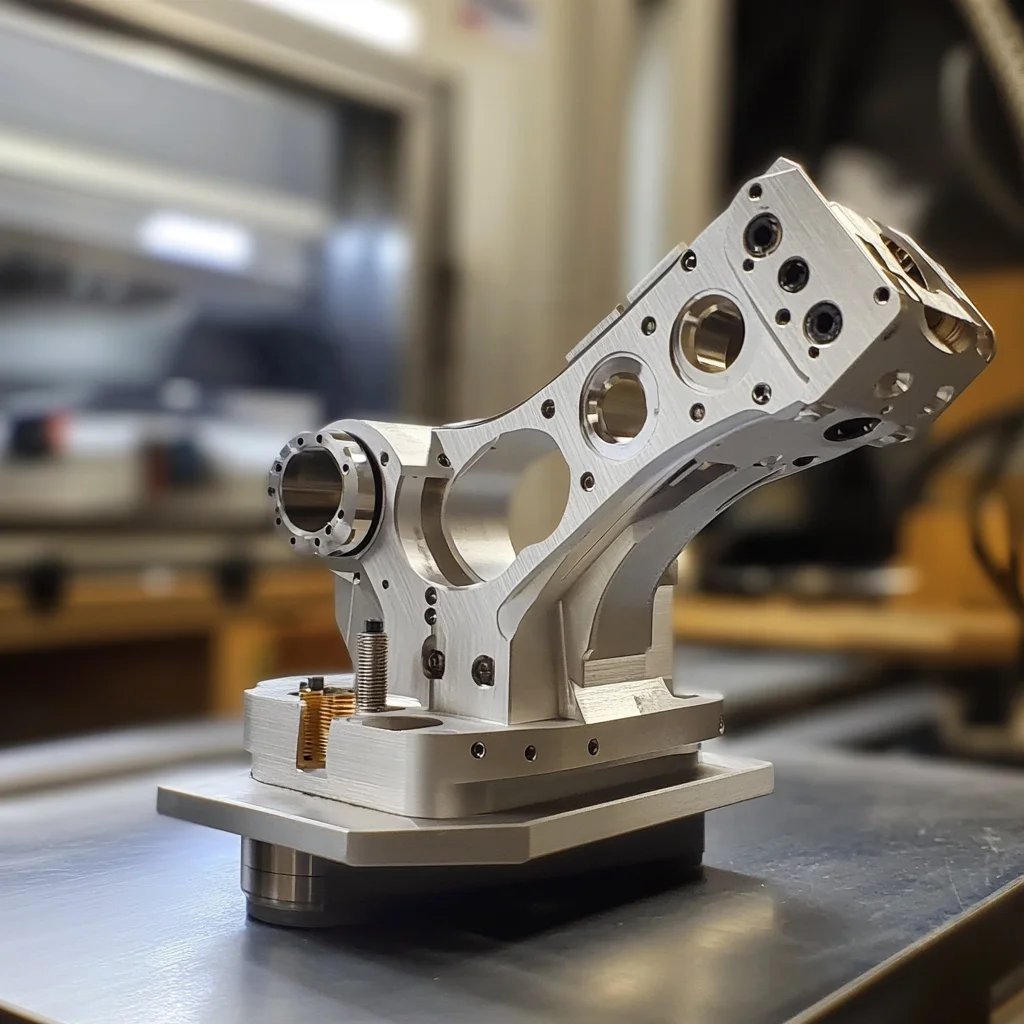

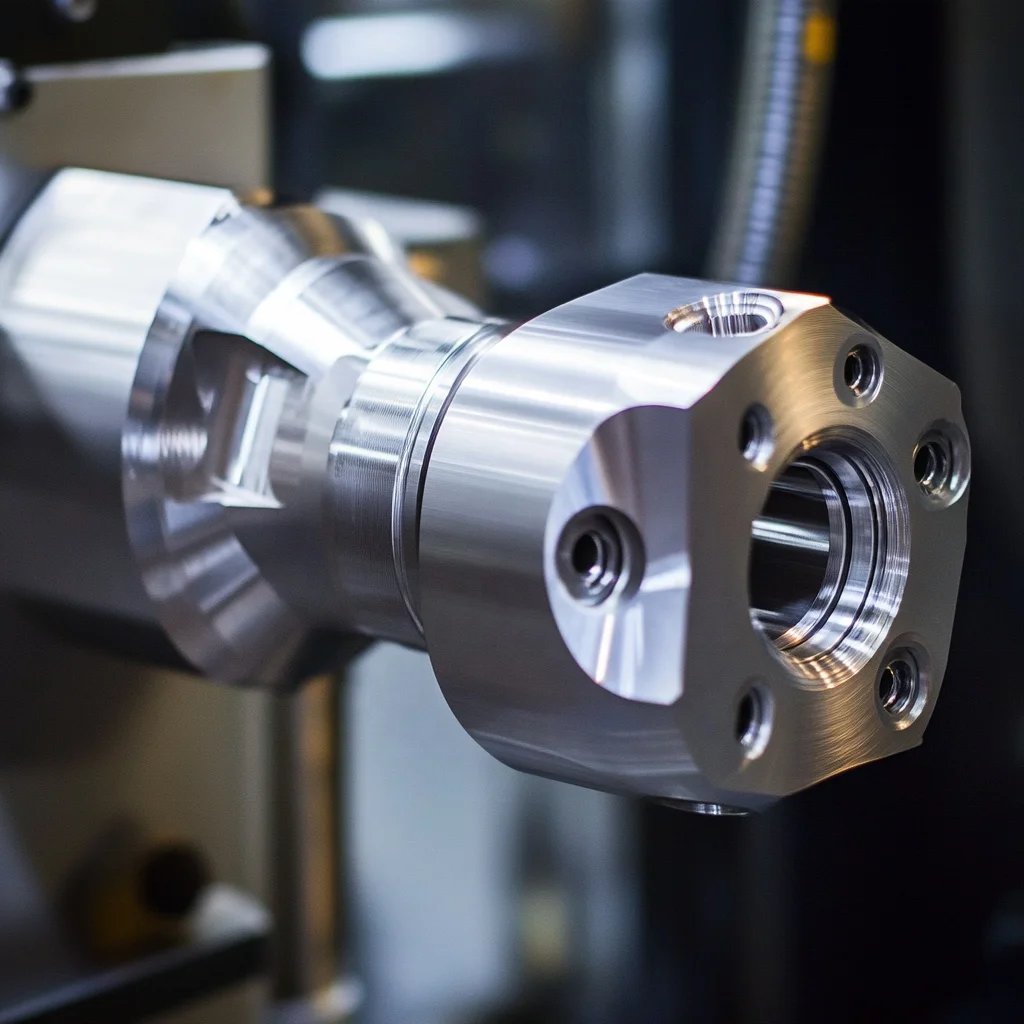

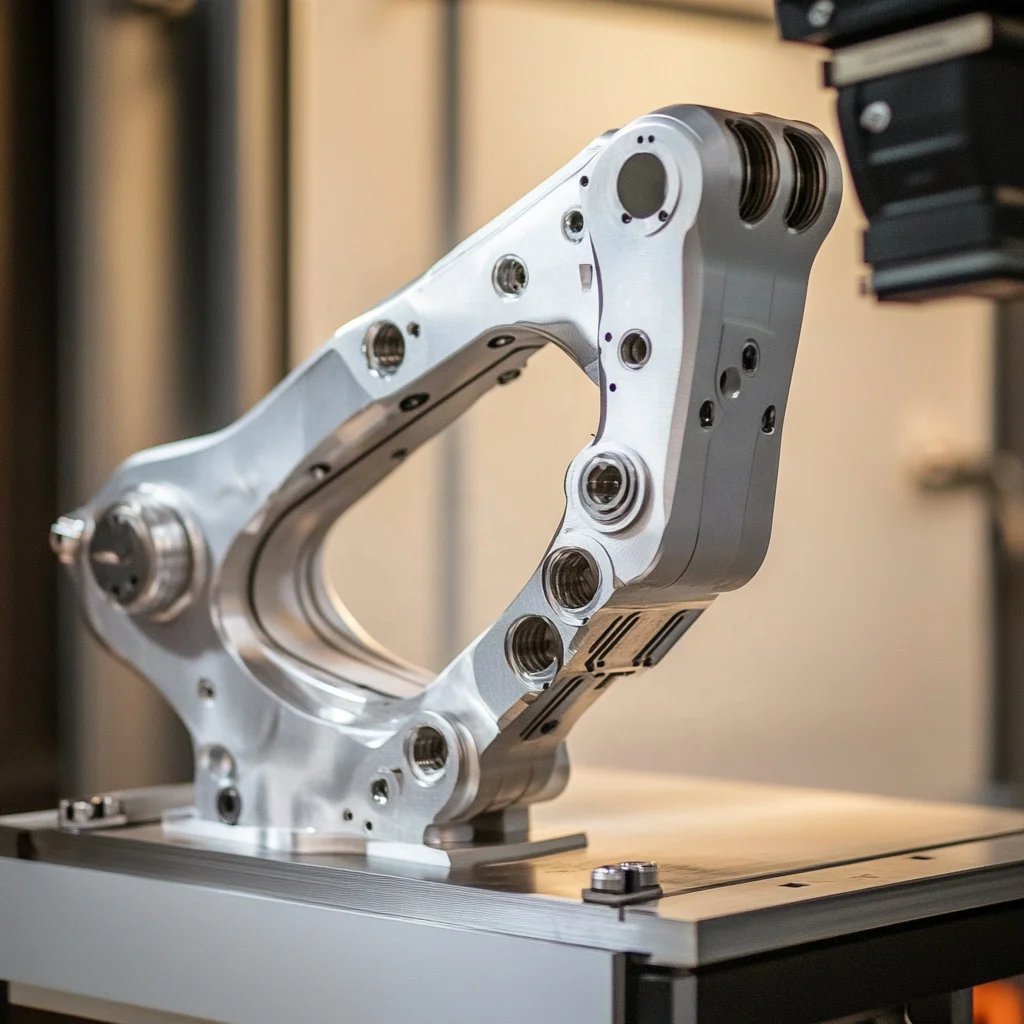

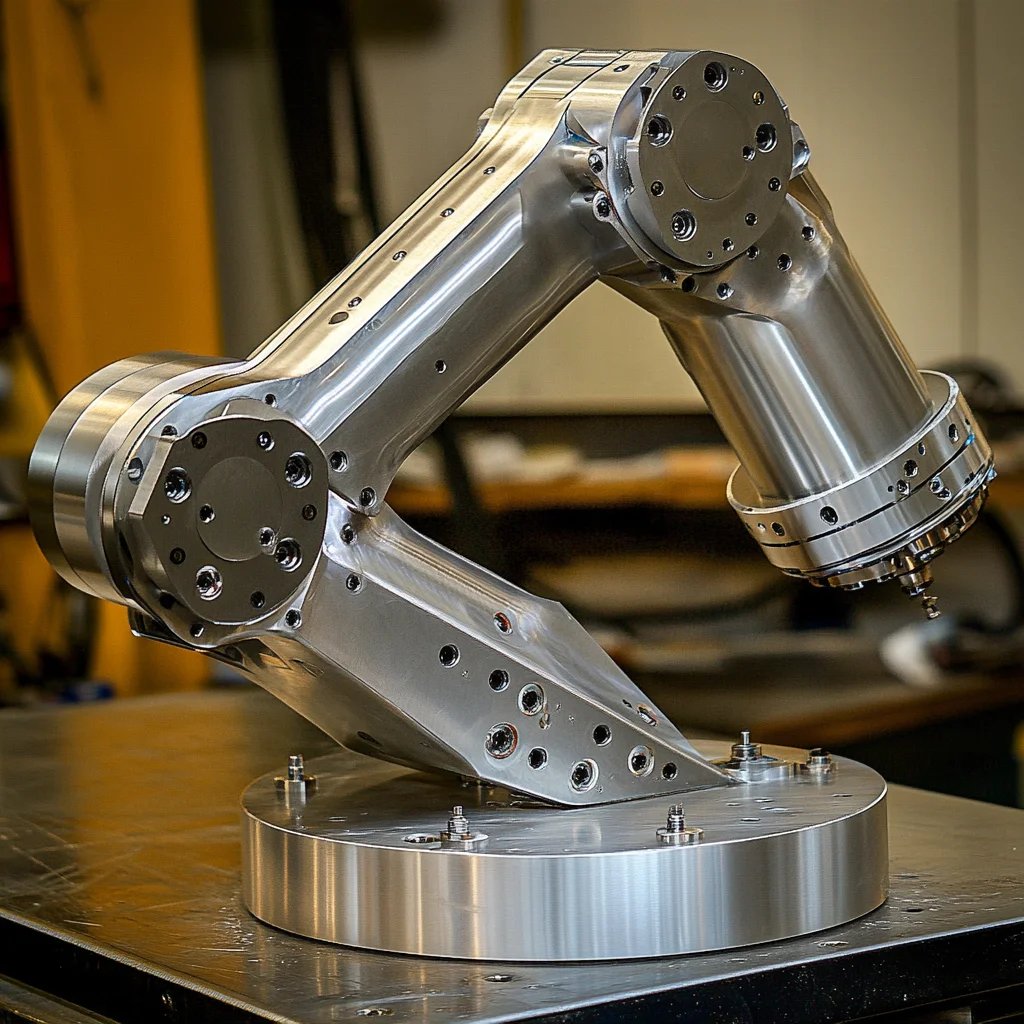

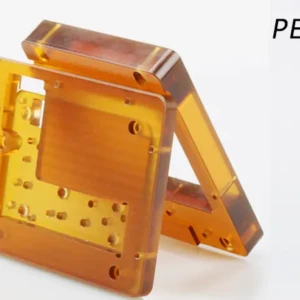

Custom 5 Axis CNC Machined Parts for Industrial Robot Arm Joints

Overview

GreatLight, an ISO 9001:2015‑certified precision CNC machining factory located in Dongguan, China, specializes in high‑accuracy 3‑, 4‑ and 5‑axis CNC machining and turning services for the robotics and automation industry. With a tolerance of ± 0.001 mm and a rapid‑prototype turnaround, we deliver custom metal and plastic parts that meet the exacting standards of modern automation equipment manufacturers.

Our state‑of‑the‑art 5‑axis CNC machines, in combination with advanced motion control and real‑time monitoring, enable us to produce complex robot‑arm joint components with superior surface finish, dimensional fidelity, and repeatability.

