Surface treatment is a process method to artificially form a surface layer with different mechanical, physical and chemical properties of the substrate to the surface of the substrate. The treatment of the surface is to respond to resistance to the corrosion of the product, resistance to wear, decoration or other special functional requirements.

A. polishing

Polishing refers to a treatment method that uses mechanical, chemical or electrochemical actions to reduce the roughness of the room surface to obtain a light and flat surface. It is a treatment for modification of the surface of the part using polishing tools and abrasive particles or other polishing environments. Polishing cannot improve the dimensional precision or geometric precision of the room, but aims to obtain a smooth surface or a brilliant mirror, and is sometimes used to eliminate the brilliant (mat). A polishing wheel is generally used as a polishing tool. The polishing wheel is generally made of canvas with several layers, felt or leather, and the sides are tight with metallic circular plates, and the rims are covered with an abrasive polishing agent and micropourb fat. During polishing, the rotary rotary polishing wheel at high speed (circumferential speed is greater than 20 meters / secular generally reach Ra0.63. For different polishing processes: coarse polishing (basic polishing process), medium polishing (finish process ) and fine polishing (breeze process), selecting an appropriate polishing wheel can make the best polishing effect and improve polishing efficiency at the same time.

two. Sand

The cleaning and coarse process of the substrate surface using the impact of the high -speed sand flow. Use compressed air as a power to form a high -speed jet beam to spray spray (copper ore sand, quartz sand, cartilage, iron sand, Hainan sand) at high speed on the surface of The part that must be transformed, so that the surface or shape of the external surface of the room surface changes. The surface of the part, thus improving resistance to the fatigue of the room, the increase and the coating.

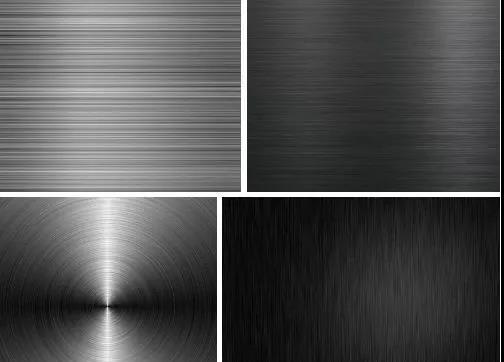

3. Brushed

It is a surface treatment method that forms lines on the surface of the part by grinding the product to obtain a decorative effect. Depending on the different models after the drawing, they can be divided into: drawing in a straight line, random drawing, corrugated drawing and rotary drawing. The surface wire drawing is a surface treatment method that forms wire patterns on the surface of the room by grinding the product to obtain a decorative effect. Because surface brushing can reflect the texture of metal materials, it has been loved by more and more users and is increasingly used.

Four. Anodization

An electrolytic oxidation process in which the surfaces of aluminum and aluminum alloys are generally converted into an oxide film, which has protective, decorative and other functional characteristics. Anodization of aluminum from this definition includes only part of the training process of an anodized film. An oxide film is formed on the surface of a metal or an alloy in the form of anode by electrolysis. Metal oxide films modify the surface condition and properties, such as surface shade, improve corrosion resistance, improve wear and hardness resistance and protect metal surfaces. For example, aluminum anodization, aluminum and its alloy are placed in the corresponding electrolyte (such as sulfuric acid, chromic acid, oxalic acid, etc.) as anode and electrolyzed in specific conditions and the current applied. Aluminum or its anode alloy is oxidized, and a thin layer of alumina is formed on the surface, with a thickness of 5 to 30 microns, and the hard anode oxide film can reach 25 to 150 Microns. Anodized aluminum or its alloy improves its hardness and wear resistance, up to 250 ~ 500 kg / mm square, with good heat resistance, and the fusion point of the hard anodized film is as high as 2320K, with excellent insulation and impact resistance. The tension through is as high as 2000V, which improves corrosion resistance and does not corrode for thousands of hours in Ω = 0.03 NaCl Salt Spray. The oxide film has a large number of micropores in the thin layer, which can adsorb various lubricants, which is suitable for the manufacture of engine cylinders or other wear resistant parts; and beautiful colors. Non -ferrous metals or their alloys (such as aluminum, magnesium and their alloys, etc.) can be anodized. In general, the anode is made of aluminum or aluminum alloy like the anode, and the cathode is made of lead plate, and the aluminum and lead plate is placed together in the aqueous solution. etc., and electrolyze to allow aluminum and lead plates. Among these acids, the most common is anodization with sulfuric acid.

Process flow

Monochrome color, gradient: polishing / sand / wire wire → oil elimination → anodization → neutralization → dying → seal → drying

Two-color: ① Polishing drawing / sand / wire wire → Oil elimination → Boundage → Anodizing 1 → Anodization 2 → Scelli → Drying

② Polishing drawing / sand / wire → Oil elimination → Anodization 1 → Laser engraving → Anodization 2 → Ferce de hole → Drying

Technical characteristics

1. Increase the intensity,

2.. Make any color except white.

3. Make a nickel -free seal to meet the requirements of European and American countries without nickel.

5. Electrophoresis

The processes are divided into electrophoresis on the anode and electrophoresis of cathode. If the paint particles are negatively loaded, the piece is an anode and the coating particles placed on the piece to form a film under the action of the power of the electric field is called anode electrophoresis; is cathode, and the coating particles placed on the play to form a film is called the electrophoresis of cathode.

The general flow of the process of electrophoresis on the anode is: pre -treatment of parts (oil elimination → Washing of hot water → elimination of bare → Washing of cold water → Phosphation → Washing of the ‘ Hot water → Passivation) → Electrophoresis on the anode → Positive post-treatment (clean water washing → Drying).