Whether you need a single prototype or a high‑volume production run, GreatLight offers seamless collaboration, flexible pricing, and a comprehensive service package that covers design, machining, quality control, logistics, and post‑sales support.

| Key Attribute | Specification |

|---|---|

| Manufacturing Process | CNC Machining |

| Material Capabilities | Aluminum, Brass, Bronze, Copper, Hardened Metals, Precious Metals, Stainless Steel, Steel Alloys |

| Place of Origin | Guangdong, China (Main Facility) |

| Machining Types | Broaching, Drilling, Etching / Chemical Machining, Laser Machining, Milling, Turning, Wire EDM, Rapid Prototyping |

| Micro Machining | Supported |

| Minimum Order Quantity (MOQ) | 1 piece |

| Part Size | Fully Customizable |

| Standard Delivery Time | 30 Days |

| Quality Standard | High Quality, ISO 9001:2015 Certified |

| Packaging & Delivery | |

| Selling Units | Single item / Batch production |

| Lead Time by Quantity | 1 – 1000 pieces: 30 days > 1000 pieces: To be negotiated |

| Service Features | • Design for Manufacturing (DFM) Feedback

• Prototype to Full Production Runs • Comprehensive In-House Quality Inspection |

Core Features

| Feature | Detail |

|---|---|

| 5‑Axis Machining | Full 5‑axis capability allows complex geometries, internal channels, and high‑precision offsets. |

| Tolerance | ± 0.001 mm (ISO tolerances) on all critical dimensions. |

| Surface Finish | 0.05 µm Ra achievable on polished surfaces; 0.2 µm Ra on standard finish. |

| Material Library | Stainless steel, aluminium alloys, titanium, Inconel, high‑strength plastics (PEEK, polycarbonate), composites. |

| CAD/CAM Compatibility | CAD import (IGES, STEP, STL, DWG) and CAM support for all major software (NX, SolidWorks, Mastercam). |

| Rapid Prototyping | Turn‑around from design to finished part in 2–3 days for prototypes. |

| Batch Production | Up to 10,000 parts per batch with consistent quality. |

| Quality Assurance | In‑process measurement, laser scanning, CMM verification, final inspection. |

| Delivery | 3–5 days for small batches, 2–3 weeks for large volumes; on‑time delivery 99 % SLA. |

| After‑Sales | 24/7 technical support, adjustment services, warranty on machining defects. |

Suitability & Applications

- Robotics & Automation – Joint housings, bearing plates, torque‑transmission components, mounting brackets.

- Industrial Machinery – Actuator housings, gearboxes, precision sliders, guide rails.

- Medical Devices – Surgical Robot Arm Joints, implantable components requiring high biocompatibility.

- Aerospace & Defense – Lightweight, high‑strength joint parts for robotic manipulators and handling systems.

- Automotive – Actuator assemblies, servo‑motor housings, safety interlock components.

Our 5‑axis machining technology is particularly advantageous for parts that feature complex undercuts, internal cavities, or require multi‑angle surface finishes—common in modern Robot Arm Joints.

Quality & Accuracy

- Precision Engineering – All machines are regularly calibrated (± 0.001 mm) using certified gauge blocks and coordinate measuring machines (CMMs).

- Real‑Time Monitoring – Open‑loop feedback and closed‑loop control reduce deviations to within 0.001 mm.

- Quality Control System – ISO 9001:2015 compliance ensures systematic inspection at every stage: raw material inspection → in‑process measurement → final CMM verification → final surface finish inspection.

- Statistical Process Control (SPC) – We employ SPC charts to monitor dimensional stability and surface roughness during production runs.

Parameter Table (Example for a Typical Robot Arm Joints Housing)

| Part Feature | Minimum Value | Maximum Value | Typical Value |

|---|---|---|---|

| Diameter (mm) | 20 | 120 | 55 |

| Wall thickness (mm) | 1.0 | 5.0 | 3.0 |

| Thread pitch (mm) | 1.0 | 5.0 | 1.25 |

| Surface finish (Ra, µm) | 0.2 | 0.05 | 0.05 |

| Material | 316L SS | 7075‑Al | 316L SS |

| Tolerance (± mm) | 0.001 | 0.003 | 0.0015 |

The table can be customized for each specific part.

Material Properties Table

| Material | Density (g/cm³) | Yield Strength (MPa) | Elongation (%) | Hardness (HB) | Corrosion Resistance |

|---|---|---|---|---|---|

| 316L Stainless Steel | 7.97 | 290 | 35 | 190 | Excellent |

| 7075‑Aluminium | 3.01 | 503 | 10 | 155 | Moderate |

| Ti‑6Al‑4V | 4.43 | 900 | 10 | 300 | Excellent |

| PEEK | 1.31 | 70 | 20 | 20 | Excellent |

| Polycarbonate | 1.20 | 40 | 70 | 15 | Moderate |

All materials are sourced from ISO‑certified suppliers and undergo a material approval process before machining.

Machining Instructions (High‑Level Workflow)

- Design Review – Verify CAD model for manufacturability (feature sizes, clearances, tool access).

- Tooling Selection – Choose appropriate end mills, drills, and inserts based on material and geometry.

- Toolpath Generation – Create optimized 5‑axis toolpaths with adaptive machining strategies (high‑speed, low‑speed passes).

- Simulation & Collision Check – Run virtual machining simulations to detect potential collisions or undercuts.

- Prototype Build – Produce a single prototype for dimension and fit verification.

- Iterative Feedback – Adjust toolpaths or design based on prototype results.

- Production Run – Execute production with real‑time monitoring and on‑board inspection.

- Final Inspection – CMM measurement, surface finish verification, and part certification.

- Packaging & Shipping – Secure packaging per ISO 16900; dispatch via SEA/air freight.

Customization Guide

- Design for Manufacture (DFM) Consultation – Our engineers review your CAD files and provide DFM recommendations.

- Material Substitution – Provide a material list; we advise on suitable alternatives that maintain or improve performance.

- Tolerance Mapping – Identify critical dimensions; we set tighter tolerances where necessary.

- Surface Treatment Options – Polishing, anodizing, laser surface texturing.

- Assembly Integration – Design with pre‑assembly in mind; provide clearance and mounting options.

- Prototyping Packages – Rapid prototype at 30 % of production cost; 3‑day turnaround.

Price Advantage

| Volume | Unit Price (USD) | Discount |

|---|---|---|

| 1–10 | 12.50 | 0 % |

| 11–100 | 11.50 | 5 % |

| 101–500 | 10.70 | 10 % |

| 501–2000 | 9.90 | 15 % |

| 2001+ | 9.20 | 20 % |

Our efficient tooling strategy and high machine uptime enable cost‑effective pricing without compromising quality.