1. Remove the oil. The solution is generally a solution for thermal alkaline chemical degrease with a temperature of 60 ℃ (steam heating) and a time of approximately 20 minutes.

2. Wash in hot water. The temperature is 60 ℃ (steam heating), the weather is 2 minutes.

3. Remove the rust. Use H2SO4 or HCL, for example, with a solution to remove hydrochloric acid, the total HCL acidity is ≥ 43 points; Free acidity> 41 points;

4. Wash in cold water. Wash in cold water for 1 minute during traffic.

5. Phosphation. Phosphate is phosphate at medium temperature (phosphate for 10 minutes at 60 ° C), and phosphide liquid can be used as a finished finished product.

The above steps can also be replaced by the hoof → water washing.

6. Passivation. Use drugs that correspond to liquid phosphide (provided by the liquid phosphide manufacturer for sale) and only 1 to 2 minutes at room temperature.

7. Electrophoresis on the anode. Composition of electrolyte: H08-1 Black electrophoretic paint, solid mass fraction from 9% to 12%, fraction of distilled water mass from 88% to 91%. Voltage: (70 ± 10) V; Time: 2 to 2.5 minutes; Note that the entrance to the part and the output grooves must be extinguished. During electrophoresis, the current will gradually decrease as the paint film thickens.

8. Wash with clean water. Wash in cold water.

9. Dry. Cook in an oven at a temperature of (165 ± 5) ℃ for 40 to 60 minutes.

VI.PVD

PVD is the abbreviation of the physical steam deposit in English. And its reaction products are deposited on the part using the acceleration of the electric field. Physical steam deposit technology has a simple process, improved the environment, no pollution, few consumables, uniform and dense film formation and a strong bond with the substrate. This technology is widely used in aerospace, electronics, optics, machines, construction, light industry, metallurgy, materials and other fields, and can be prepared with wear resistance, Corrosion resistance, decoration, conductivity, insulation, light guide, piezoelectric, magnetic, magnetic, lubricating, film layers with superconductive characteristics.

7. Electroplast

(Electroplate) is the veneer process of a thin layer of other metals or alloys on certain metallic surfaces using electrolysis. Oxidation (such as rust), improves wear resistance, conductivity, reflectivity, corrosion resistance (copper sulfate, etc.) and improves aesthetics. The external layer of many parts is also electroplated.

eight. Engraving

The commonly known engraving is also called photochemical engraving. Convex or hollow molding.

Process flow:

Exhibition method: The project draws the size of the preparation based on graphics – Material preparation – Material cleaning – Drying → Film or coating → Drying → Exhibition → Development → Drying – Engraving → Removal of the film → OK

Screen printing method: cut → board cleaning (other stainless steel metal materials) → screen printing → engraving → scroll → ok

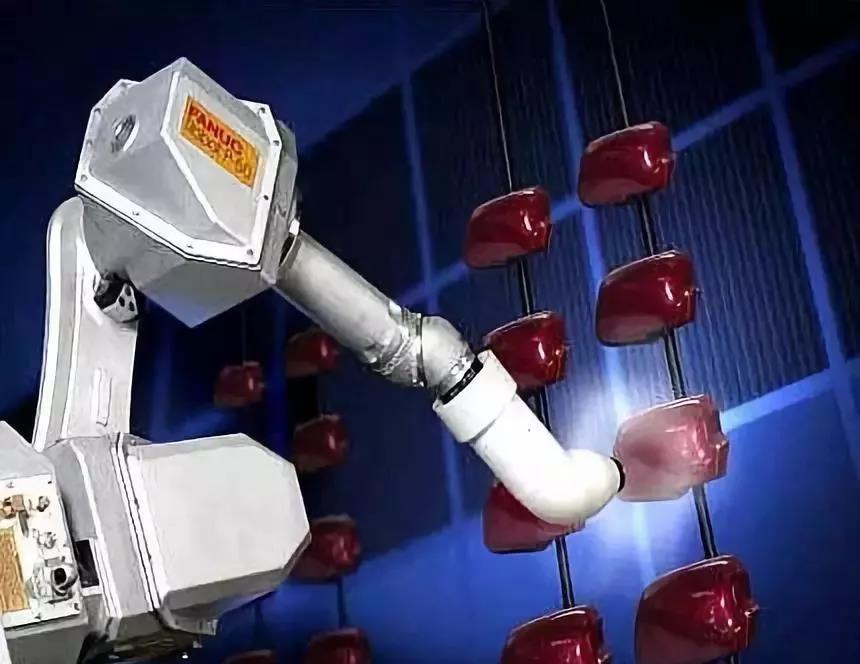

9. Spray

The spraying method is applied to the surface of the object coated by a spray gun or a disk atomizer, and dispersed in uniform and fine mist of mist by means of pressure or centrifugal force. It can be divided into air spraying, airless spraying, electrostatic spraying and various methods derived from basic spray forms above, such as atomization spray with high pressure at high pressure, thermal spray, spray automatic, multi-group spraying, etc. The spraying operation has high production efficiency and is suitable for the production of manual and industrial automation. The spray operation requires environmental requirements There are dust -free workshops from one million to a hundred levels, and spray equipment includes spray pistols, paint rooms, paint supply rooms, ovens of Drying / drying ovens, a spraying part of the transport part, mist equipment and wastewater, waste treatment equipment, etc. High flow and low -pressure atomization spraying are low atomization air pressure and a low jet jet speed. The paint rate increased from 30% to 40% of ordinary air spraying at 65% to 85%. Spray the finish on the surface of the leather with a spray gun or a light leather finish sprayer.

Ten.

Also known as laser engraving or laser marking, it is a process that uses optical principles to carry out surface treatment.

The high intensity focus laser beam emitted by the laser is originally. The substance must be caused by light energy.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.