Delivery Cycle & On‑Time Performance

- Prototype Delivery – 2–3 days (within China) or 5–7 days (international).

- Small Batch (≤ 200 parts) – 3–5 days.

- Medium Batch (201–2000 parts) – 2–3 weeks.

- Large Batch (2001+ parts) – 3–6 weeks, depending on complexity.

We guarantee 99 % on‑time delivery; any delay is communicated within 24 hours with a revised schedule.

Communication & Technical Support

- Dedicated Account Manager – Single point of contact for all project phases.

- 24/7 Technical Hotline – Phone + WhatsApp + Email.

- Project Management Portal – Real‑time status updates, document sharing, and milestone tracking.

- Engineering Collaboration – CAD file exchange, design reviews, and rapid prototyping feedback.

Technical Capabilities & Equipment

| Equipment | Model | Axis | Max Workpiece Size (mm) | Max Power (kW) | Control System |

|---|---|---|---|---|---|

| Fanuc 5‑Axis | M-3iA | 5 | 600 × 600 × 600 | 25 | FANUC iRVision |

| Haas 5‑Axis | UMC‑4X | 5 | 800 × 800 × 800 | 30 | Haas iNC |

| Siemens 5‑Axis | SINUMERIK 840D | 5 | 1000 × 1000 × 800 | 35 | SINUMERIK 840D |

| Laser Engraver | Trumpf TruLaser 3030 | 2 | 1500 × 1500 | 15 | ECM 3.0 |

| CMM | Hexagon 3D 500 | 3 | 1500 × 1500 × 1500 | – | Hexagon 3D X |

| Surface Roughness Tester | Mitutoyo Surftest 500 | – | – | – | Mitutoyo |

All machines are serviced quarterly and calibrated by certified technicians.

Quality Control System & Certification

- ISO 9001:2015 – Continuous improvement and customer‑centric processes.

- ISO/TS 16949 – Automotive quality management.

- AS‑9100B – Aerospace quality standards.

- ISO 14001:2015 – Environmental management.

- Product Audits – In‑house audits monthly; external audits annually.

- Traceability – 100 % traceability from raw material to finished part.

Confidentiality & Intellectual Property Protection

- Non‑Disclosure Agreements (NDAs) – Mandatory for all client engagements.

- Secure Data Handling – Encrypted cloud storage for CAD files and project data.

- IP Ownership – All designs and intellectual property remain the client’s property (except for standard tooling templates, which are licensed).

- Audit Trail – Detailed logs of all design revisions and machining parameters.

Supply Chain Stability & Risk Management

- Multiple Raw‑Material Sources – Dual‑sourcing for critical alloys to mitigate supply disruptions.

- Inventory Management – Real‑time inventory tracking and safety stock levels.

- Contingency Planning – Alternate suppliers and backup machining sites.

- Insurance – Comprehensive coverage for goods in transit and production downtime.

- Quality Risk Assessment (QRA) – Ongoing risk identification for each project.

Advantages & Selling Points

| Advantage | Why It Matters |

|---|---|

| Ultra‑High Accuracy | Tolerances of ± 0.001 mm ensure perfect fit for Robot Arm Joints, reducing assembly time and enhancing reliability. |

| Fast Turn‑Around | Rapid prototyping in days accelerates product development cycles and market entry. |

| Complex Geometry Capability | 5‑axis machining handles undercuts, internal channels, and multi‑plane surfaces that conventional 3‑axis cannot. |

| Comprehensive Service Portfolio | From design review to final inspection, packaging, and logistics – one‑stop solution. |

| Cost‑Effective Scaling | Tiered discount structure and efficient tooling keep unit costs low even for high volumes. |

| Global Reach | FOB, CIF, and full freight services on all major shipping routes. |

| Technical Excellence | ISO‑certified processes, advanced equipment, and skilled operators guarantee product excellence. |

| Client‑Centric Support | Dedicated account managers, real‑time communication, and post‑sales service ensure client satisfaction. |

Contact & Ordering Information

- Phone (WhatsApp): +86 180 2756 7310

- Email: [email protected]

- Website: glcncmachining.com

GreatLight CNC Machining Center – Leader in CNC Machining, Rapid Prototyping, and Quality Engineering.

Reviews

There are no reviews yet.